Staphylococcus albus powder and application thereof

A technology of staphylococcus albus and staphylococcus, applied in the field of microorganisms, can solve the problem of high fermentation cost of staphylococcus albus, achieve the effect of increasing industrial added value, high industrial added value, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of Staphylococcus albus powder, which is prepared by inoculating the seed liquid of Staphylococcus albus into a wheat bran medium for fermentation;

[0030] Specifically, the staphylococcus albus powder is prepared according to the following process:

[0031] 1) Take Staphylococcus albus solution (5×10 7 CFU / mL), according to the inoculum amount of 3%, inoculated into the seed medium, 30°C, 100rpm shaker culture for 18h, to obtain the seed liquid; the components of the seed medium are: glucose 12g / L, agar 7g / L , peptone 3g / L, KH 2 PO 4 0.5g / L, K 2 HPO 4 0.5g / L, MgSO 4 0.1g / L, FeSO 4 0.1g / L, pH7.5;

[0032] 2) Inoculate the seed liquid with 5% inoculum amount in a fermenter with 50L wheat bran medium for fermentation culture, culture temperature is 30°C, ventilation rate keeps dissolved oxygen level at 20%, and sugar content is controlled by adding glucose The amount is not less than 0.2wt%, and it is fermented and cultivated for 54 hours to obtain Sta...

Embodiment 2

[0039] A kind of Staphylococcus albus powder, which is prepared by inoculating the seed liquid of Staphylococcus albus into a wheat bran medium for fermentation;

[0040] Specifically, the staphylococcus albus powder is prepared according to the following process:

[0041] 1) Take Staphylococcus albus solution (7×10 7 CFU / mL), inoculated into the seed medium according to the inoculation amount of 2%, and cultured on a shaker at 32°C and 100rpm for 24 hours to obtain the seed liquid; the components of the seed medium were: glucose 12g / L, agar 7g / L , peptone 3g / L, KH 2 PO 4 0.5g / L, K 2 HPO 4 0.5g / L, MgSO 4 0.1g / L, FeSO 4 0.1g / L, pH7.5;

[0042]2) Inoculate the seed liquid with 3% inoculum amount in a fermenter with 50L wheat bran medium for fermentation and culture, the culture temperature is 32°C, the ventilation rate keeps the dissolved oxygen level at 20%, and the sugar content is controlled by adding glucose The amount is not less than 0.2wt%, fermented and culti...

Embodiment 3

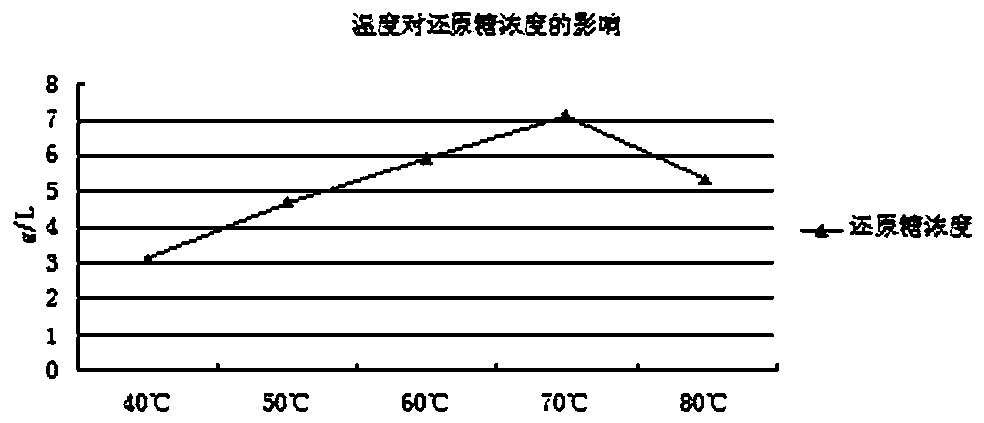

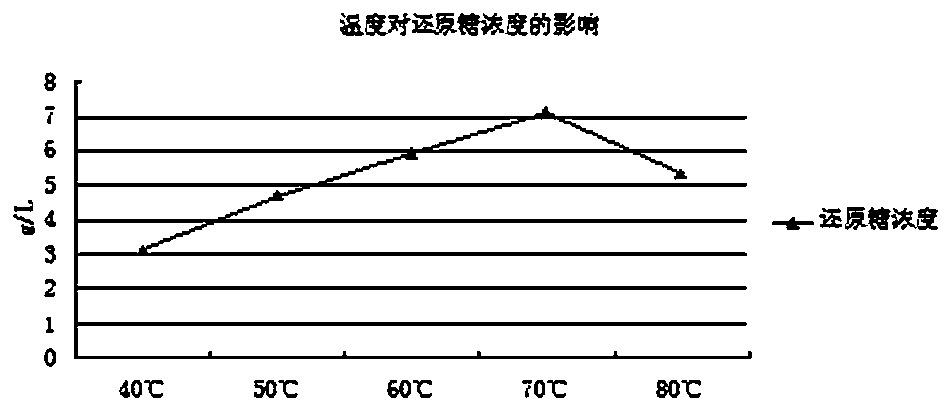

[0049] Nitrosalicylic acid colorimetric method detects the content of reducing sugar in component A:

[0050] Taking Example 1 as an example, the influence of temperature and the amount of enzyme added on the reducing sugar content was detected, and the temperature gradient was set as: 40°C, 50°C, 60°C, 70°C, 80°C; the enzyme amount gradient was set as: 0.2U / g, 0.4U / g, 0.6U / g, 0.8U / g, 1.0U / g. Such as figure 1 As shown, when the temperature is lower than 70°C, as the temperature rises, the content of reducing sugar increases, and at about 70°C, the content of reducing sugar obtained by hydrolysis is the highest, indicating that the activity of mesophilic amylase at 70°C can be Reaching a relatively high level; while the temperature of 80 ℃ reducing sugar content decreased sharply, this may be because the high temperature reduces the activity of amylase at medium temperature, and it may also be accompanied by the consumption of a large amount of reducing sugar. Such as figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com