Multi-element organic fertilizer and preparing method thereof

An organic fertilizer and multi-component technology, applied in the field of multi-component organic fertilizer and its preparation, can solve the problems of insufficient calcium supplementation and poor absorption performance, and achieve the effects of alleviating soil acidification, simple production process, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

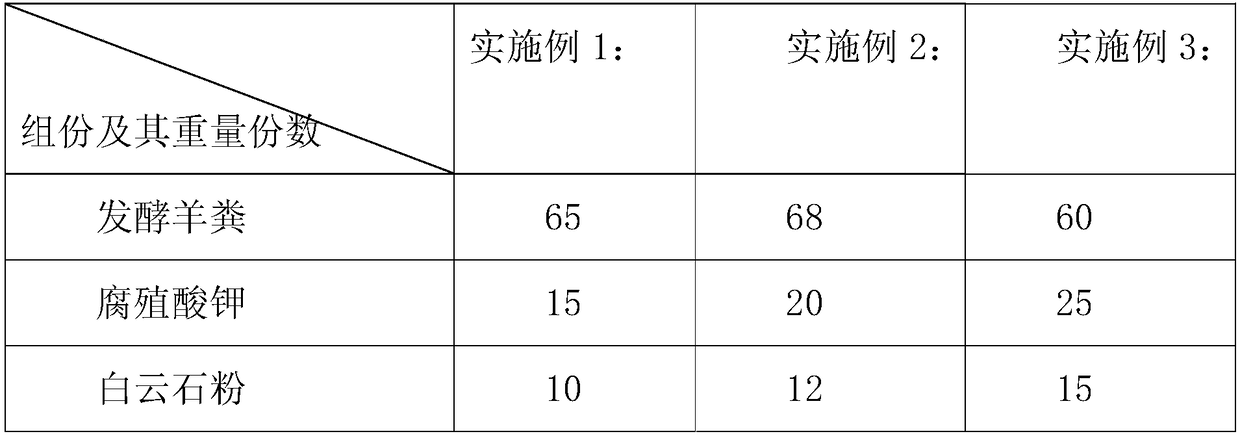

preparation example Construction

[0060] Further, the method for preparing fermented sheep manure comprises the following steps:

[0061] 1) Take 300-700 parts of sheep manure, 100-200 parts of fungus residue, 50-300 parts of wheat bran, add 1-10 parts of 20 billion Aspergillus niger and 0.5-5 parts of Bacillus subtilis, and mix thoroughly in a mixer for 1-20 minutes. spare.

[0062] 2) Add water to the well-mixed material to adjust it to about 20-50% by weight, and set it aside.

[0063] 3) Stack the above-mentioned spare mixed materials in the fermentation tank with a height of 1-2 meters, add a temperature controller, and cover with a plastic film for fermentation. When the temperature reaches 60 degrees Celsius, let the wind overturn to cool down;

[0064] 4) After cooling down for more than three times, letting the wind blow over, opening to dry and adjusting the moisture to 20-30% by weight, the fermented sheep manure is obtained.

[0065] The fermented sheep manure contains 40-50% of organic matter; 3...

Embodiment 4

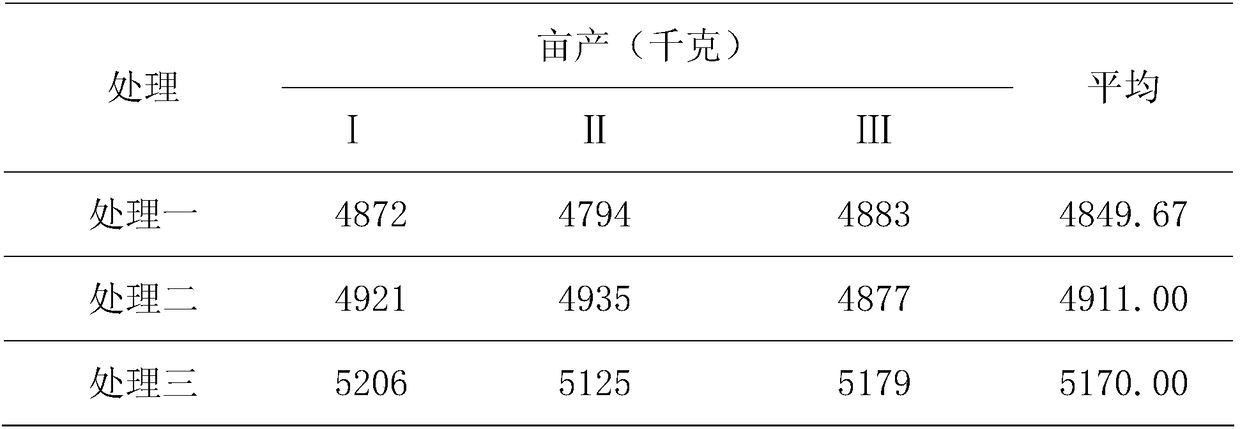

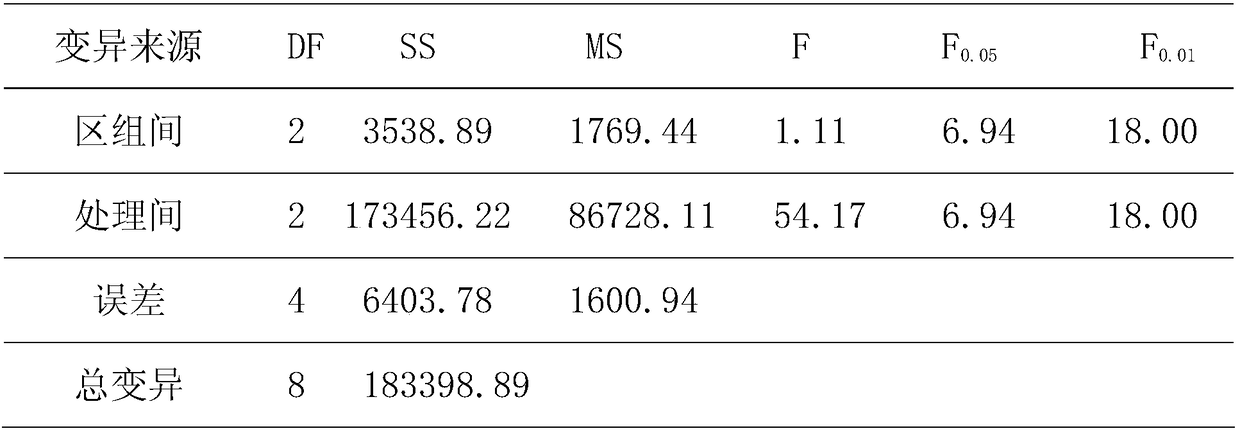

[0072] Embodiment 4: increase production, test effect analysis

[0073] The following field test result analysis report carried out by the soil and fertilizer station of Hebei Province has illustrated that the product produced by the present invention has a good effect.

[0074] "Field Test Report on Fertilizer Effect Identification of Multivariate Organic Fertilizers on Tomatoes"

[0075] In accordance with the requirements of the agricultural industry standard "Technical Regulations for Field Tests of Fertilizer Effect Identification", in order to verify the application effect of multi-component organic fertilizers in tomato production in Hebei, this test is specially arranged to provide a basis for popularization and application.

[0076] 1 Materials and methods

[0077] 1.1 Materials

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com