Stress whitening resistant PBT (Polybutylene Terephthalate) resin and preparation method thereof

A PBT resin and stress-resistant technology, which is applied in the field of stress-whitening-resistant PBT resin and its preparation, can solve the problems of poor stress cracking resistance, reduced elongation at break, and impact on product use, and achieve good bonding force, Easy processing and molding, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

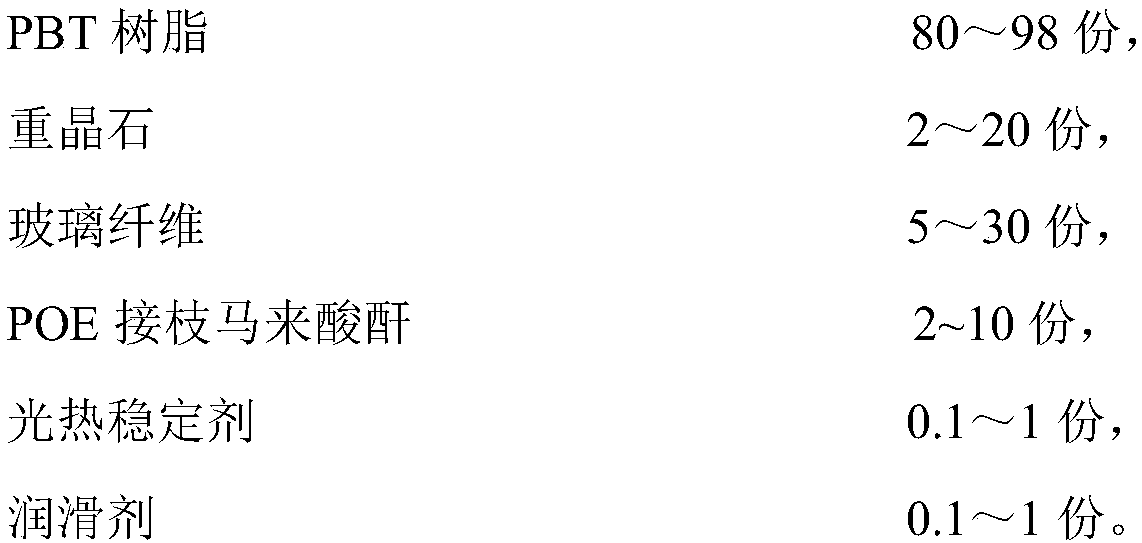

Method used

Image

Examples

Embodiment 1

[0037] (1) With 85 parts of PBT resin, 15 parts of barite (6000 orders), 5 parts of glass fibers, 2 parts of POE grafted maleic anhydride, 0.3 part of light and heat stabilizer (antioxidant 1076: antioxidant 168= 1:2, mass ratio) and 0.1 part of lubricant stearic acid amide (SR) are mixed evenly by high-speed stirring;

[0038] (2) sending the above-mentioned mixture into a twin-screw extruder to extrude and granulate to obtain PBT resin;

[0039] In the step (2), the screw temperature of the twin-screw extruder is 210° C., and the screw speed is 400 r / min.

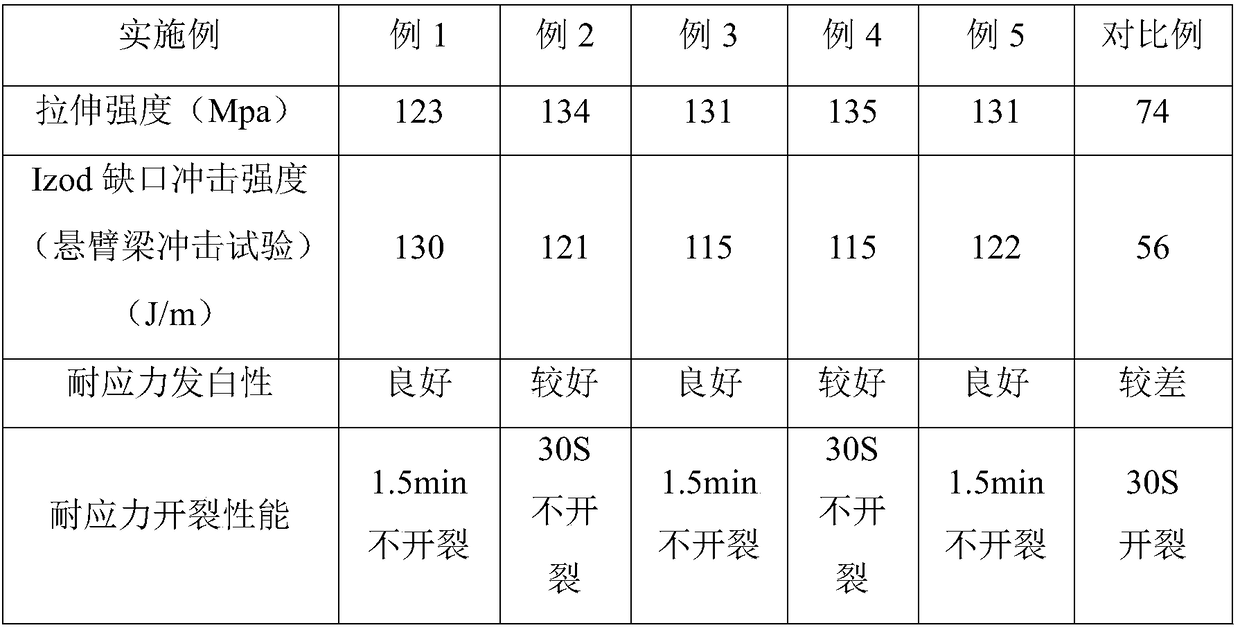

[0040] The prepared compound was injection-molded into a standard sample bar for testing according to the standard size, and the performance test results are shown in Table 2.

Embodiment 2

[0042] (1) 98 parts of PBT, 2 parts of barite (7000 mesh), 10 parts of glass fiber, 5 parts of POE grafted maleic anhydride, 0.6 parts of light and heat stabilizer (DLTP:DBTL=1:1, mass ratio) and 0.5 parts of lubricant silicone oil are mixed evenly by high-speed stirring;

[0043] (2) sending the above-mentioned mixture into a twin-screw extruder to extrude and granulate to obtain PBT resin;

[0044] In the step (2), the screw temperature of the twin-screw extruder is 230° C., and the screw speed is 500 r / min.

[0045] The prepared compound was injection-molded into a standard sample bar for testing according to the standard size, and the performance test results are shown in Table 2.

Embodiment 3

[0047] (1) 90 parts of PBT resin, 10 parts of barite (7000 mesh), 30 parts of glass fiber, 10 parts of POE grafted maleic anhydride, 0.1 part of light and heat stabilizer (DLTP: BHT = 2: 1, mass ratio ) and 1 part of lubricant EBS are mixed evenly by high-speed stirring;

[0048] (2) sending the above-mentioned mixture into a twin-screw extruder to extrude and granulate to obtain PBT resin;

[0049] In the step (2), the screw temperature of the twin-screw extruder is 200° C., and the screw speed is 300 r / min.

[0050] The prepared compound was injection-molded into a standard sample bar for testing according to the standard size, and the performance test results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com