Three-dimensional porous gold-solver-platinum ternary alloy nanometer material as well as preparation method and application thereof

A ternary alloy, three-dimensional porous technology, applied in the direction of nanotechnology, nanotechnology, metal processing equipment, etc., can solve the problems of low catalytic activity, long reaction cycle, poor stability, etc. Simple and easy to operate, the effect of improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Specifically, the preparation method of the three-dimensional porous gold-silver-platinum ternary alloy nanomaterial may include the following steps:

[0034] Step A. Mix potassium chloroplatinate, ascorbic acid, and gold@silver nanocube colloidal solution together so that the concentration of potassium chloroplatinate in the mixed liquid is 0.0001-0.0005mol / L, and the concentration of ascorbic acid is 0.001-0.004mol / L, and reacted for 0.5 to 1 hour to prepare a colloidal solution of gold@silver platinum nanocubes. Wherein, the gold@silver nanocube colloidal solution is a gold@silver nanocube colloidal solution in an ethylene glycol system. In practical applications, the preparation method of the gold@silver nanocube may include the following steps:

[0035](1) Step A1, adding chloroauric acid and polydiallyl dimethyl ammonium chloride with a molecular weight of 100,000 to 200,000 in the ethylene glycol solution, so that the concentration of chloroauric acid in the mi...

Embodiment 1

[0048] Such as figure 1 As shown, a three-dimensional porous gold-silver-platinum ternary alloy nanomaterial is prepared by following steps:

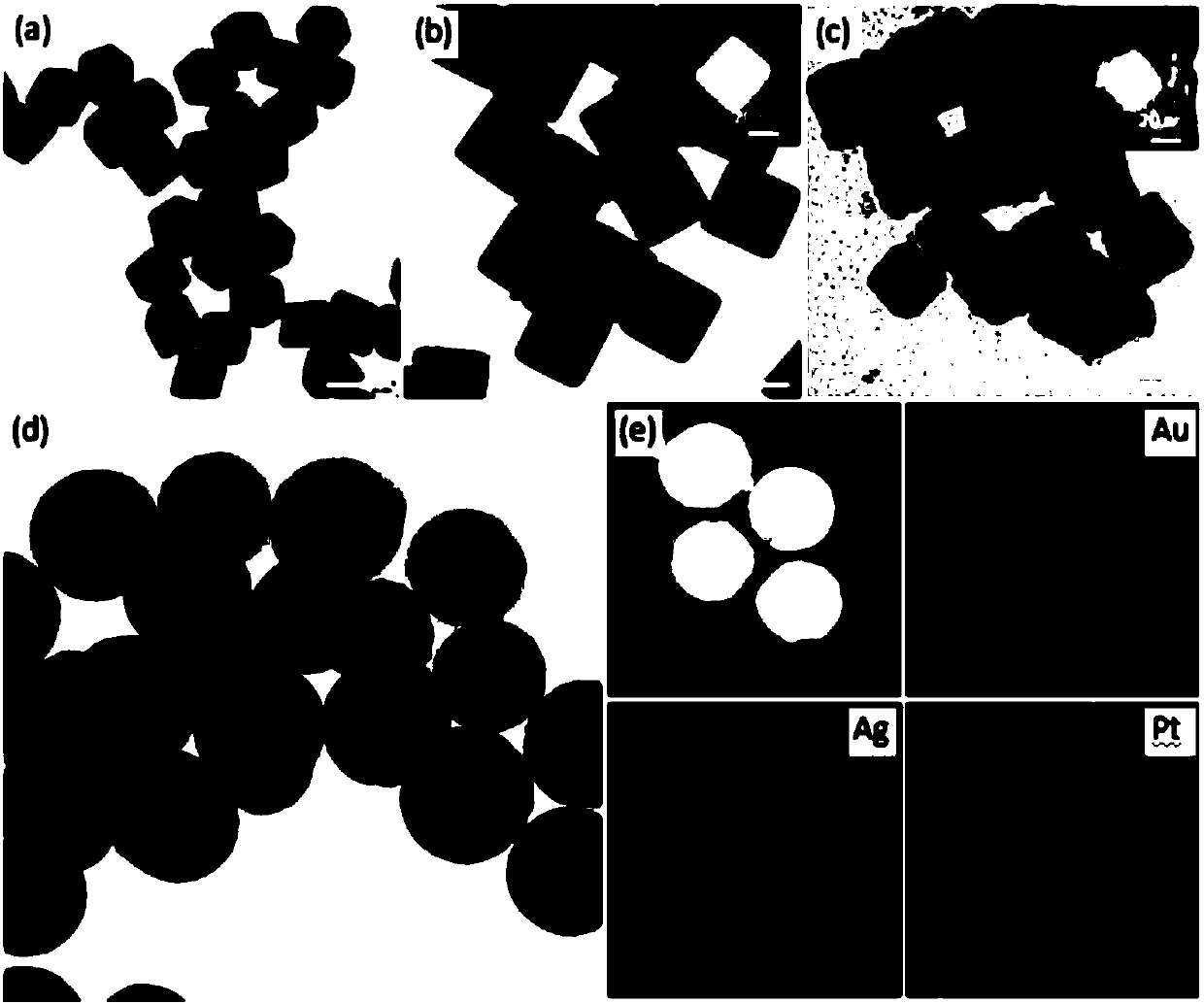

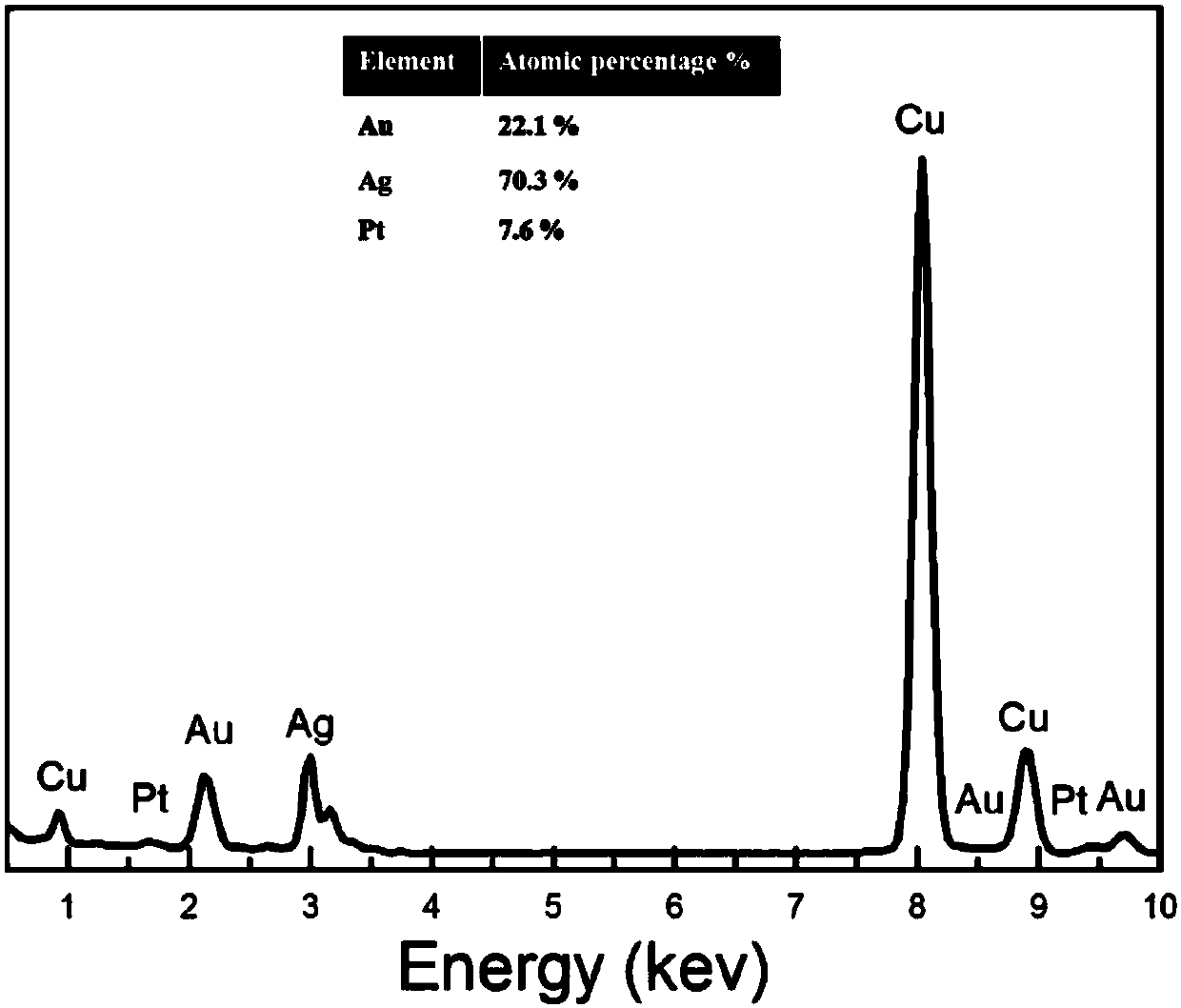

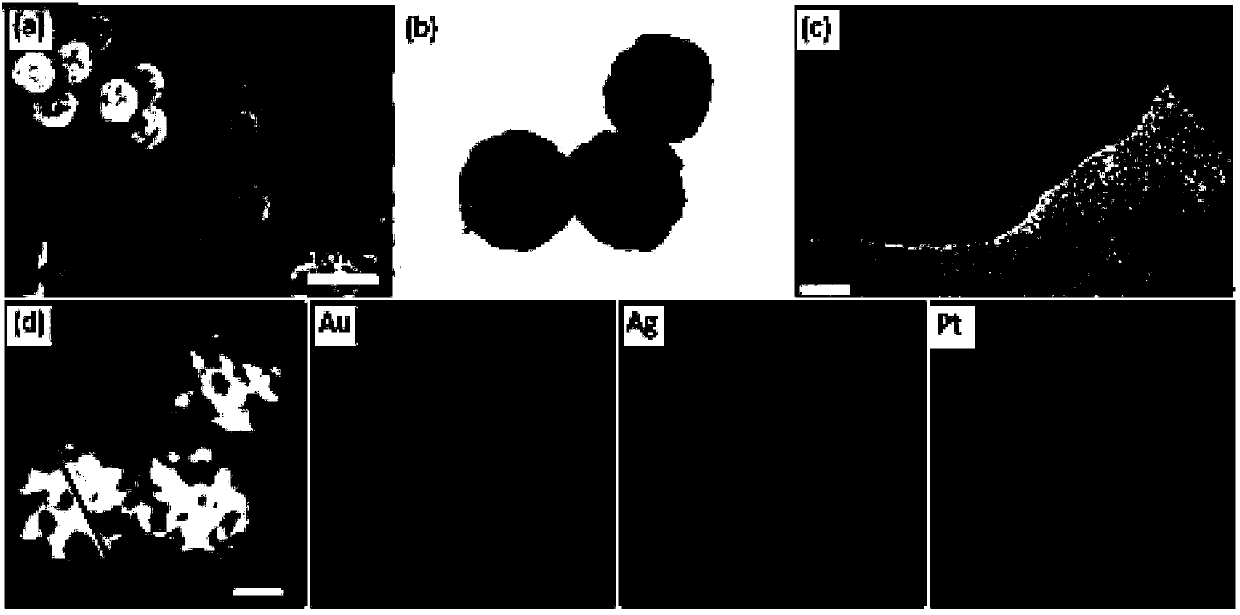

[0049] Step a, inject an appropriate amount of 20wt% polydiallyldimethylammonium chloride aqueous solution (wherein, the molecular weight of polydiallyldimethylammonium chloride is 100000~200000) into 70ml ethylene glycol solution, Add chloroauric acid solution and stir evenly, make the concentration of chloroauric acid in the liquid after mixing be 0.0005 mol / liter, the concentration of polydiallyl dimethyl ammonium chloride be 0.025 mol / liter, then at 220 ℃ Reaction under the conditions for 1 hour, naturally cooled to room temperature, thereby making gold nano-octahedral colloidal solution; wherein, the transmission electron micrograph of gold nano-octahedron can be as follows figure 1 as shown in a.

[0050] Step b, at room temperature, add silver nitrate and ascorbic acid aqueous solution to 70ml of the gold nano-octahedral colloi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com