A kind of preparation method of calcined dolomite powder

The technology of dolomite powder and dolomite, which is applied in the field of building materials, can solve the problems of high energy consumption, complex production process, low efficiency, etc., and achieve the effects of low energy consumption, simple method and favorable volume stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

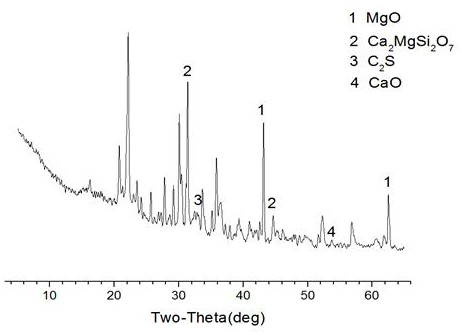

Embodiment 1

[0025] The preparation method of calcined dolomite powder in the present embodiment, comprises the following steps:

[0026] (1) Use a crusher to crush the dolomite to less than 1mm;

[0027] (2) Mix silica powder and crushed dolomite evenly at a mass ratio of 0.5:1, SiO in silica powder 2 The content is 95%;

[0028] (3) Calcinate the above mixture at 1150°C for 2 hours, take it out and cool it naturally;

[0029] (4) Grinding the cooled calcined product through a sieve with an aperture of 75 μm to obtain the calcined dolomite powder.

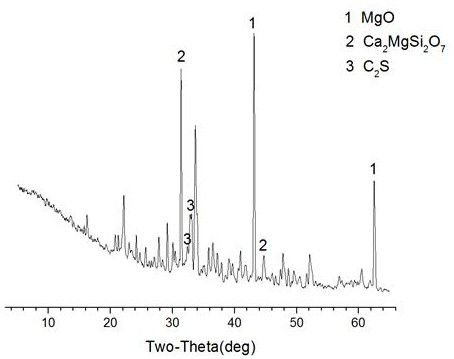

Embodiment 2

[0031] The preparation method of calcined dolomite powder in the present embodiment, comprises the following steps:

[0032] (1) Use a crusher to crush the dolomite to less than 1mm;

[0033] (2) Mix silica fume and broken dolomite evenly at a mass ratio of 1:1, SiO in silica fume 2 The content is 85%;

[0034] (3) Calcinate the above mixture at 1300°C for 3 hours, take it out and cool it naturally;

[0035] (4) Grinding the cooled calcined product through a sieve with an aperture of 75 μm to obtain the calcined dolomite powder.

Embodiment 3

[0037] The preparation method of calcined dolomite powder in the present embodiment, comprises the following steps:

[0038] (1) Use a crusher to crush the dolomite to less than 1mm;

[0039] (2) Mix diatomite and crushed dolomite evenly in a mass ratio of 2.5:1, SiO in diatomite 2 The content is 75%;

[0040] (3) Calcinate the above mixture at 1650°C for 1.5h, take it out and cool it naturally;

[0041] (4) Grinding the cooled calcined product through a sieve with an aperture of 58 μm to obtain the calcined dolomite powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com