High weather-resistant galvanized coating for lamp post and preparation method thereof

A light pole and coating technology, applied in the field of coatings, can solve the problems of affecting the health of workers, polluting the working environment, poor protection performance, etc., and achieve the effects of shortening the drying time, good protection, and low heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

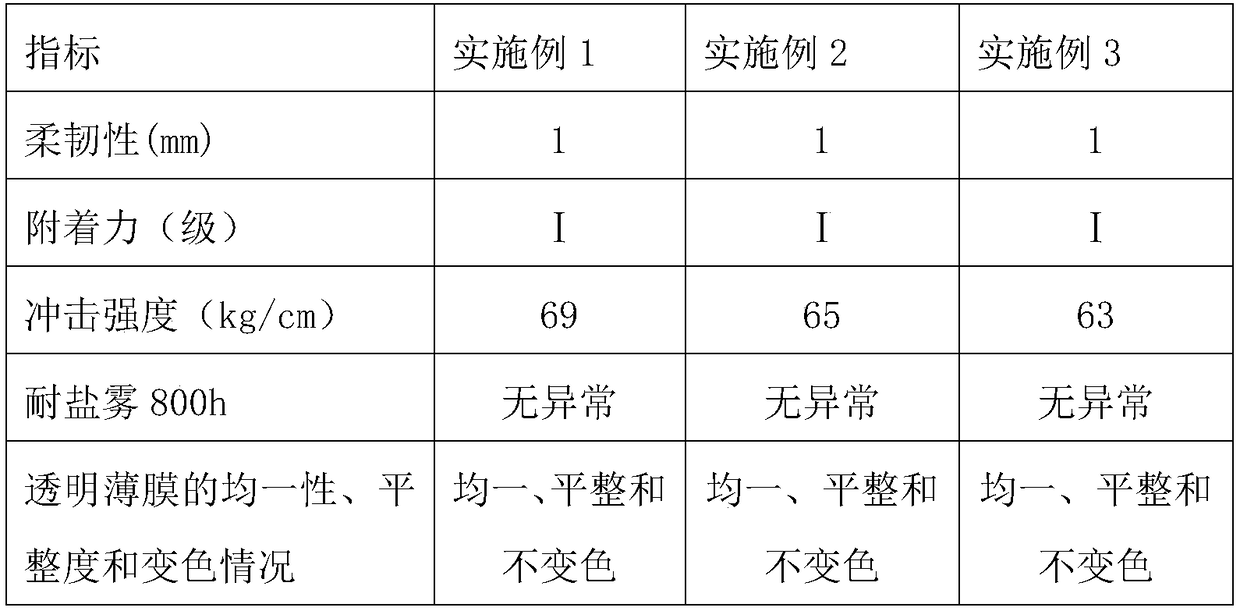

Examples

Embodiment 1

[0035] A high weather-resistant galvanized paint for light poles, including the following raw materials: 15kg of acrylic resin, 3kg of attapulgite, 5kg of diatomite, 4kg of light calcium carbonate, 0.9kg of toughening agent, and 0.5kg of defoaming agent , Drying agent 1kg, leveling agent 0.4kg, stearic acid 0.15kg, hindered amine antioxidant 0.4kg, anti-skinning agent 5kg, coupling agent 0.4kg, zinc powder 84kg and deionized water 33kg;

[0036] Zinc powder is a mixture of micron-sized zinc powder and nano-sized zinc powder. The content in the mixture is 10% to 45%;

[0037] Zinc powder is zinc powder modified by fluorosilane coupling agent, fluorosilane coupling agent is 1H,1H,2H,2H-perfluorodecyltriethoxysilane, 1H,1H,2H,2H-perfluoro Mixture of Octyltriethoxysilane, Tridecafluorooctyltrimethoxysilane, Triethoxy-1H,1H,2H,2H-Tridecafluoro-N-octylsilane.

[0038] The toughening agent is a styrene-butadiene thermoplastic elastomer.

[0039] The defoamer is a mixture of emulsi...

Embodiment 2

[0051] A high weather-resistant galvanized paint for light poles, including the following raw materials: 5kg of acrylic resin, 2kg of attapulgite, 4kg of diatomite, 3kg of light calcium carbonate, 0.6kg of toughening agent, and 0.3kg of defoamer , 0.7kg of drying agent, 0.3kg of leveling agent, 0.1kg of stearic acid, 0.3kg of hindered amine antioxidant, 4kg of anti-skinning agent, 0.2kg of coupling agent, 75kg of zinc powder and 1kg of deionized water;

[0052] Zinc powder is a mixture of micron-sized zinc powder and nano-sized zinc powder. The content in the mixture is 10% to 45%;

[0053] Zinc powder is zinc powder modified by fluorosilane coupling agent, fluorosilane coupling agent is 1H,1H,2H,2H-perfluorodecyltriethoxysilane, 1H,1H,2H,2H-perfluoro Octyltriethoxysilane, tridecafluorooctyltrimethoxysilane, triethoxy-1H,1H,2H,2H-tridecafluoro-N-octylsilane or a mixture of two or more.

[0054] The toughening agent is methyl methacrylate-butadiene-styrene terpolymer.

[005...

Embodiment 3

[0066] A high weather resistance galvanized paint for light poles, including the following raw materials: 25kg of acrylic resin, 4kg of attapulgite, 6kg of diatomite, 5kg of light calcium carbonate, 1.2kg of toughening agent, and 0.7kg of defoamer , Drying agent 1.3kg, leveling agent 0.5kg, stearic acid 0.2kg, hindered amine antioxidant 0.5kg, anti-skinning agent 6kg, coupling agent 0.6kg, zinc powder 93kg and deionized water 65kg;

[0067] Zinc powder is a mixture of micron-sized zinc powder and nano-sized zinc powder. The content in the mixture is 10% to 45%;

[0068] Zinc powder is zinc powder modified by fluorosilane coupling agent, fluorosilane coupling agent is 1H,1H,2H,2H-perfluorodecyltriethoxysilane, 1H,1H,2H,2H-perfluoro Octyltriethoxysilane, tridecafluorooctyltrimethoxysilane, triethoxy-1H,1H,2H,2H-tridecafluoro-N-octylsilane or a mixture of two or more.

[0069] The toughening agent is acrylonitrile-butadiene-styrene copolymer.

[0070] The defoamer is polyoxyet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com