Preparation method of building concrete

A technology for concrete and construction, applied in the field of concrete preparation for construction, can solve the problems of difficult thermal insulation effect of concrete, poor concrete strength, corrosion resistance and thermal insulation effect, etc., and achieves good thermal insulation function and high mixing uniformity. , to achieve the effect of energy saving and consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

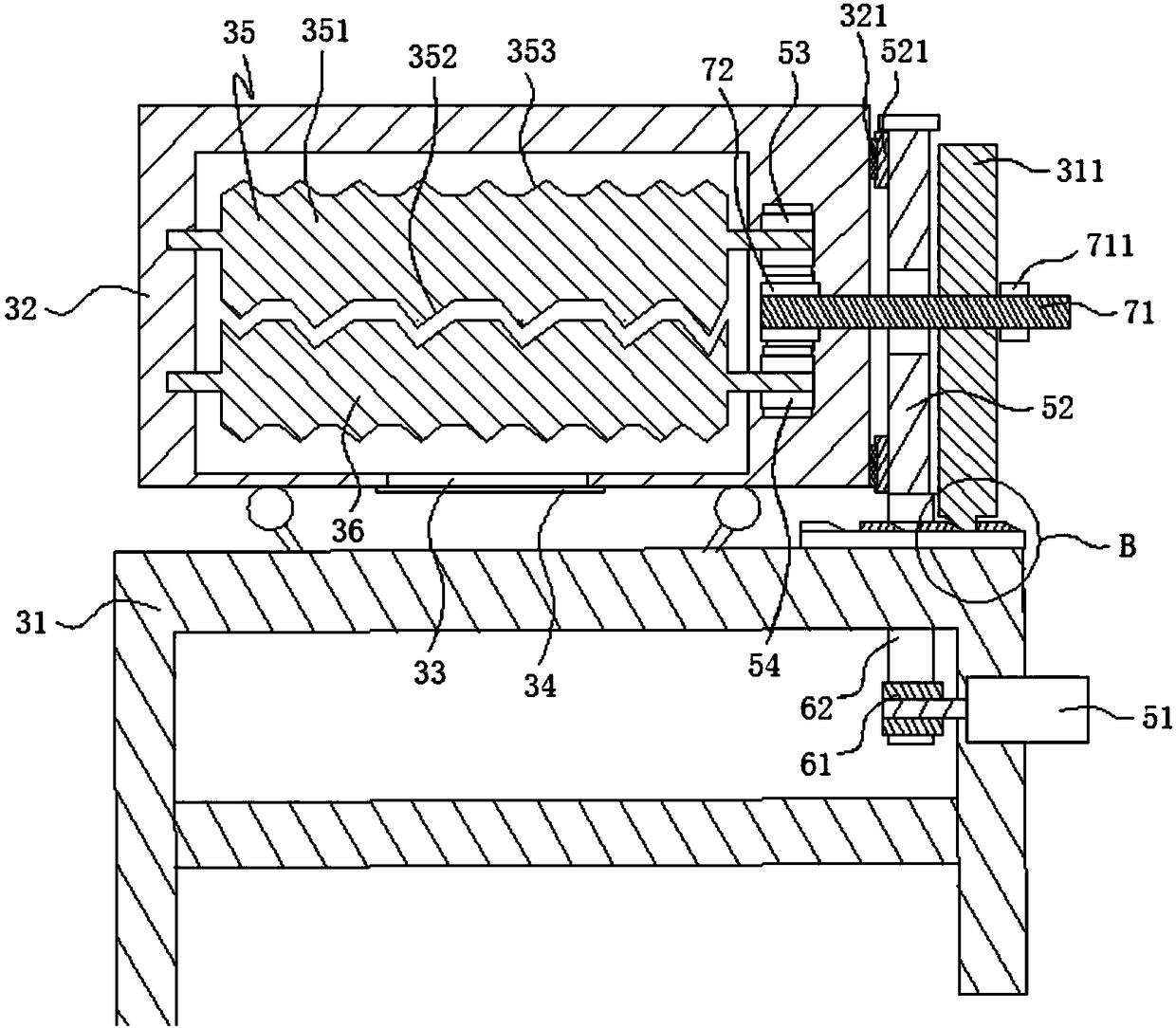

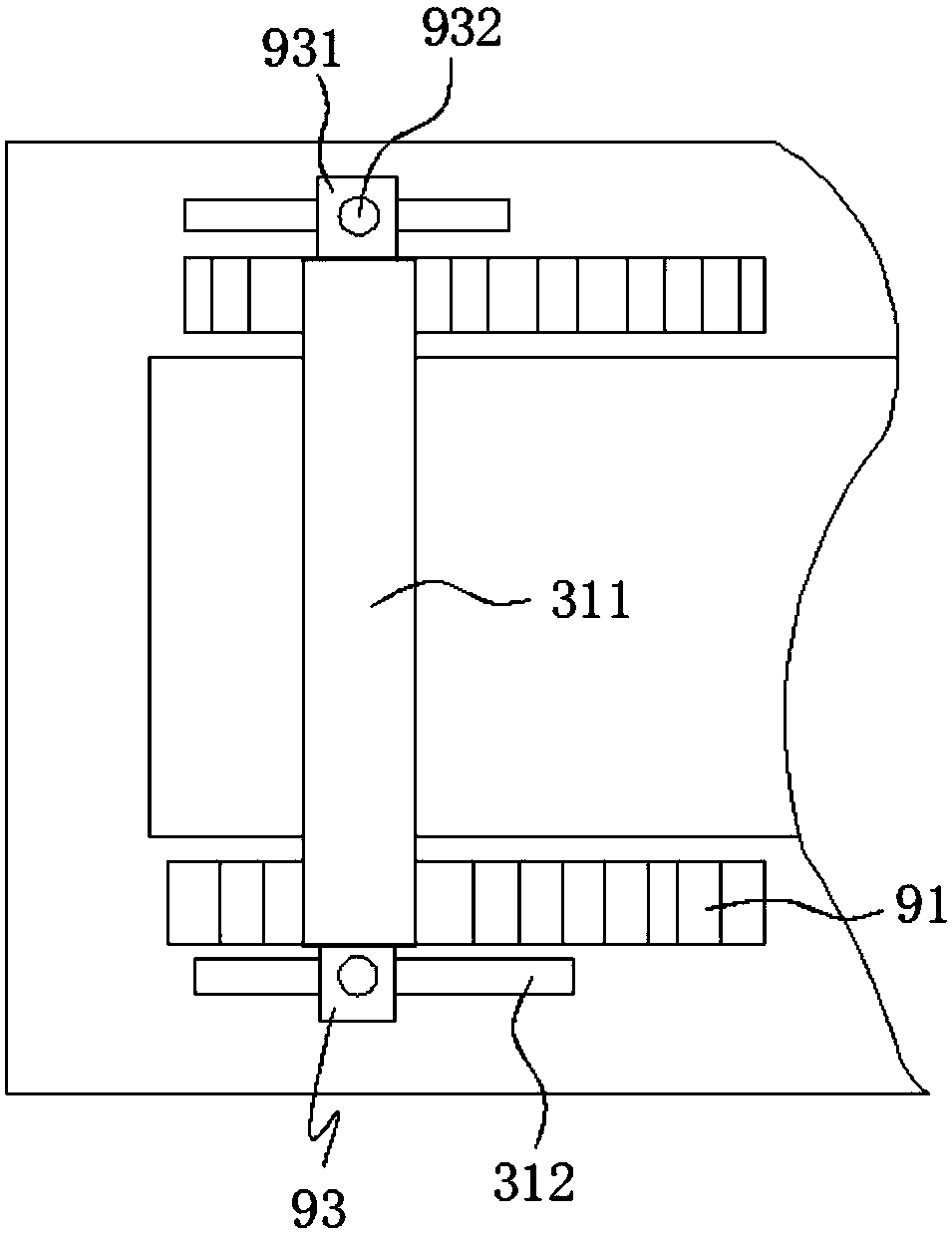

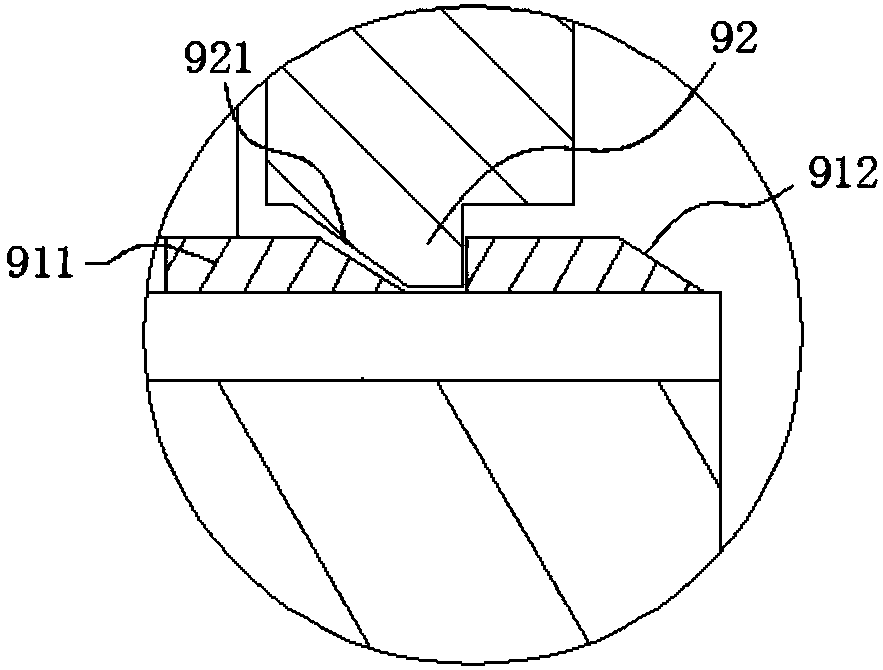

[0030]A method for preparing concrete for construction, comprising the following steps: (1) raw material preparation: taking cement, gravel, sand, sludge, coal gangue, sepiolite powder, imitation steel fiber, expansion agent, water, and water reducing agent; Among them, sand and gravel are obtained by crushing construction waste materials through a crushing device. After the crushing device is crushed once, 60% of the material is taken out as sand and gravel; after that, the remaining 40% of the sand and gravel are continuously crushed to obtain sand; specifically, the The particle diameter of the sand and gravel is 8mm, and the particle diameter of the sand is 2mm; the sludge is obtained by scraping mud at the bottom of the sedimentation tank by a mud scraper; the water reducing agent is composed of the following components by weight: polymer 40 parts of carboxylic acid mother liquor, 6 parts of slump-preserving agent, 2.5 parts of triethanolamine, 4 parts of acetone; sepiolit...

Embodiment 2

[0039] A method for preparing concrete for construction, comprising the following steps: (1) raw material preparation: taking cement, gravel, sand, sludge, coal gangue, sepiolite powder, imitation steel fiber, expansion agent, water, and water reducing agent; Among them, sand and gravel are obtained by crushing construction waste materials through a crushing device. After the crushing device is crushed once, 60% of the material is taken out as sand and gravel; after that, the remaining 40% of the sand and gravel are continuously crushed to obtain sand; specifically, the The particle diameter of the sand and gravel is 10mm, and the particle diameter of the sand is 3mm; the sludge is obtained by scraping mud at the bottom of the sedimentation tank by a mud scraper; the water reducer is composed of the following components by weight: polymer 45 parts of carboxylic acid mother liquor, 10 parts of slump-preserving agent, 3.5 parts of triethanolamine, 6 parts of acetone; sepiolite po...

Embodiment 3

[0042] A method for preparing concrete for construction, comprising the following steps: (1) raw material preparation: taking cement, gravel, sand, sludge, coal gangue, sepiolite powder, imitation steel fiber, expansion agent, water, and water reducing agent; Among them, sand and gravel are obtained by crushing construction waste materials through a crushing device. After the crushing device is crushed once, 60% of the material is taken out as sand and gravel; after that, the remaining 40% of the sand and gravel are continuously crushed to obtain sand; specifically, the The particle diameter of the sand and gravel is 10mm, and the particle diameter of the sand is 2mm; the sludge is obtained by scraping mud at the bottom of the sedimentation tank by a mud scraper; the water reducer is composed of the following components by weight: polymer 40 parts of carboxylic acid mother liquor, 10 parts of slump-preserving agent, 2.5 parts of triethanolamine, 4 parts of acetone; sepiolite po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap