Recycling method and device of salt-containing coking desulfurization waste liquid

A technology of salt-containing waste liquid, coking desulfurization, applied in chemical instruments and methods, filtration treatment, separation methods, etc., can solve problems such as corrosion of metal flue equipment environment, neglect of exhaust gas, pollution, etc., to reduce equipment corrosion damage and cost. Inexpensive, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

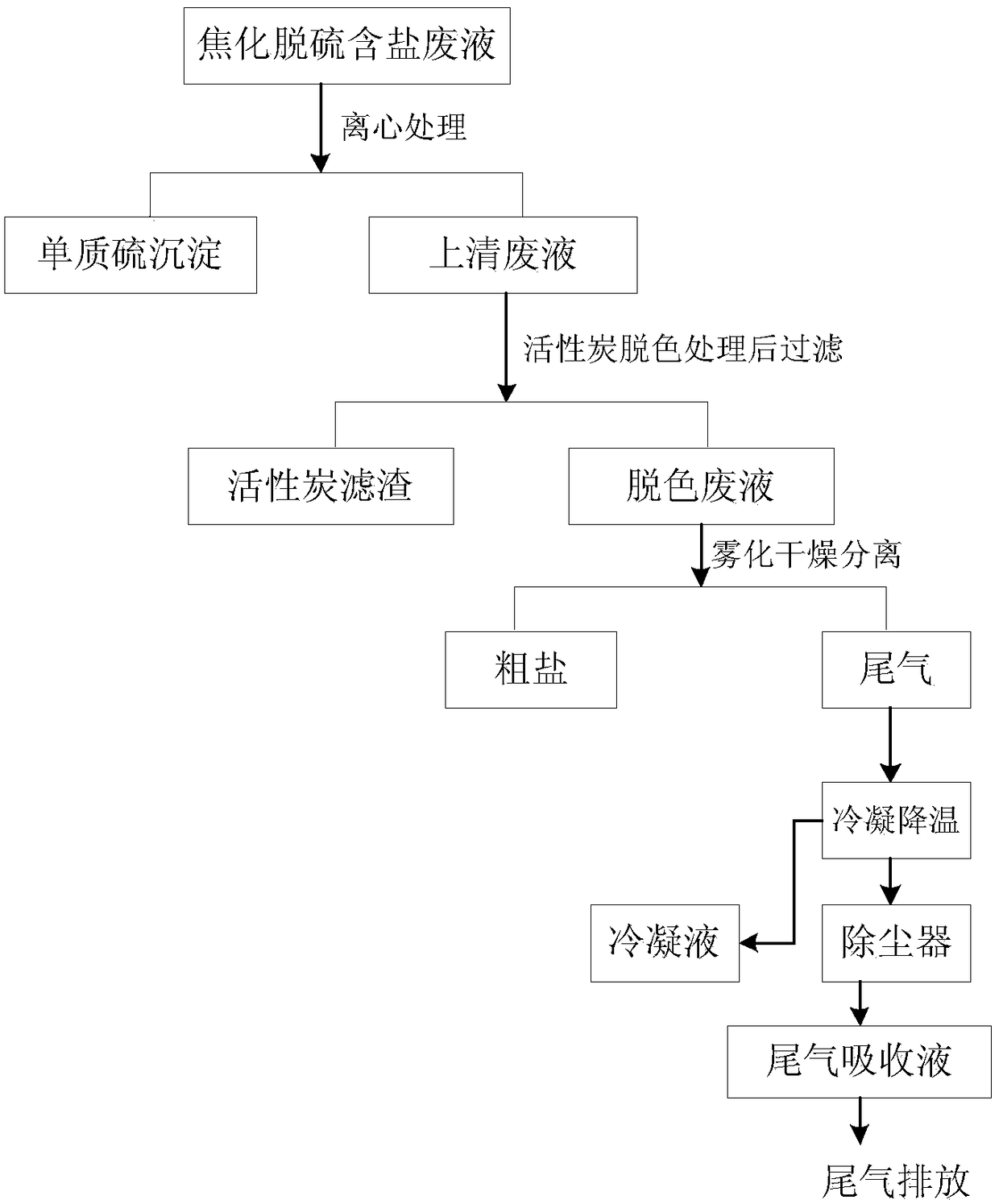

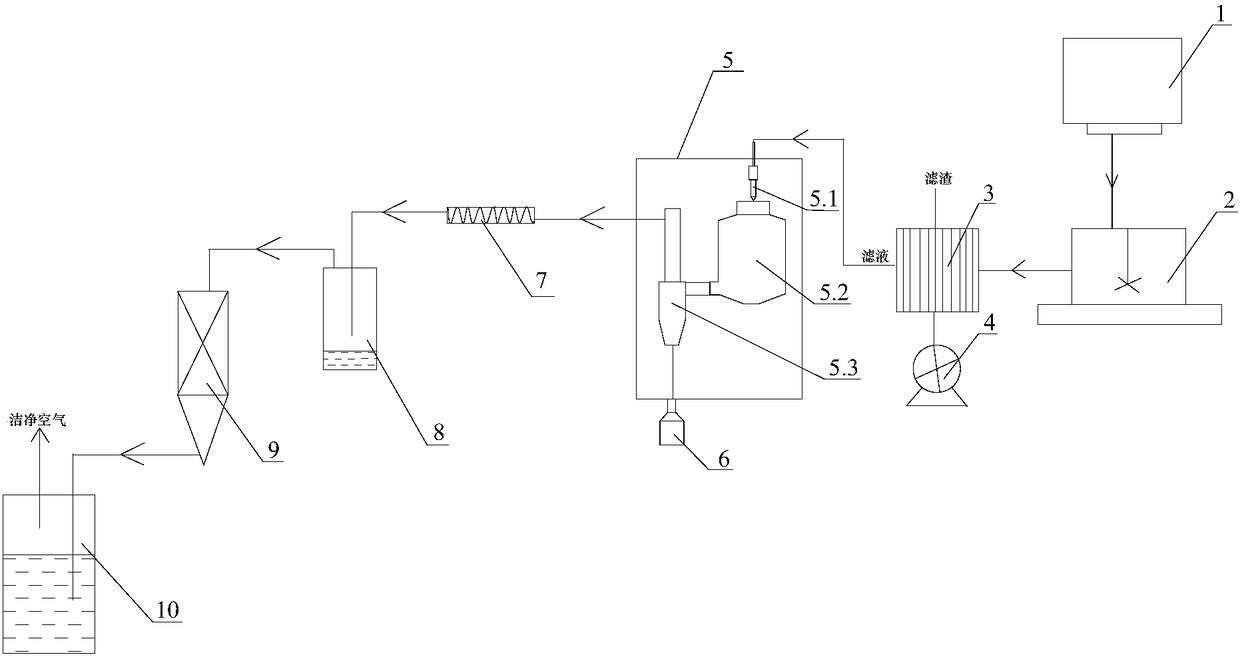

[0030] The coking desulfurization salt-containing waste liquid in Example 1 comes from Wuhan Iron and Steel No. 1 steelmaking desulfurization waste liquid. The desulfurization section uses sodium carbonate as the alkali source for desulfurization. The main components of the coking desulfurization salt-containing waste liquid are sodium thiocyanate and thiosulfuric acid. Sodium, suspended sulfur. combine figure 1 and figure 2 As shown, the resource treatment method of coking desulfurization salt-containing waste liquid in this embodiment includes the following steps:

[0031] 1) Removal of elemental sulfur: Coking desulfurization salt-containing waste liquid is centrifuged in a centrifuge at a centrifugal rate of 4000 rpm for 3 minutes to obtain a supernatant waste liquid, which is separated and removed from the elemental sulfur precipitate;

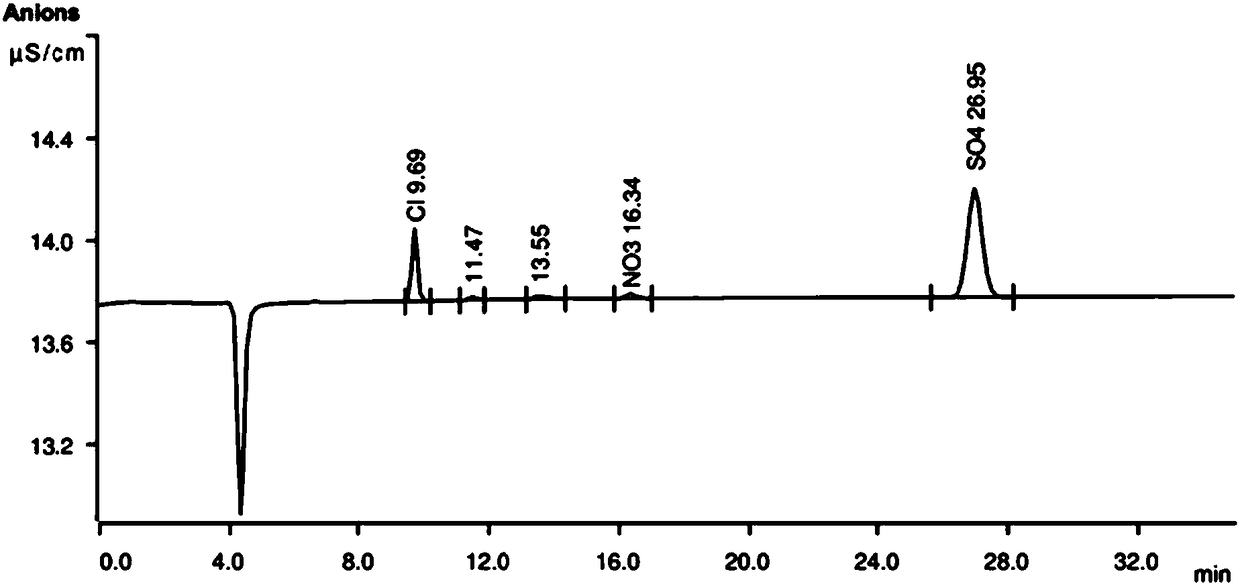

[0032] 2) Decolorization: Add activated carbon to the supernatant waste liquid for decolorization treatment, then filter the activate...

Embodiment 2

[0041] The coking desulfurization salt-containing waste liquid in Example 2 comes from Wuhan Iron and Steel No. 1 steelmaking desulfurization waste liquid. The desulfurization section uses sodium carbonate as the alkali source for desulfurization. The main components of the coking desulfurization salt-containing waste liquid are sodium thiocyanate and thiosulfuric acid. Sodium, suspended sulfur. to combine figure 1 and figure 2 As shown, the resource treatment method of coking desulfurization salt-containing waste liquid in this embodiment includes the following steps:

[0042] 1) Removal of elemental sulfur: Coking desulfurization salt-containing waste liquid is centrifuged in a centrifuge at a centrifugal rate of 6000 rpm for 4 minutes to obtain a supernatant waste liquid, which is separated and removed from the elemental sulfur precipitate;

[0043] 2) Decolorization: Add activated carbon to the supernatant waste liquid for decolorization treatment, and then filter the a...

Embodiment 3

[0051] The coking desulfurization salt-containing waste liquid in Example 3 comes from the desulfurization waste liquid of the coking plant of Hubei Xinye Steel Co., Ltd. The desulfurization section uses ammonia as the alkali source for desulfurization. The main components of the coking desulfurization salt-containing waste liquid are ammonium thiocyanate, Ammonium Thiosulfate, Suspended Sulfur. to combine figure 1 and figure 2 As shown, the resource treatment method of coking desulfurization salt-containing waste liquid in this embodiment includes the following steps:

[0052] 1) Removal of elemental sulfur: Coking desulfurization salt-containing waste liquid is centrifuged in a centrifuge at a centrifugation rate of 10,000 rpm and a centrifugation time of 5 minutes to obtain a supernatant waste liquid, which is separated and removed from the elemental sulfur precipitate;

[0053] 2) Decolorization: Add activated carbon to the supernatant waste liquid for decolorization tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com