Alkali-soluble light-curing epoxy resin containing cinnamic acid or coumarin groups, preparation method of resin and solder resist prepared by using same

An epoxy resin and coumarin-based technology, which is applied in the field of light-curing solder resist preparation, can solve the problems of low adhesion, poor development, and poor light-curing effect of copper-clad laminates, and reduce the influence of cured film performance. Effect of improving storage stability and excellent photocuring properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

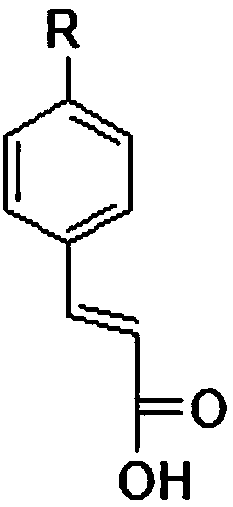

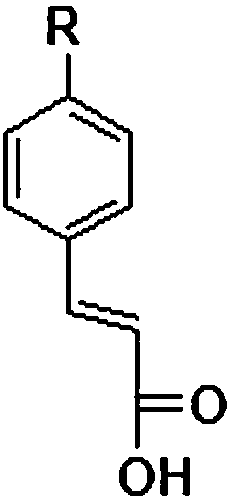

[0049] Under nitrogen protection, add 80g of diethylene glycol ethyl ether acetate into a 1000mL three-necked flask equipped with a stirrer, raise the temperature to 90°C, add 195.5g of epoxy resin NPCN-704, and keep the temperature for one hour to fully dissolve it, then cool down to 70°C and add 139.2g of cinnamic acid dissolved in 100g of diethylene glycol ether acetate (DCAC) (the molar ratio of epoxy group to cinnamic acid is: 1:1), raise the temperature to 80°C and add in 2g of diethylene glycol diethyl ether acetate (DCAC). The catalyst 4-dimethylaminopyridine in ethylene glycol diethyl ether acetate (DCAC) was 0.6 g, the temperature was raised to 105° C. and kept at a constant temperature for one hour, then the temperature was raised to 115° C. and kept at a constant temperature for 9 hours. Then the reaction system was cooled to 95° C., and 71.5 g of tetrahydrophthalic anhydride dissolved in 100 g of diethylene glycol ether acetate (DCAC) was added (the molar ratio of ...

Synthetic example 2

[0051] Under nitrogen protection, add 80g of diethylene glycol ethyl ether acetate into a 1000mL three-necked flask equipped with a stirrer, raise the temperature to 90°C, add 195.5g of epoxy resin NPCN-704, and keep the temperature for one hour to fully dissolve it, then cool down to 70°C and add 152.4g of 4-methylcinnamic acid dissolved in 100g of diethylene glycol ether acetate (DCAC) (the molar ratio of epoxy group to 4-methylcinnamic acid is: 1:1), and heat up to Add 0.8 g of catalyst 4-dimethylaminopyridine dissolved in 2 g of diethylene glycol diethyl ether acetate (DCAC) at 80°C, raise the temperature to 105°C and keep the temperature constant for one hour, then raise the temperature to 115°C and keep the temperature constant for 8 hours. Then the reaction system was cooled to 95°C, and 143.0 g of tetrahydrophthalic anhydride dissolved in 100 g of diethylene glycol ethyl ether acetate (DCAC) was added (the molar ratio of 4-methylcinnamic acid to unsaturated anhydride wa...

Synthetic example 3

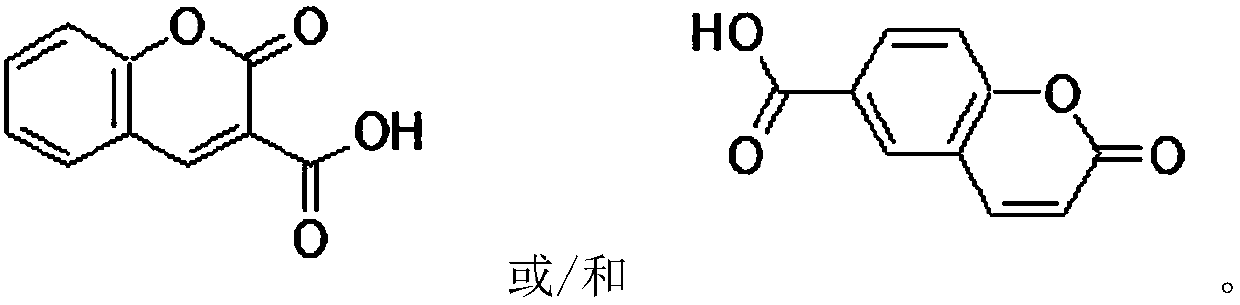

[0053] Under nitrogen protection, add 80g of diethylene glycol ethyl ether acetate into a 1000mL three-necked flask equipped with a stirrer, raise the temperature to 90°C, add 195.5g of epoxy resin NPCN-704, and keep the temperature for one hour to fully dissolve it, then cool down to 70°C and add 178.6g 3-carboxycoumarin dissolved in 100g diethylene glycol ether acetate (DCAC) (the molar ratio of epoxy group to 3-carboxycoumarin is: 1:1), and the temperature is raised to Add 0.6 g of catalyst 4-dimethylaminopyridine dissolved in 2 g of diethylene glycol diethyl ether acetate (DCAC) at 80°C, raise the temperature to 105°C and keep the temperature constant for one hour, then raise the temperature to 115°C and keep the temperature constant for 9 hours. Then the reaction system was cooled to 95°C, and 71.5g of tetrahydrophthalic anhydride dissolved in 100g of diethylene glycol ethyl ether acetate (DCAC) was added (the molar ratio of 3-carboxycoumarin to unsaturated acid anhydride ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com