Method and application for removing arsenic from black copper sludge

A black copper mud and arsenic removal technology, applied in the field of arsenic removal, can solve the problems of reducing equipment production capacity, endangering workers' health, affecting metal direct recovery rate and product quality, and achieving good benefits and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

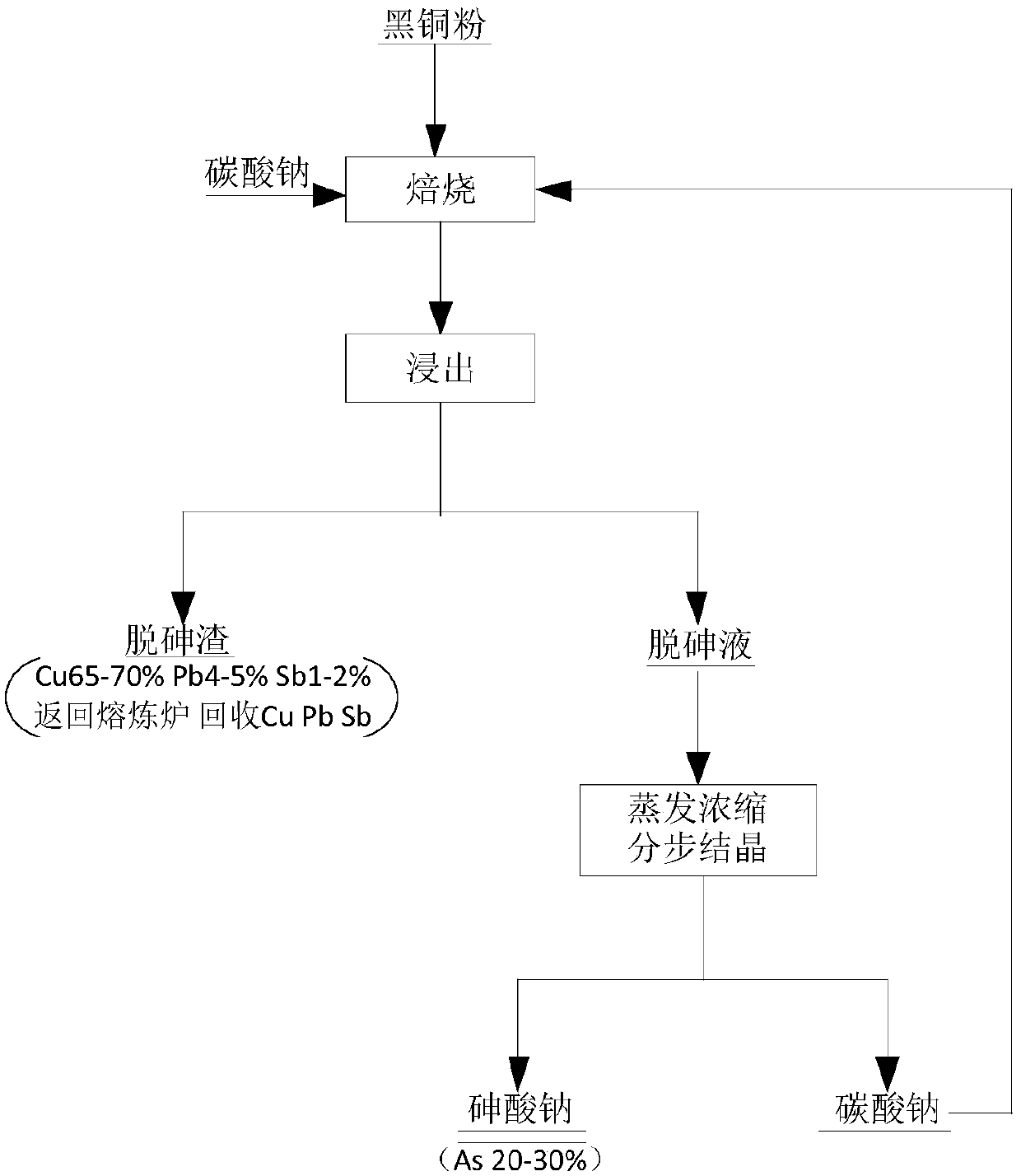

Method used

Image

Examples

Embodiment 1

[0029] The present embodiment provides a method for removing arsenic from black copper mud, which mainly includes:

[0030] Mix the black copper mud and sodium carbonate at a mass ratio of 1:1.2, and roast the reaction for 2 hours at a temperature of 600° C. to obtain a roasted product;

[0031] The roasted product and water were mixed at a solid-to-liquid ratio of 1g:5mL, reacted at a temperature of 75°C for 3.5 hours, and filtered to separate the solid and liquid to obtain arsenic-removed residue and arsenic-removed liquid.

[0032] Among them, the arsenic removal liquid contains: As 27.00g / L, Pb 0.52g / L, Bi 0.03g / L; the arsenic removal residue contains: Cu70.65%, As 0.64%, Pb 3.25%, Ni 1.68%, Sb 1.18%, Bi 0.35%. The dissolution rate of As was 97.81%, the recovery rate of Pb was 85.12%, Cu, Ni, Sb all entered into the arsenic removal residue.

[0033] Use a vacuum rotary evaporator to evaporate and concentrate the arsenic-removing liquid, and crystallize for the first time...

Embodiment 2

[0036] The present embodiment provides a method for removing arsenic from black copper mud, which mainly includes:

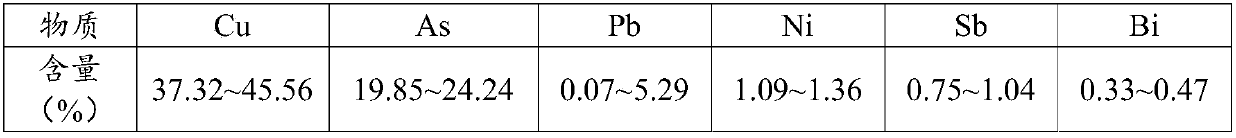

[0037] Mix black copper mud and sodium carbonate at a mass ratio of 1:0.9, and roast at a temperature of 650°C for 1 hour to obtain a roasted product; wherein, the material composition of black copper mud is: Cu 44.33wt%, As 21.59wt %, Pb 2.71wt%, Ni 1.09wt%, Sb 0.83wt%, Bi 0.37wt%.

[0038] The calcined product was pulverized and ground to 70 mesh. Mix the calcined product with a solid-to-liquid ratio of 1g:3mL and water, react at a temperature of 75°C for 2 hours, with a stirring intensity of 200rpm, and filter to separate the solid and liquid to obtain arsenic-removing slag and arsenic-removing liquid.

[0039] Among them, the arsenic removal solution contains: As 27.86g / L, Pb 0.43g / L, Bi 0.02g / L; the arsenic removal residue contains: Cu72.42%, As 0.63%, Pb 3.72%, Ni 1.45%, Sb 1.28%, Bi 0.65%. The dissolution rate of As is 98.01%, the recovery rate of Pb i...

Embodiment 3

[0043] The present embodiment provides a method for removing arsenic from black copper mud, which mainly includes:

[0044]Mix the black copper mud and sodium carbonate at a mass ratio of 1:1.2, and roast the reaction at a temperature of 650°C for 2 hours to obtain a roasted product; wherein, the material composition of the black copper mud is: Cu 44.33wt%, As 21.59wt% %, Pb 2.71wt%, Ni 1.09wt%, Sb 0.83wt%, Bi 0.37wt%.

[0045] The roasted product was pulverized and ground to 80 mesh. Mix the roasted product with a solid-to-liquid ratio of 1g:8mL and water, react at a temperature of 80°C for 2 hours, and stir at 250rpm, and filter to separate the solid and liquid to obtain arsenic-removing slag and arsenic-removing liquid.

[0046] Among them, the arsenic removal solution contains: As 28.00g / L, Pb 0.50g / L, Bi 0.04g / L; the arsenic removal residue contains: Cu72.05%, As 0.74%, Pb 3.89%, Ni 1.82%, Sb 1.39%, Bi 0.57%. The dissolution rate of As was 98.53%, the recovery rate of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com