Method of preparing high heat dissipating ceramic package substrate

A ceramic packaging and ceramic substrate technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of poor bonding between conductive lines and ceramic substrates, high production costs, and complicated process routes. To achieve the effect of ensuring product yield, avoiding ceramic cracking and conductive line falling off, and simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing a high heat dissipation ceramic packaging substrate, comprising the following steps:

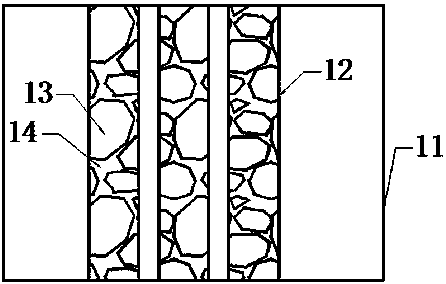

[0035] S1, as attached figure 1 As shown, the cleaned aluminum nitride ceramic substrate 11 is placed on the platform of a marking machine with a laser of 355nm, and according to the set circuit pattern, the 5J / cm 2 The laser energy density was used to mark the ceramic substrate 10 times in the air atmosphere, so that a mixture layer with a metallized circuit pattern 12 was formed on the marking line. The thickness of the mixture layer was 4 μm, and the mixture layer was composed of alumina 13 and aluminum 14. Areas of the ceramic substrate that are not laser marked remain insulated.

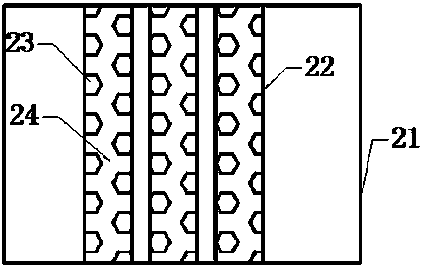

[0036] S2, as attached figure 2 As shown, the aluminum nitride ceramic substrate 21 that has been marked and formed a mixture layer of a metallized circuit pattern is immersed in an electroless copper plating solution at 55° C. for electroless copper plating. The soaking time i...

Embodiment 2

[0041] S1, as attached figure 1 As shown, the cleaned aluminum nitride ceramic substrate 11 is placed on the platform of a marking machine with a laser of 355nm, and according to the set circuit pattern, the 20J / cm 2engrave the ceramic substrate 5 times in the air atmosphere, so that a mixture layer of metallized circuit pattern 12 is formed on the marked circuit, the thickness of the mixture layer is 3 μm, and the mixture layer is composed of alumina 13 and aluminum 14. Areas of the ceramic substrate that are not laser marked remain insulated.

[0042] S2, as attached figure 2 As shown, the aluminum nitride ceramic substrate that has been marked and formed a mixture layer of a metallized circuit pattern is immersed in an electroless copper plating solution at 60°C for electroless copper plating. The immersion time is 25 minutes, so that the marked circuit area forms about A 6 μm thick bonding layer composed of oxide and elemental metal, the oxide is cuprous oxide 23 , and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com