High-permeability, high-weather-resistance and environment-friendly silicon-fluorine protecting liquid and preparation method thereof

A silicon fluoride emulsion, an environmentally friendly technology, applied in coatings, biocide-containing paints, antifouling/underwater coatings, etc., can solve the problem that the protective layer cannot achieve the surface antifouling effect, the surface antifouling ability is reduced, and the surface is hydrophobic Performance degradation and other problems, to achieve excellent high and low temperature resistance, good stain resistance, and avoid pollution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

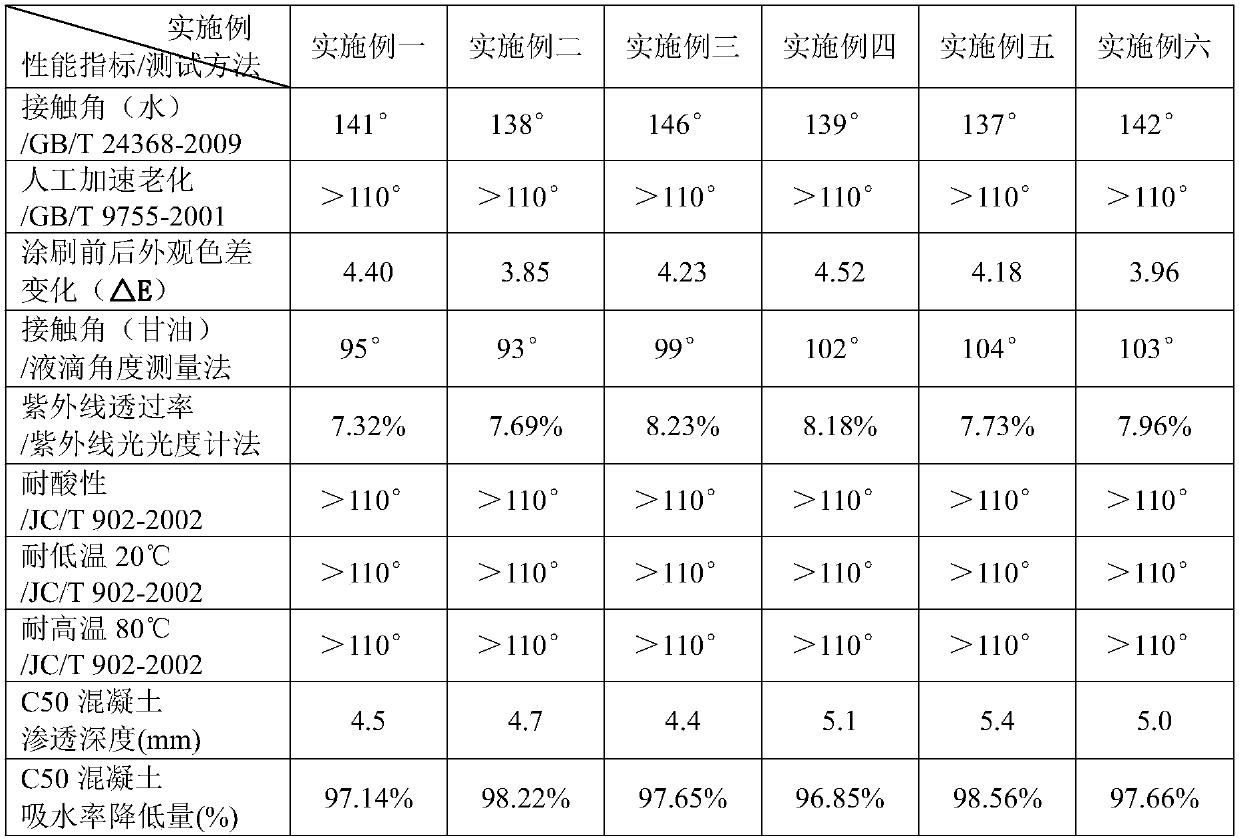

Examples

Embodiment 1

[0040] In this embodiment, a high-permeability, high-weather-resistance and environment-friendly silicon fluoride emulsion, the steps are as follows:

[0041] (1) Preparation of silane emulsion

[0042] Weigh 30g of isobutyltrimethoxysilane and 0.6g of composite silicone emulsifier (0.3g each of OP10 and NP10), pour it into a container, heat it in a water bath to 25°C, stir at a speed of 1000r / min for 30min, and prepare A liquid ;

[0043] Weigh 0.4g of composite silicone emulsifier (0.2g each of OP10 and NP10) into 19g of deionized water, and stir at 25°C for 30min at a speed of 1000r / min to prepare liquid B;

[0044]Then, under the stirring state of 1000r / min, slowly drop the above-mentioned liquid A into the liquid B at the speed of 0.1-0.3mL / s; Stirring at 25°C for 30min at a stirring speed of 1000r / min to prepare a silane emulsion;

[0045] (2) Preparation of Fluoroalkylsiloxane Emulsion

[0046] Weigh 10 g of tridecafluorooctyltrimethoxysilane and 0.25 g of perfluoro...

Embodiment 2

[0051] In this embodiment, a high-permeability, high-weather-resistance and environment-friendly silicon fluoride emulsion, the steps are as follows:

[0052] (1) Preparation of silane emulsion

[0053] Weigh 40g of isobutyltriethoxysilane, 2g of composite silicone emulsifier (1g each of sodium dodecylsulfonate and span20), pour into a container, heat to 35°C in a water bath, and stir for 40min at a speed of 1500r / min , to prepare liquid A;

[0054] Weigh 1 g of composite silicone emulsifier (0.5 g each of sodium lauryl sulfonate and span20) into 22 g of deionized water, stir at 30 °C for 35 min at a speed of 2000 r / min to prepare liquid B;

[0055] Then, under the stirring state of 3000r / min, slowly drop the above-mentioned liquid A into the liquid B at the speed of 0.1-0.3mL / s; Stirring at 35°C for 60min at a stirring speed of 1000r / min to prepare a silane emulsion;

[0056] (2) Preparation of Fluoroalkylsiloxane Emulsion

[0057] Weigh 13g of tridecafluorooctyltriethoxy...

Embodiment 3

[0062] In this embodiment, a high-permeability, high-weather-resistance and environment-friendly silicon fluoride emulsion, the steps are as follows:

[0063] (1) Preparation of silane emulsion

[0064] Weigh 50g of octyltriethoxysilane and 1g of composite silicone emulsifier (each 0.5g of Pingpingjia 15 and AEO9), pour it into a container, heat it in a water bath to 45°C, and stir at a speed of 1500r / min for 90min to prepare A liquid;

[0065] Weigh 0.5g of composite silicone emulsifier (0.25g each of Pingpingjia 15 and AEO9) into 14g of deionized water, and stir at 35°C at a speed of 2000r / min for 70min to obtain liquid B;

[0066] Then, under the stirring state of 1000r / min, slowly drop the above-mentioned liquid A into the liquid B at the speed of 0.1-0.3mL / s; Stirring at 60°C for 60min at a stirring speed of 1500r / min to prepare a silane emulsion;

[0067] (2) Preparation of Fluoroalkylsiloxane Emulsion

[0068] Weigh 15g of pentafluorononyltrimethoxysilane and 1g of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com