Sealant composite and sealant

A composition and sealant technology, applied in the directions of adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of marine biological erosion, colloid cracking, and can not be effectively anti-fouling and anti-mildew sealing for a long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0013] In one embodiment of the present invention, substances such as 8-methyl-N-vanillyl-6-nonenamide are added to the sealant system, especially the silicone sealant system, as an antifouling agent, so that it has a good long-term effect on the substrate. Effective antifouling effect. The main mechanism of action of the antifouling agent is to force the external adsorbent to fail to attach through its own irritation, so as to achieve the antifouling effect.

[0014] In one embodiment of the present invention, the crosslinking agent may be methyl triethoxysilane, methyl tributylketoxime silane, vinyl tributylketoxime silane, ethyl silicate and the like.

[0015] In one embodiment of the present invention, the filler may be calcium carbonate, talc powder, titanium dioxide, ceramic microspheres, clay, diatomaceous earth, kaolin, silicon dioxide and the like.

[0016] In one embodiment of the present invention, the pigment can be iron red, cyanochrome yellow, blue powder, carbo...

Embodiment 1

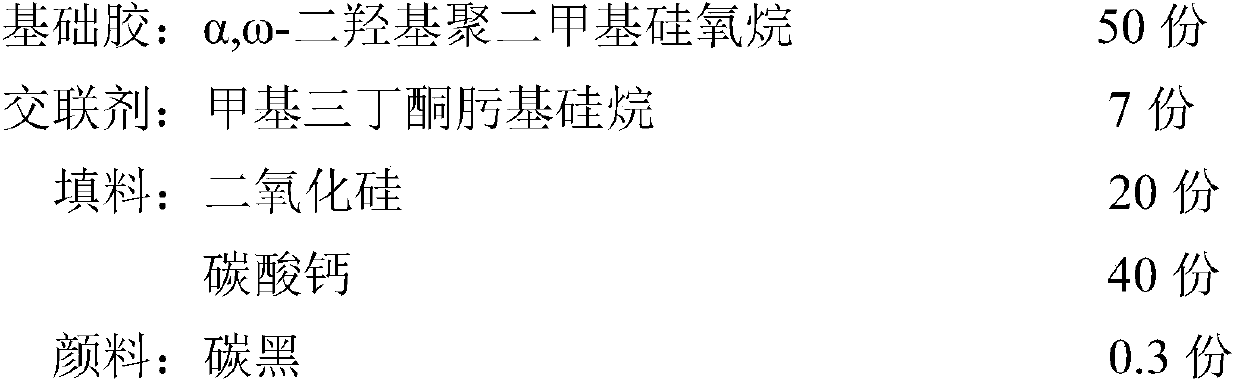

[0027] The sealant of this embodiment is made from the following components by mass:

[0028]

[0029]

[0030] Take 10 parts of base glue, 10 parts of antifouling agent and 10 parts of antifungal agent and vacuumize and stir in a double planetary mixer, the vacuum degree is -0.09MPa~-0.1MPa, the stirring speed is 50r / min, and the stirring time is 30~50min , dispersed evenly as a small antifouling agent for later use.

[0031] The production of silicone sealants is carried out according to the conventional process. First, the liquid raw materials are added to the kettle according to the formula ratio, and then the fillers are added in turn. After high-speed dispersion and stirring, the prepared additives are added. The small antifouling agent is cleaned up at the last time When dry powder is added, gray silicone sealant can be obtained.

Embodiment 2

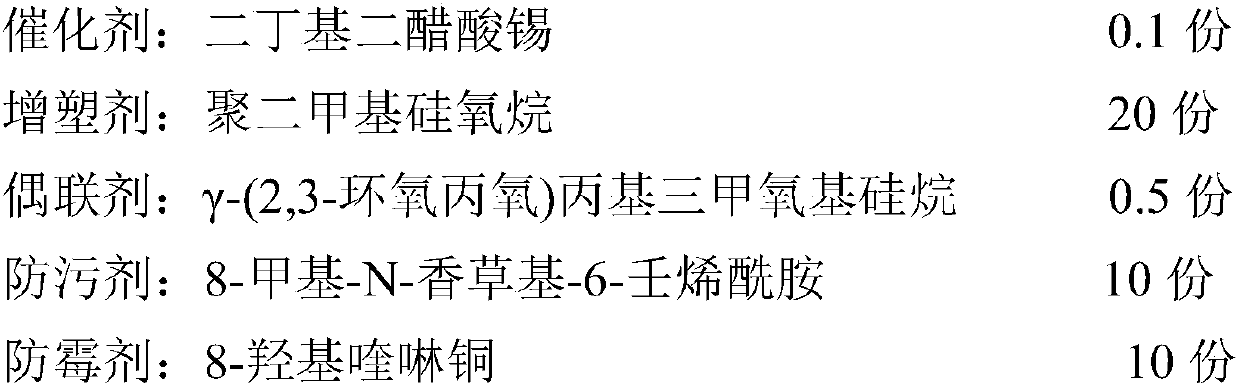

[0033] The sealant of this embodiment is made from the following components by mass:

[0034]

[0035] Concrete production technology is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com