A water-based release agent for high temperature resistant composite materials

A composite material, water-based technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve problems such as difficult demoulding, product surface pollution, no substantial improvement, etc., to achieve non-toxic side effects, good high temperature adhesion, The effect of less residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

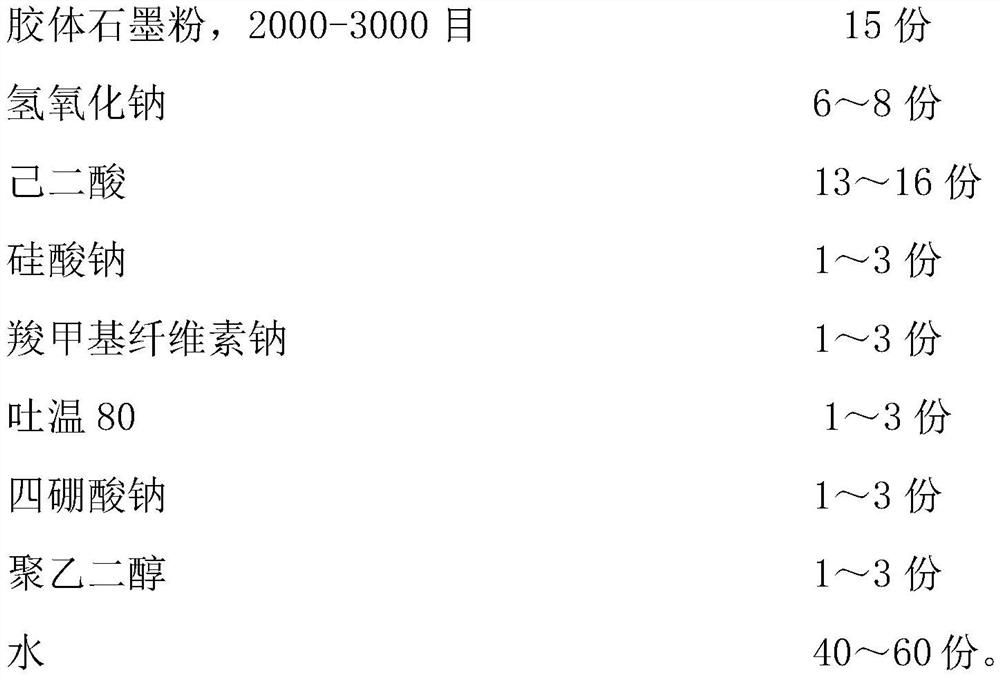

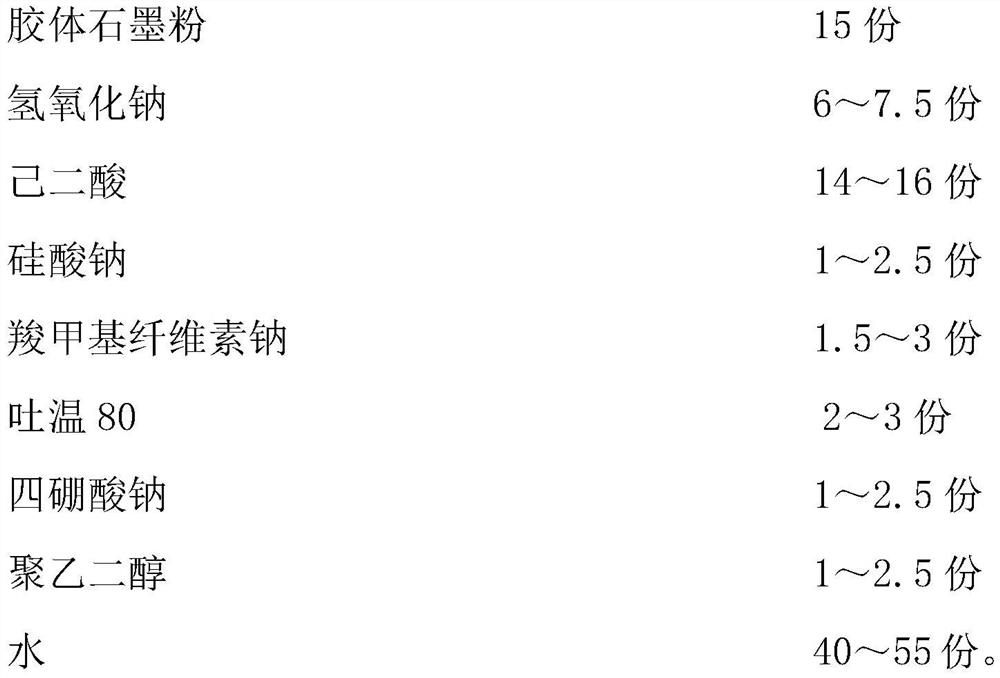

Method used

Image

Examples

Embodiment 1

[0052] Put 60 parts of water into the enamel bucket, start stirring, add 6 parts of sodium hydroxide, after the sodium hydroxide is dissolved, slowly add 13 parts of adipic acid and stir for 10 minutes. Add 1 part of polyethylene glycol (PEG6000), 1 part of sodium silicate, and 1 part of sodium tetraborate in sequence, and continue stirring for 10 minutes to completely dissolve them. Add 1 part of Tween 80, stir for 10 minutes, slowly add 2.3 parts of sodium carboxymethyl cellulose (FVH9) and stir for 30 minutes, the pH is 7.1, and finally, add 15 parts of colloidal graphite powder (Qingdao Dongkai Graphite Co., Ltd., 3000 mesh ), vigorously stirred for 60 minutes. Made into a black paste high temperature resistant composite material water-based release agent.

[0053] Use a clean cotton cloth to dip a small amount of high-temperature-resistant demoulding machine, apply it evenly on the inner surface of the mold, let it dry for 10 minutes, and after the solvent evaporates, th...

Embodiment 2

[0055] Put 40 parts of water into the enamel bucket, start stirring, add 8 parts of sodium hydroxide, after the sodium hydroxide is dissolved, slowly add 16 parts of adipic acid, and stir for 10 minutes. Add 3 parts of polyethylene glycol (PEG6000), 3 parts of sodium silicate and 3 parts of sodium tetraborate in sequence, and continue to stir for 10 minutes to completely dissolve it. Add 3 parts of Tween 80, stir for 10 minutes, slowly add 3 parts of sodium carboxymethyl cellulose (coating grade) and stir for 30 minutes, test the pH to 7.0, finally, add 15 parts of colloidal graphite powder (Qingdao Risheng Graphite Co., Ltd., 2000 mesh), vigorously stirred for 60 minutes. Made into a water-based release agent for high temperature resistant composite materials.

[0056] Use a clean cotton cloth to dip a small amount of high-temperature-resistant demoulding machine, apply it evenly on the inner surface of the mold, let it dry for 13 minutes, and after the solvent evaporates, t...

Embodiment 3

[0058] Put 55 parts of water into the enamel bucket, start stirring, add 7.5 parts of sodium hydroxide, after the sodium hydroxide is dissolved, slowly add 14 parts of adipic acid, and stir for 10 minutes. Add 2.5 parts of polyethylene glycol (PEG6000), 2.5 parts of sodium silicate (industrial grade), and 2.5 parts of sodium tetraborate in sequence, and continue stirring for 10 minutes to completely dissolve them. Add 2 parts of Tween 80, stir for 10 minutes, slowly add 1.5 parts of sodium carboxymethyl cellulose (industrial grade) and stir for 30 minutes, test the pH to 7.2, and finally, add 15 parts of colloidal graphite powder (Shenzhen Huanan Xinyang Technology Co., Ltd. company), vigorously stirred for 60 minutes. Made into a water-based release agent for high temperature resistant composite materials.

[0059] Use a clean cotton cloth to dip a small amount of high-temperature-resistant demoulding machine, apply it evenly on the inner surface of the mold, let it dry for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com