A down feather dedusting agent and a preparing method thereof

A technology for dust removal agent and down, which is applied in the field of down processing, can solve the problems of low washing efficiency of detergents, damage to down structure, water pollution, etc., and achieve the effects of good biodegradability, less irritation and pollution reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

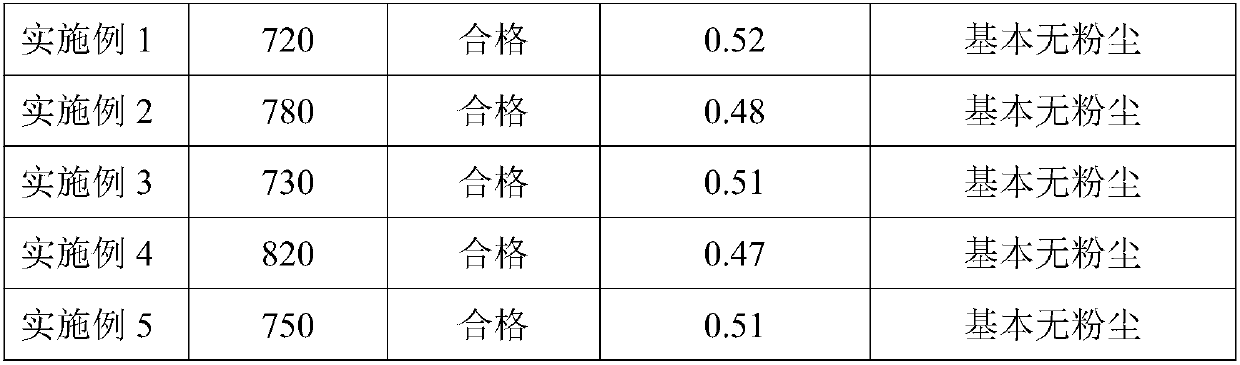

Examples

Embodiment 1

[0014] After heating 20 parts of deionized water to 50°C, add 3 parts of polyvinyl benzyl trimethyl quaternary ammonium salt, 6 parts of fatty alcohol polyoxyethylene ether carboxylate, and coconut acid in sequence under constant stirring. 2 parts of diethanolamide, 0.5 part of almond oil amide propyl amine oxide, 2 parts of sodium lauryl sulfate, 1 part of sodium citrate and 2 parts of chitosan were added after stirring for 2 minutes. After stirring for 3 minutes, add double 3 parts of tallow carbethoxyl hydroxyethyl methyl ammonium methyl sulfate, stir for 10 minutes, add 8 parts of antibacterial agent, 0.5 part of tea tree essential oil and 3 parts of tea oil after cooling to room temperature, and stir for 8 minutes to obtain down dust remover.

[0015] The preparation method of the antibacterial agent is as follows: mix 5 parts of mugwort, 2 parts of wild chrysanthemum, 1 part of purslane, 4 parts of cork, 1 part of magnolia officinalis, and 2 parts of Indigo Naturalis, and th...

Embodiment 2

[0017] After heating 40 parts of deionized water to 50°C, add 5 parts of polyvinyl benzyl trimethyl quaternary ammonium salt, 10 parts of fatty alcohol polyoxyethylene ether carboxylate, and coconut acid in sequence under constant stirring. 6 parts of diethanolamide, 1 part of almond oil amide propyl amine oxide, 5 parts of sodium lauryl sulfate, 2 parts of sodium citrate and 4 parts of chitosan were added after stirring for 2 minutes. After stirring for 3 minutes, add double 6 parts of tallow carboethyl hydroxyethyl methyl ammonium methyl sulfate, stir for 10 minutes, add 12 parts of antibacterial agent, 0.5 part of lavender essential oil and 5 parts of tea oil after cooling to room temperature, and stir for 8 minutes to obtain down dust remover.

[0018] The antibacterial agent is prepared by mixing 8 parts of mugwort, 5 parts of wild chrysanthemum, 2 parts of purslane, 6 parts of cork, 3 parts of magnolia officinalis, and 4 parts of Indigo Naturalis, and then adding 4 parts by ...

Embodiment 3

[0020] After heating 50 parts of deionized water to 50°C, add 4 parts of polyvinyl benzyl trimethyl quaternary ammonium salt, 8 parts of fatty alcohol polyoxyethylene ether carboxylate sodium, and coconut acid in sequence under constant stirring. 4 parts of diethanolamide, 0.8 parts of almond oil amide propyl amine oxide, 3 parts of sodium lauryl sulfate, and after stirring for 2 minutes, add 1.5 parts of sodium citrate and 3 parts of chitosan. After stirring for 3 minutes, add double 4.5 parts of tallow carboethyl hydroxyethyl methyl ammonium methyl sulfate, stirring for 10 minutes, adding 10 parts of antibacterial agent, 0.5 parts of geranium essential oil and 4 parts of tea oil after cooling to room temperature, and stirring for 8 minutes to obtain down dust remover.

[0021] The preparation method of the antibacterial agent is: mix 6 parts of mugwort, 3 parts of wild chrysanthemum, 1.5 parts of purslane, 5 parts of cork, 2 parts of magnolia officinalis, and 3 parts of Indigo N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com