Preparation method of carbon nanotube composite material

A composite material and carbon nanotube technology, which is applied in the field of preparing carbon nanotube composite materials by vacuum filtration method, can solve the problems of affecting the mechanical properties of composite materials, inability to infiltrate resin uniformly, and low resin content, etc., so as to shorten the preparation cycle and shorten the Immersion time, improve the effect of infiltration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Preparation method of high-strength carbon nanotube composite material

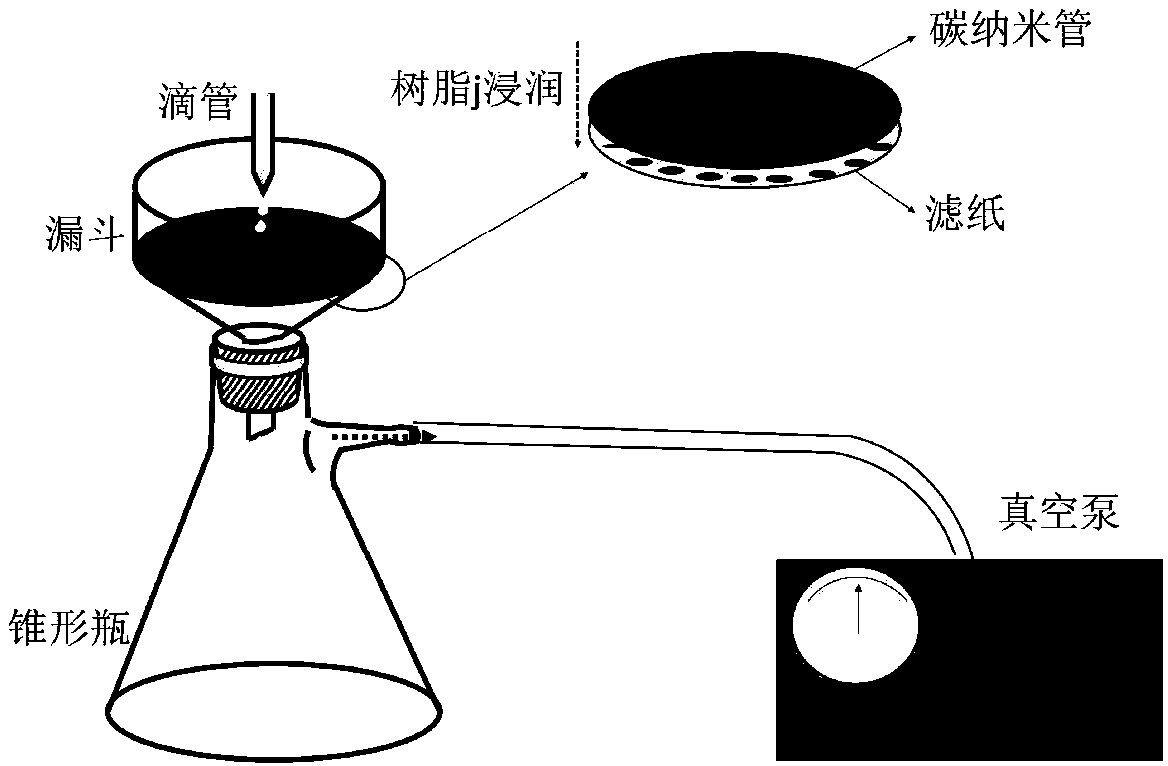

[0031] Assemble the vertical suction filtration equipment: connect a ceramic funnel with a diameter of 70 mm to the conical flask through a cork, connect the conical flask to the vacuum pump with a gas tube, seal the top of the funnel, and test the airtightness of the equipment to ensure that there is no air leakage.

[0032] The resin matrix of the composite material used in this example is epoxy resin (Guangzhou Hengyue Chemical Co., Ltd., brand: E-51), and the carbon nanotube film is a carbon nanotube film prepared by floating catalytic chemical vapor deposition.

[0033] The preparation method of carbon nanotube composite material in the present embodiment is as follows:

[0034] (1) Clean and wet the carbon nanotube film with acetone

[0035] Cut the carbon nanotube film into a circle with a diameter of 60 mm with a blade, and clean the surface impurities with acetone.

[0036] (2)...

Embodiment 2

[0044] Example 2 Preparation method of carbon nanotube film composite tension sensor

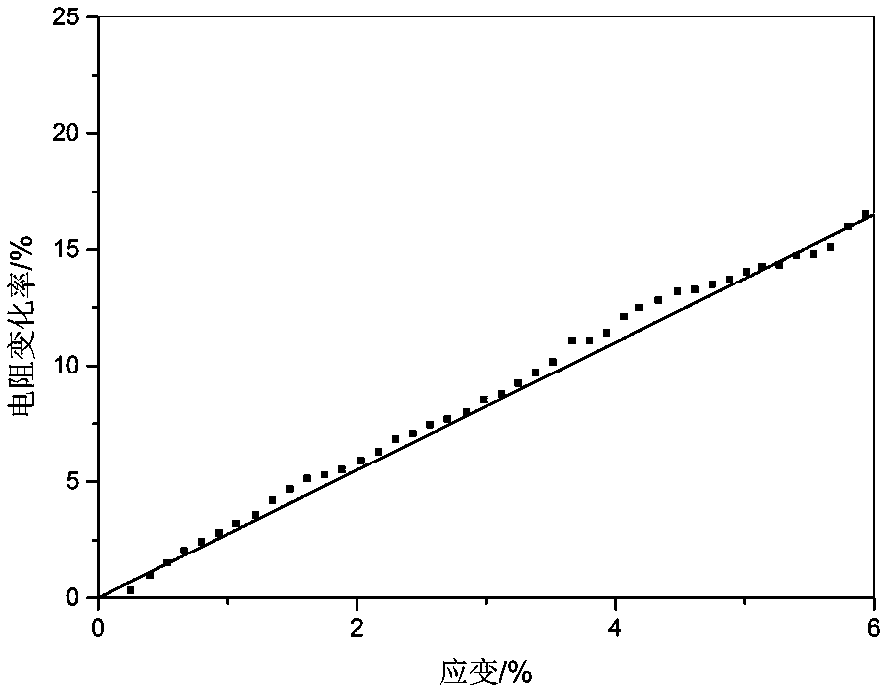

[0045] In this example, a composite material with high carbon nanotube content is prepared by vertical suction filtration method, and the composite material and the stressed structural member are fixed together. Under the action of tension, the resistance of the composite material increases linearly with the increase of strain, thus A carbon nanotube film composite tension sensor was prepared.

[0046]In this embodiment, polymethyl methacrylate (Mitsubishi, brand: 460) was selected as the resin matrix, and a carbon nanotube film prepared by floating catalytic chemical vapor deposition was used as the reinforcement.

[0047] The preparation method of carbon nanotube composite material in the present embodiment is as follows:

[0048] (1) Use acetone to clean and wet the carbon nanotube film:

[0049] Cut the carbon nanotube film into a circle with a diameter of 60 mm with a blade, and clean...

Embodiment 3

[0060] Example 3 Preparation method of high temperature resistant carbon nanotube composite material

[0061] The composite material resin matrix is replaced by aviation resin such as bismaleimide resin (Suzhou Pinyu Optoelectronics Technology Co., Ltd., brand: PY8006T), which can benefit from the flame retardancy of carbon nanotubes and the high temperature resistance of BMI. Preparation of high temperature resistant carbon nanotube composites.

[0062] The preparation method of carbon nanotube composite material in the present embodiment is as follows:

[0063] (1) Use acetone to clean and wet the carbon nanotube film:

[0064] Cut the carbon nanotube film into a circle with a diameter of 60 mm with a blade, and clean the surface impurities with acetone.

[0065] (2) Configure resin solution

[0066] Bismaleimide resin (BMI) was diluted with acetone to 10 g of diluted resin mixture A with a viscosity of 2.5 mpa.s and 10 g of diluted resin mixture B with a viscosity of 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com