Nutritional supplement for milking sows as well as preparation method and application thereof

A nutritional supplement and technology for nursing sows, applied in the field of animal feed, can solve the problems of lack of functional fatty acids in puffed soybean powder, unable to meet the nutritional needs of fatty acids, affect palatability and nutritional value, etc., to improve milk quality and prevent fat Effect of oxidative rancidity and improvement of lactation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

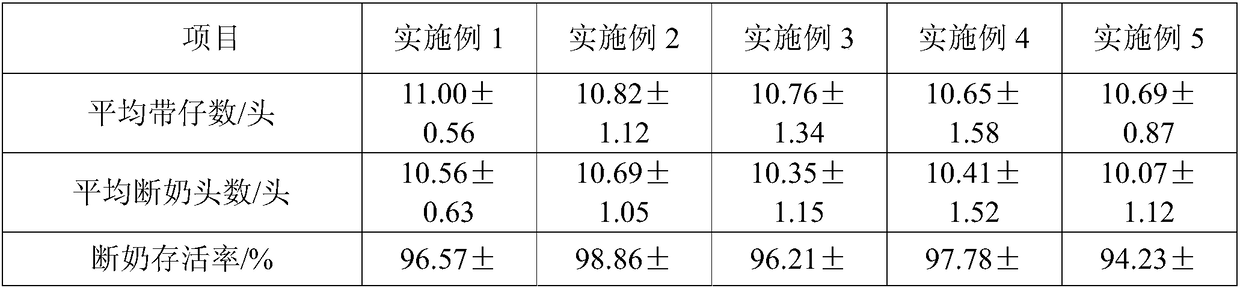

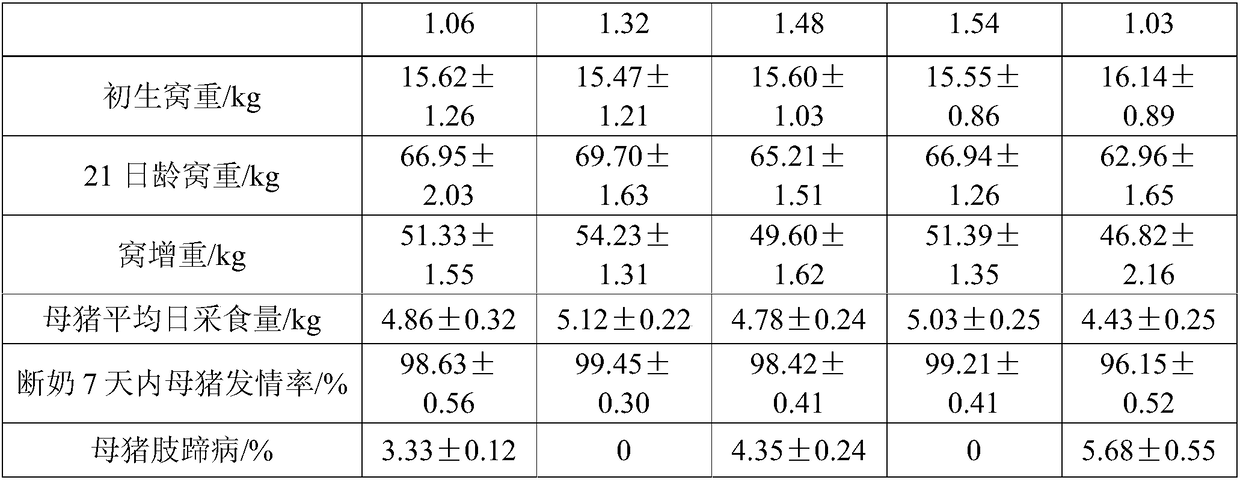

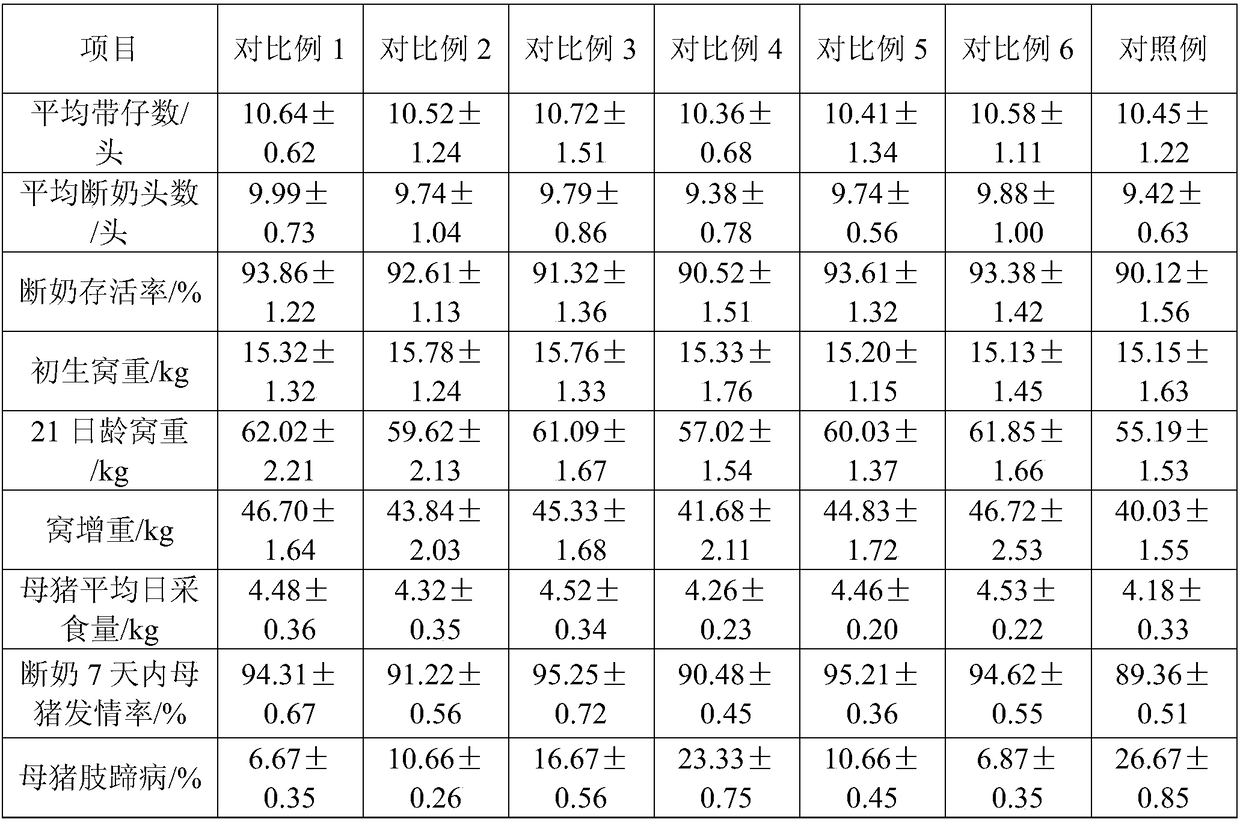

Examples

Embodiment 1

[0063] A nutritional supplement for lactating sows, comprising the following components in parts by weight:

[0064] 70 parts of puffed full-fat soybean powder (dry puffing, strong oil flavor, protein+fat=50%, crushed particle size 0.1mm), 25 parts of functional microcapsule-coated fat powder, and 5 parts of calcium supplement.

[0065] The preparation method of the expanded full-fat soybean powder is as follows: uniformly mix the antioxidant TBHQ (accounting for 5% of the mass of soybean) with the soybean, and then perform puffing and crushing treatment to obtain the expanded full-fat soybean powder; the expanded full-fat soybean The particle diameter of the powder was 0.05 mm.

[0066] The fat powder coated with functional microcapsules comprises the following components in parts by weight:

[0067] 29 parts of OPO structured fat, 7 parts of OPL structured fat, 8 parts of DHA, 2 parts of EPA, 1 part of myristic acid, 7 parts of lauric acid, 3 parts of sorbic acid, 3 parts o...

Embodiment 2

[0076] A nutritional supplement for lactating sows, comprising the following components in parts by weight:

[0077] 60 parts of puffed full-fat soybean powder (dry puffing, strong oil flavor, protein+fat=52%, crushed particle size 0.1mm), 30 parts of functional microcapsule-coated fat powder, and 10 parts of calcium supplement.

[0078]The preparation method of the expanded full-fat soybean powder is as follows: uniformly mixing the antioxidant BHT (accounting for 2% of the mass of the soybean) with the soybean and then performing expansion and crushing treatment to obtain the expanded full-fat soybean powder; the expanded full-fat soybean The particle size of the powder was 0.10 mm.

[0079] The fat powder coated with functional microcapsules comprises the following components in parts by weight:

[0080] 21 parts of OPO structured fat, 8 parts of OPL structured fat, 8 parts of DHA, 1 part of EPA, 1 part of myristic acid, 10 parts of lauric acid, 3 parts of sorbic acid, 3 p...

Embodiment 3

[0089] A nutritional supplement for lactating sows, comprising the following components in parts by weight:

[0090] 75 parts of puffed full-fat soybean powder (dry puffing, strong oil flavor, protein+fat=56%, crushed particle size 0.05mm), 20 parts of functional microcapsule-coated fat powder, 5 parts of calcium supplement.

[0091] The preparation method of the expanded full-fat soybean powder is as follows: uniformly mix the antioxidants BHT and TBHQ (the sum of the two accounts for 5% of the soybean mass percentage) with the soybean, and then perform expansion and crushing treatment to obtain the expanded full-fat soybean powder; The particle diameter of the expanded full-fat soybean flour is 0.15mm.

[0092] The fat powder coated with functional microcapsules comprises the following components in parts by weight:

[0093] 24 parts of OPO structural fat, 8 parts of OPL structural fat, 6 parts of DHA, 2 parts of EPA, 3 parts of myristic acid, 6 parts of lauric acid, 4 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com