Leather mould-proof material preparation method

A kind of mildew-proof and leather-proof technology, which is applied in the field of preparation of leather mold-proof materials, can solve the problems of affecting the service life of leather products, uneven distribution of components, poor adhesion ability, etc., and achieve excellent sterilization effect, small harm and low biological toxicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

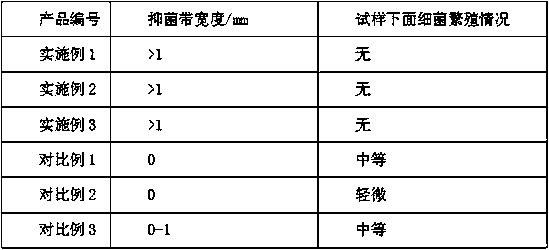

Examples

Embodiment 1

[0018] In the reaction kettle, add ethanol 100Kg, carboxymethyl chitosan 15Kg, tert-butyldimethylsilyl trifluoromethanesulfonate 0.3Kg, p-trifluoromethoxyphenyl isocyanate 0.5Kg, 1Kg cetyl alcohol Polyether-23, 2-[ethyl[(heptadecafluorooctyl)sulfonyl]amino]ethanol polyglycol ether 0.2Kg, neodymium triacrylate 0.2Kg, stir at 250rpm at a temperature of 75°C After 3 hours, the leather antibacterial agent product is obtained.

Embodiment 2

[0020] In the reaction kettle, add ethanol 100Kg, carboxymethyl chitosan 10Kg, tert-butyldimethylsilyl trifluoromethanesulfonate 0.1Kg, p-trifluoromethoxyphenyl isocyanate 0.2Kg, 0.5Kg spermaceti Alcohol-23, 2-[ethyl[(heptadecafluorooctyl)sulfonyl]amino]ethanol polyglycol ether 0.1Kg, neodymium triacrylate 0.1Kg, at 70°C, at a speed of 200rpm Stir for 2 hours to obtain the leather antibacterial agent product.

Embodiment 3

[0022] In the reaction kettle, add ethanol 100Kg, carboxymethyl chitosan 20Kg, tert-butyldimethylsilyl trifluoromethanesulfonate 0.5Kg, p-trifluoromethoxyphenyl isocyanate 0.8Kg, 1.5Kg spermaceti Alcohol-23, 2-[ethyl[(heptadecafluorooctyl)sulfonyl]amino]ethanol polyglycol ether 0.3Kg, neodymium triacrylate 0.3Kg, at a temperature of 80°C, at a speed of 300rpm Stir for 4 hours to obtain the leather antibacterial agent product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com