Three-dimensional interval-filling structure heat-collecting evaporation fabric and preparation, using method and usage

A heat-collecting, three-dimensional technology, applied in the direction of fabrics, multi-strand fabrics, textiles, and papermaking, can solve the problems of high equipment cost, low desalination efficiency, and slow desalination process, so as to improve water evaporation efficiency, short process flow, The effect of fast evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Heat collecting and evaporating fabric with three-dimensional space filling structure based on cotton fiber

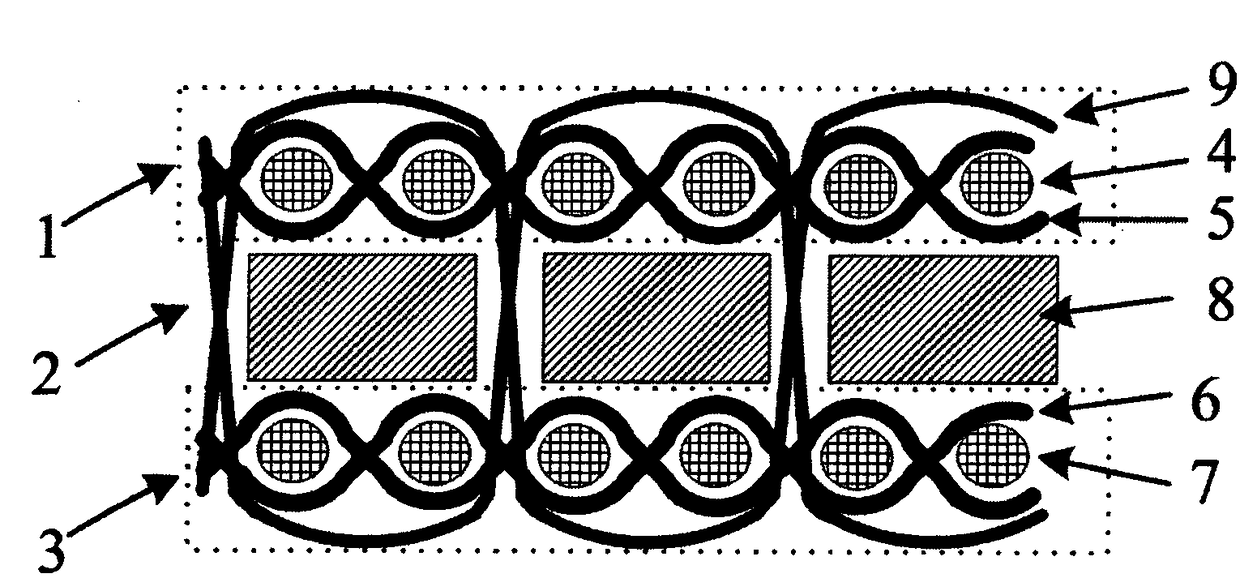

[0031] Combine figure 1 , Select 20 cotton fibers as the water-absorbent layer warp yarn 6 and water-absorbent layer weft yarn 7 to weave the water-absorbent layer 3; select 30 ramie fibers as the spacer yarn 9; select a length of 10 cm, a width of 0.4 cm, a height of 0.5 cm, and a hole diameter of 10-20 microns The closed-cell foamed sponge is used as the floating embedding material 8 of the floating heat insulation layer 2; 15 black cotton fibers are selected for air deformation as the heat collection evaporation layer warp yarn 4 and the heat collection evaporation layer weft yarn 5 to weave the heat collection evaporation layer 1. Set fabric width 10 cm, warp and weft density: 5 yarns / cm; spacer yarn density: 2.5 yarns / cm.

[0032] Weaving process: In the first step, the weft insertion device is activated to introduce the upper and lower layers of weft yarn; the...

Embodiment 2

[0035] Heat collecting and evaporating fabric with three-dimensional space filling structure based on polyester fiber

[0036] Use 15 cotton fibers as warp and weft yarns to weave the water absorption layer; select 20 ramie fibers as spacer yarns; select closed-cell foam sponges with a length of 10 cm, a width of 0.5 cm, a height of 0.5 cm, and a pore size of 10-20 microns as the floating embedding material ; Select 1500tex hydrophilic modified polyester bulked yarn as the warp and weft yarn weaving heat collection evaporation layer. Set fabric width 10 cm, warp and weft density: 4 yarns / cm; spacer yarn density: 2 yarns / cm.

[0037] Weaving process: In the first step, the weft insertion device is activated to introduce the upper and lower layers of weft yarn; the second step is the single-group heald frame movement to drive the upper and lower warps to weave synchronously to realize the weaving of the upper and lower layers, namely the water absorption layer and the evaporation lay...

Embodiment 3

[0040] Heat collection and evaporation fabric with three-dimensional interval filling structure based on regenerated cellulose fiber

[0041] Use 600tex regenerated cellulose filament as warp and weft weaving water absorption layer, select black 600tex regenerated cellulose filament bulked yarn as warp and weft weaving heat collection evaporation layer; select polyethylene hollow with closed ends of 0.5 cm in diameter and 80% porosity The tube is used as the floating embedding material, and 30 ramie fibers are selected as the spacer yarn. Set fabric width 10 cm, warp and weft density: 10 yarns / cm; spacer yarn density: 2 yarns / cm.

[0042] Weaving process: In the first step, the weft insertion device is activated to introduce the upper and lower layers of weft yarn; the second step is the single-group heald frame movement to drive the upper and lower warps to weave synchronously to realize the weaving of the upper and lower layers, namely the water absorption layer and the evaporati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com