Lithium manganate composite manganous-manganic oxide and industrial preparation method thereof

A three manganese tetroxide, composite technology, applied in chemical instruments and methods, manganese oxide/hydroxide, manganate/permanganate, etc., can solve problems such as incomplete oxidation, and avoid lattice oxygen. Defects, the effect of improving product performance and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

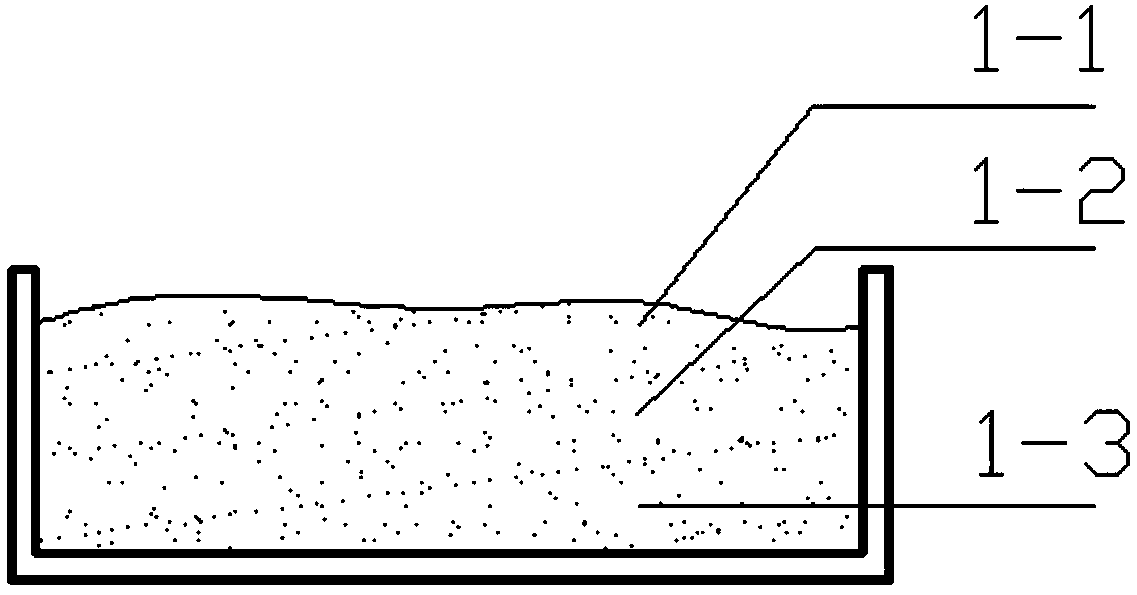

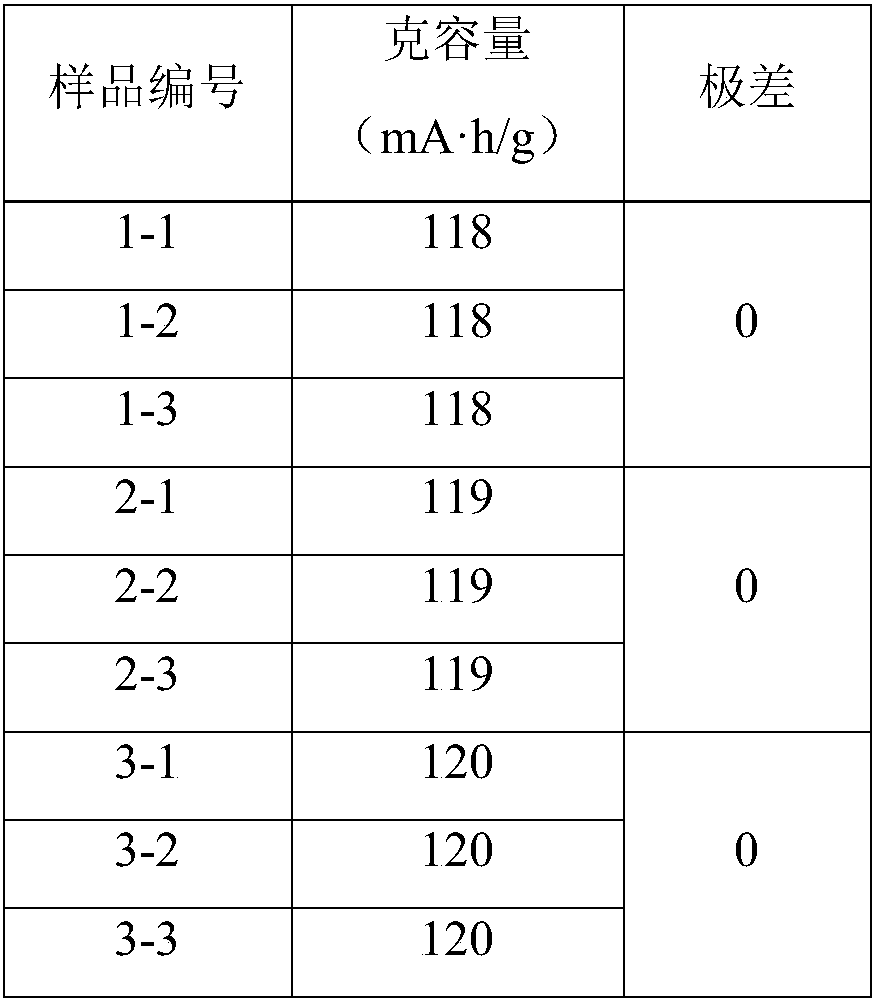

Embodiment 1

[0025] The high-purity metal manganese flakes are crushed to a median particle size of 250 μm by a roller machine, and the manganese powder above 350 μm is removed after being sieved by a vibrating sieve, and then mixed with a double-cone mixer for 2 hours, and 1000 kg of the above manganese powder is added to the 4m 3 In the reactor of pure water and 100kg ammonium sulfate, the air is oxidized, and the gas volume is controlled at 300m 3 / h, the stirring speed is controlled at 400r / min, after reacting at room temperature for 20h, add 600kg manganese chloride, add 800kg NaHCO after stirring for 10min 3 Continue to react for 3 hours, after the reaction finishes, the slurry is washed (Cl - Content<500ppm), after drying, trimanganese tetraoxide particles coated with manganese carbonate are obtained. Then the trimanganese tetraoxide is roasted in the air at 350° C. for 3 hours until the reaction is completed to obtain a composite trimanganese tetraoxide product 1 coated with mang...

Embodiment 2

[0030] Use a ball mill to crush the high-purity manganese metal flakes to a median particle size of 150 μm, remove the manganese powder above 200 μm after sieving through a vibrating screen, and then mix it with a double-cone mixer for 2 hours, then take 1000 kg of the above manganese powder and put it into 5m 3 In the reactor of pure water and 100kg ammonium chloride, the air is oxidized, and the gas volume is controlled at 200m 3 / h, the stirring speed is controlled at 300r / min, after reacting at room temperature for 20h, add 500kg manganese chloride, add 700kg NaHCO after stirring for 10min 3 Continue to react for 3 hours, after the reaction finishes, the slurry is washed (Cl - Content<500ppm), after drying, trimanganese tetraoxide particles coated with manganese carbonate are obtained. Then this trimanganese tetraoxide is roasted in the air at 350° C. for 3 hours until the reaction is completed to obtain a composite trimanganese tetraoxide product 2 coated with manganese ...

Embodiment 3

[0035]The high-purity metal manganese flakes are crushed to a median particle size of 20 μm by a mechanical pulverizer, and the manganese powder above 80 μm is removed after being sieved by a vibrating screen. 6m 3 In the reactor of pure water and 100kg ammonium chloride, the air is oxidized, and the gas volume is controlled at 100m 3 / h, the stirring speed is controlled at 200r / min, after reacting at room temperature for 20h, add 250kg manganese chloride, add 350kg NaHCO after stirring for 10min 3 Continue to react for 3 hours, after the reaction finishes, the slurry is washed (Cl - Content<500ppm), after drying, trimanganese tetraoxide particles coated with manganese carbonate are obtained. Then this trimanganese tetraoxide is roasted in air at 350° C. for 3 hours until the reaction is completed, and the composite trimanganese tetraoxide product 3 coated with manganese dioxide is obtained. Among the composite trimanganese tetraoxide products prepared by this method The bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com