Preparation method of semi-finished vegetable product

A technology for semi-finished products and vegetables, applied in the field of preparing semi-finished vegetables, can solve the problems of uneconomical economy, expensive raw materials, waste of energy, etc., and achieve the effects of increasing shelf life, improving sensory performance and technical performance, and reducing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1 Verification experiment of vegetable semi-finished product manufacturing process conditions

[0016] A kind of preparation method of semi-finished Chinese cabbage, carries out according to the following steps:

[0017] (1) Select fresh cabbage, and bleach it in 0.005-0.06% isocitric acid sodium salt solution or sodium carbonate solution at 80-105°C for 5 minutes;

[0018] (2) Bleaching in a sorbic acid solution with a mass concentration of 0.03-0.12% for 1 min, then adding anhydrous calcium chloride to dry at 40-130°C until the dry matter content is 40-60%, and finally cooling to 20°C.

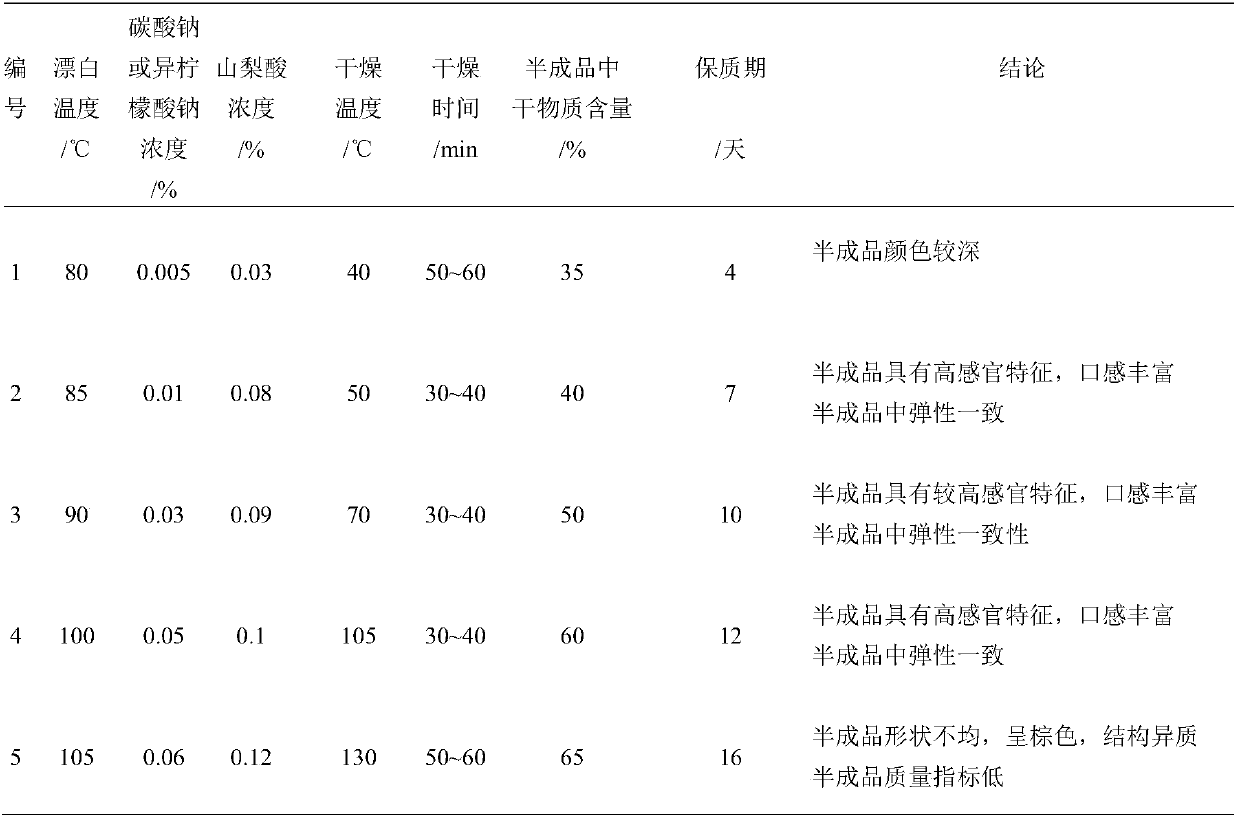

[0019] The specific preparation conditions and results are shown in Table 1:

[0020] Table 1

[0021]

[0022] Note 1: Shelf life refers to the shortest shelf life of semi-finished products in vacuum packaging.

[0023] From the analysis of the conclusions in Table 1, it can be seen that the experimental conclusions of the second group and the fourth group are the be...

Embodiment 2

[0031] A kind of preparation method of semi-finished Chinese cabbage, carries out according to the following steps:

[0032] (1) Select fresh cabbage, and bleach it in 0.05% isocitric acid sodium salt solution or sodium carbonate solution at 100°C for 5 minutes;

[0033] (2) Bleach in 0.1% 3,4,6-tribenzyloxy-D-glucal solution for 1 min, then add desiccant to dry at 105°C until the dry matter content is 60%, and finally cool to 20°C.

[0034] The shelf life of the above semi-finished cabbage under vacuum is 22 days, which is obviously better than that of the fourth group in Example 1, which proves that bleaching with 3,4,6-tribenzyloxy-D-glucal has the effect of extending the protection period.

Embodiment 3

[0036] A kind of preparation method of semi-finished Chinese cabbage, carries out according to the following steps:

[0037] (1) Select fresh cabbage, and bleach it in 0.05% isocitric acid sodium salt solution or sodium carbonate solution at 100°C for 5 minutes;

[0038] (2) Bleach in chrysanthemic acid solution with a mass concentration of 0.1% for 1 min, then add a desiccant to dry at 105°C until the dry matter content is 60%, and finally cool to 20°C.

[0039] The shelf life of the semi-finished Chinese cabbage under vacuum is 23 days, which is obviously better than that of the fourth group in Example 1, which proves that the use of chrysanthemic acid for bleaching has the effect of prolonging the protection period.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com