Modified asphalt with good high-temperature cohesiveness and preparation method thereof

A modified asphalt, cohesive technology, used in building insulation materials, building components, construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

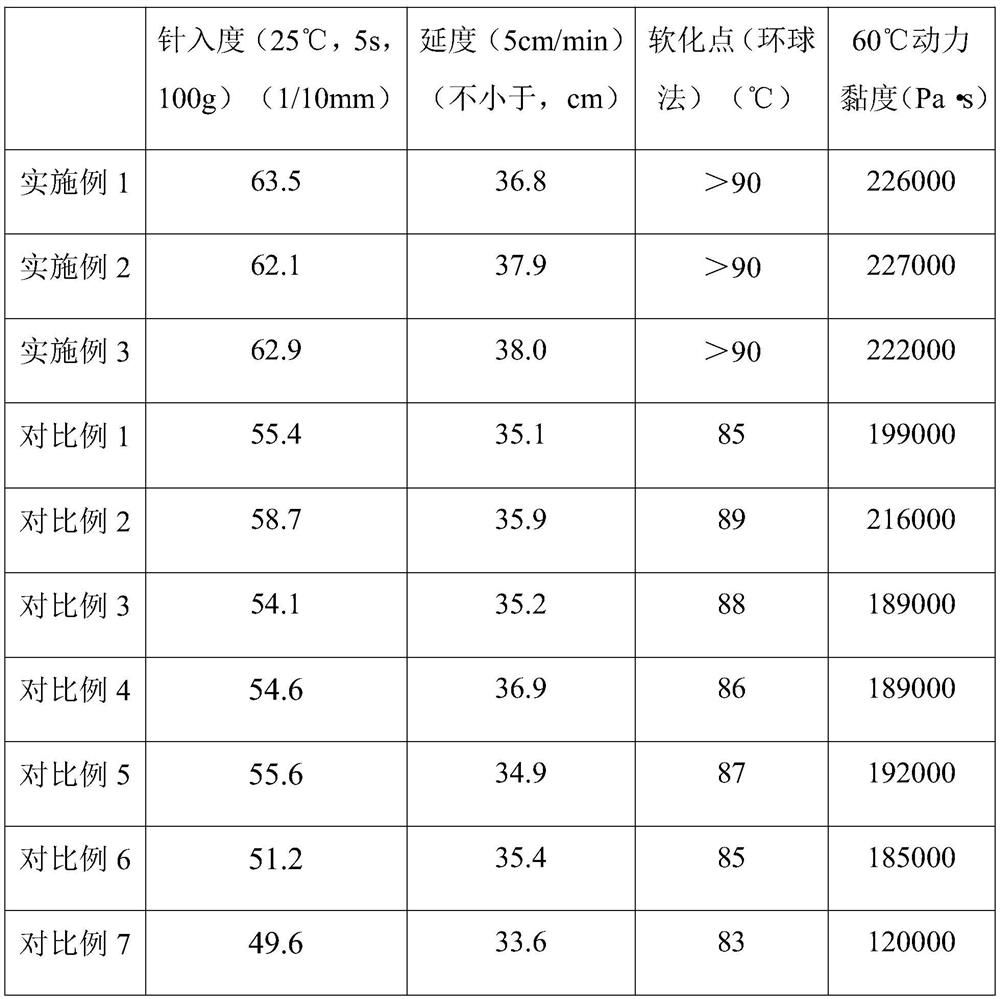

Examples

Embodiment 1

[0029](1) Mix cyclohexane, polyethylene glycol monomethyl ether, sodium hydroxide, anhydrous sodium sulfate and deionized water in a mass ratio of 2:3:0.5:0.02:6, purge with argon for 3 min, 40 After 1 h of reaction at ℃, p-chloromethylstyrene with 0.2 times the mass of cyclohexane was added dropwise at a rate of 3 ml / min, the temperature was raised to 60 ℃, the reaction was continued for 2 h, and finally extracted with deionized water once, and extracted with dichloromethane. 3 times and rotary steaming to obtain polyethylene oxide containing benzene ring; polyethylene glycol and tetrahydrofuran are mixed in a mass ratio of 1:2 and placed in an ice bath at 0°C, under nitrogen atmosphere, polyethylene oxide is added. The initiator boron trifluoride ethyl ether with 0.003 times the mass of alcohol was stirred for 15 min at 30 rpm, and propylene oxide with 0.05 times the mass of polyethylene glycol was added dropwise at a rate of 10 drops / s. After the reaction for 4 h, it was adj...

Embodiment 2

[0035] (1) Mix cyclohexane, polyethylene glycol monomethyl ether, sodium hydroxide, anhydrous sodium sulfate and deionized water in a mass ratio of 2:3.5:0.6:0.04:7, purge with argon for 4min, 45 After 1.5 hours of reaction at ℃, p-chloromethylstyrene with 0.4 times the mass of cyclohexane was added dropwise at a rate of 4 ml / min, the temperature was raised to 63 ℃, and the reaction was continued for 2.5 hours. Methane was extracted for 4 times and rotary steamed to obtain polyethylene oxide containing benzene ring; polyethylene glycol and tetrahydrofuran were mixed in a mass ratio of 1:3 and placed in an ice bath at 1 °C, under nitrogen atmosphere, added polyethylene oxide. The initiator boron trifluoride ether with 0.0034 times the mass of ethylene glycol was stirred for 25 min at 40 rpm, and propylene oxide with 0.1.3 times the mass of polyethylene glycol was added dropwise at a rate of 13 drops / s. Sodium bicarbonate was adjusted to pH 7, trihydroxymethyl propane with a mas...

Embodiment 3

[0041] (1) Mix cyclohexane, polyethylene glycol monomethyl ether, sodium hydroxide, anhydrous sodium sulfate and deionized water in a mass ratio of 2:4:0.8:0.05:8, purging with argon for 5 min, 50 After 2 hours of reaction at ℃, p-chloromethyl styrene with 0.5 times the mass of cyclohexane was added dropwise at a rate of 5 ml / min, the temperature was raised to 65 ℃, the reaction was continued for 3 hours, and finally extracted with deionized water once, and extracted with dichloromethane. 5 times and rotary steam to obtain polyethylene oxide containing benzene ring; polyethylene glycol and tetrahydrofuran are mixed in a mass ratio of 1:4 and placed in an ice bath at 2 °C, under nitrogen atmosphere, polyethylene oxide is added The initiator boron trifluoride ethyl ether with 0.005 times the mass of alcohol was stirred for 30 min at 50 rpm, and propylene oxide with 0.2 times the mass of polyethylene glycol was added dropwise at a rate of 15 drops / s. After 8 hours of reaction, it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com