Water-soluble unsaturated polyester and photocurable composition

An unsaturated, water-soluble technology, applied in polyester coatings, textiles and papermaking, coatings, etc., can solve the problems of high cost, weak initiation efficiency, unsatisfactory coating performance, etc., to achieve inhibition of hydrolysis, high initiation Efficiency, excellent water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

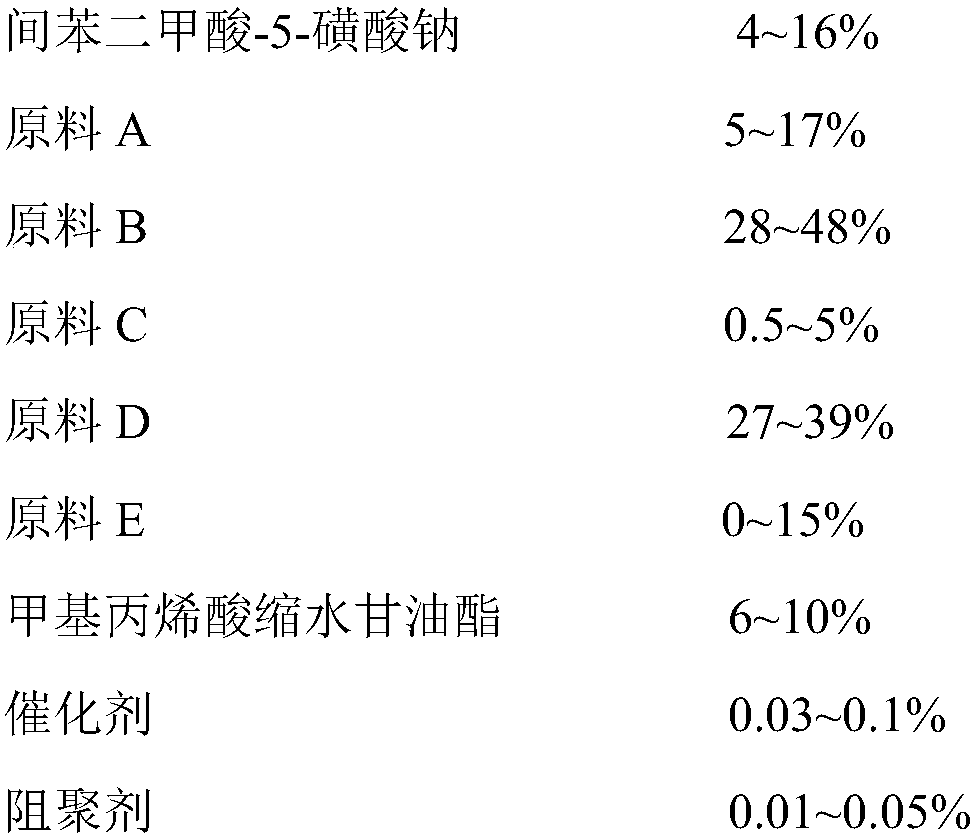

[0059] The water-soluble unsaturated polyester provided in this embodiment is mainly made of the following raw materials in parts by mass:

[0060]

[0061] Its synthesis method is as follows:

[0062] (1) Carry out bulk melt esterification reaction of isophthalic acid-5-sodium sulfonate and raw material A under a catalyst and an inert atmosphere. After the system is heated up to form esterified water, the temperature is slowly raised to 180-190°C and kept for 1-2 hour to obtain a hydrolysis-resistant water-soluble oligomer with an acid value of 25 mgKOH / g;

[0063] (2) The hydrolysis-resistant water-soluble oligomer in step (1) is cooled to below 130°C, and raw material B, raw material C, raw material D, raw material E and polymerization inhibitor are added according to the dosage relationship, and the temperature is raised to the reaction system to produce esterification After soaking in water, slowly raise the temperature to 200-210°C and keep it warm for 1-2 hours, the...

Embodiment 2

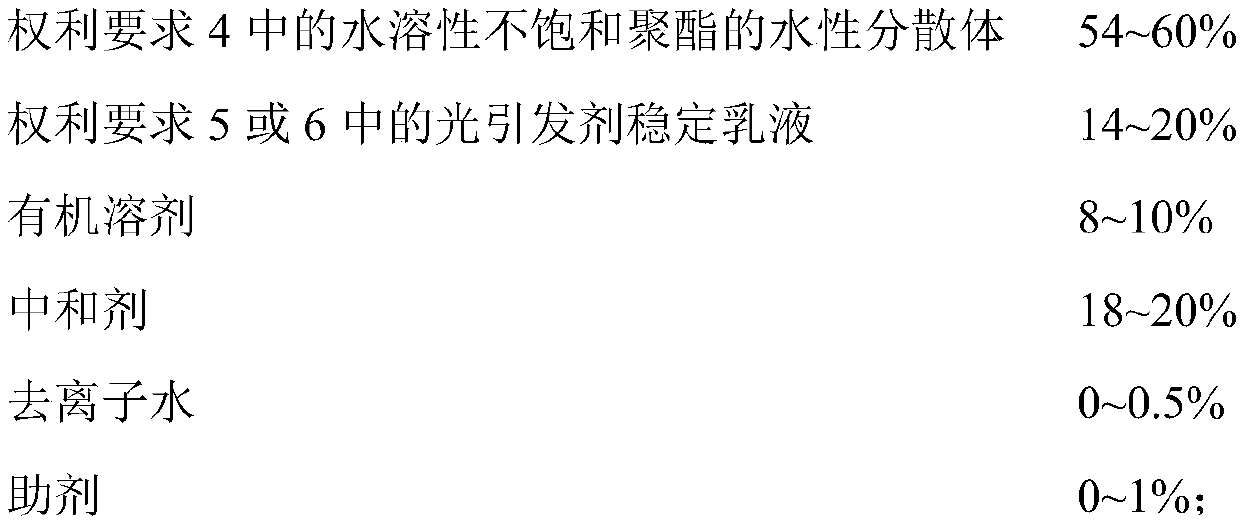

[0083] The water-soluble unsaturated polyester provided in this embodiment is mainly made of the following raw materials in parts by mass:

[0084]

[0085] Its synthesis method is as follows:

[0086] (1) Carry out bulk melt esterification reaction of isophthalic acid-5-sodium sulfonate and raw material A under a catalyst and an inert atmosphere. After the system is heated up to form esterified water, the temperature is slowly raised to 180-190°C and kept for 1-2 hour to obtain a hydrolysis-resistant water-soluble oligomer with an acid value of 25 mgKOH / g;

[0087] (2) The hydrolysis-resistant water-soluble oligomer in step (1) is cooled to below 130° C., raw material B, raw material C, raw material D, raw material E and a polymerization inhibitor are added, and the temperature is raised until the reaction system produces esterified water, Slowly raise the temperature to 200-210°C and keep it warm for 1-2 hours, then cool it down to 150-160°C and keep it warm for 1-2 hour...

Embodiment 3

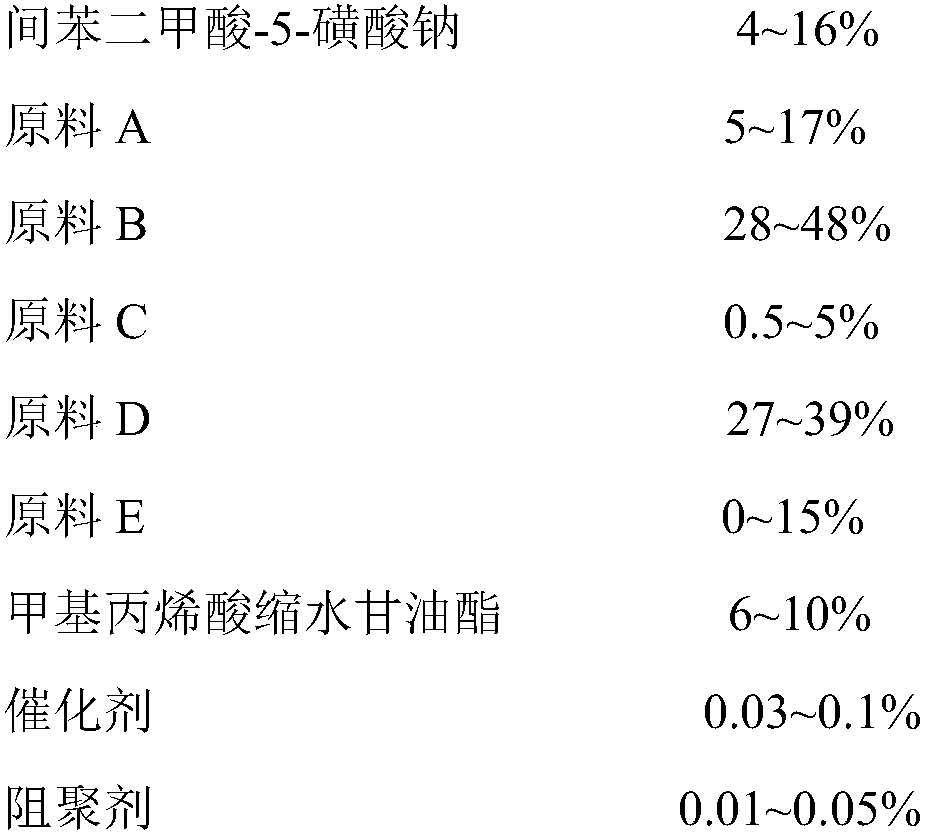

[0093] The water-soluble unsaturated polyester provided in this embodiment is mainly made of the following raw materials in parts by mass:

[0094]

[0095] Its synthesis method is as follows:

[0096] (1) Carry out bulk melt esterification reaction of isophthalic acid-5-sodium sulfonate and raw material A under a catalyst and an inert atmosphere. After the system is heated up to form esterified water, the temperature is slowly raised to 180-190°C and kept for 1-2 hour to obtain a hydrolysis-resistant water-soluble oligomer with an acid value of 24mgKOH / g;

[0097] (2) The hydrolysis-resistant water-soluble oligomer in step (1) is cooled to below 130° C., raw material B, raw material C, raw material D, raw material E and a polymerization inhibitor are added, and the temperature is raised until the reaction system produces esterified water, Slowly raise the temperature to 200-210°C and keep it warm for 1-2 hours, then cool down to 150-160°C and keep it warm for 1-2 hours un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com