Method for dyeing acrylic fabric with berberis poiretii schneid plant dye

A plant dye and three-needle technology, which is applied to the field of dyeing acrylic fabrics with three-needle plant dyes, can solve the problems of difficulty in controlling the dyeing color, uneven color of the fabric, poor fastness and easy color fading, etc., and achieves soft color. Natural, high color fastness, non-fading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

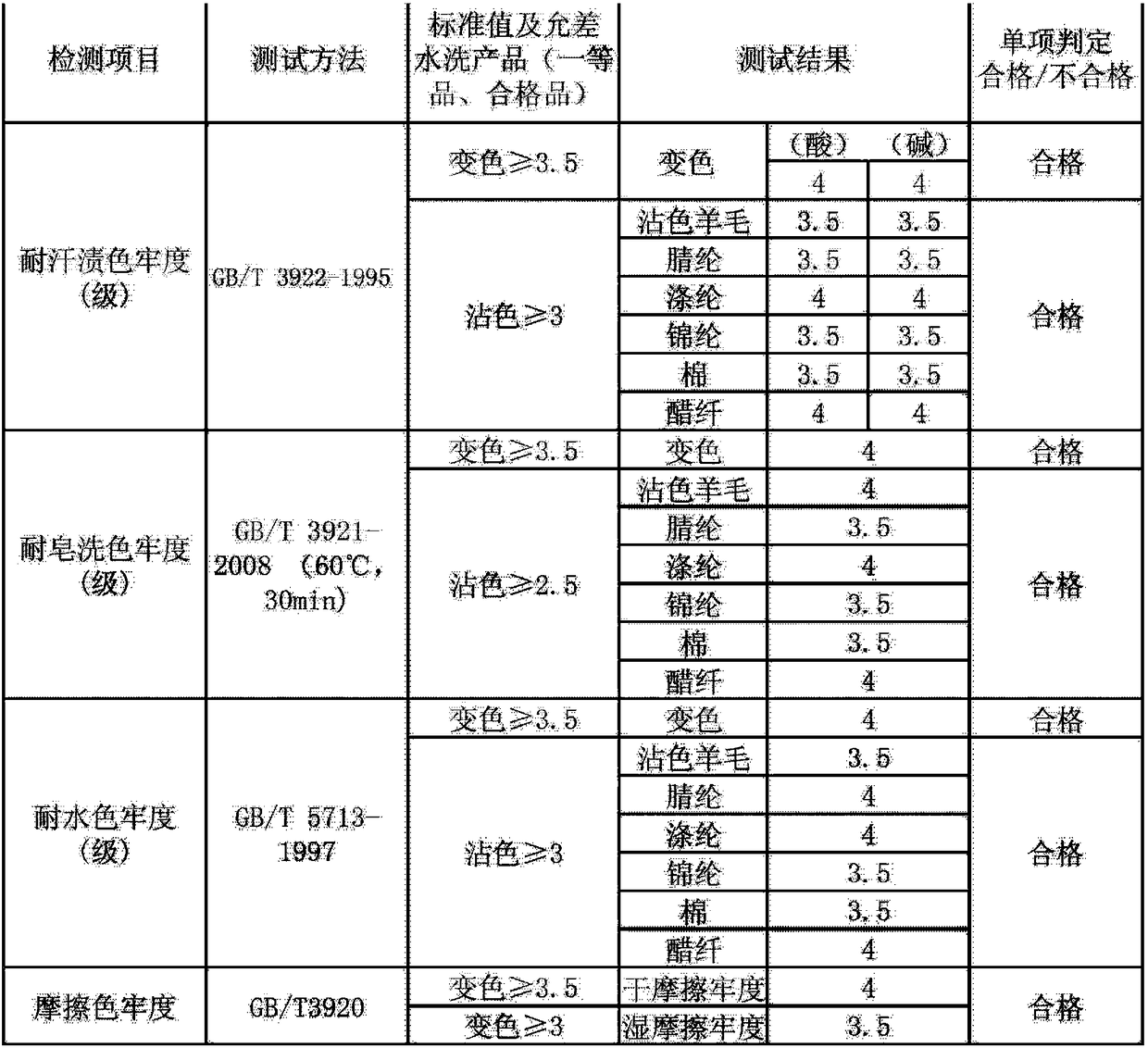

Embodiment 1

[0032] Dyeing embodiment 1: concrete operation steps are:

[0033] (1) Extraction of three needles: after finely crushing the fresh leaves of three needles, immerse in a mixed solvent prepared by 95v% ethanol and acetone according to the volume ratio of 1:1, after cold immersion for 5 hours, filter, and heat the filtrate to reflux The method is further extracted and concentrated, and then the concentrated extract is dried to obtain three needle plant dyes; wherein, the weight ratio of the three needle fresh leaves to the mixed solvent is 1:20;

[0034] (2) Dyeing solution preparation: get the prepared three needle plant dyes, prepare the dyeing solution with a dye concentration of 35% (owf) at a bath ratio of 1:30, then add ammonium acetate retarder in the said dyeing solution, Described ammonium acetate consumption is controlled at 30.0g / l;

[0035] (3) Pretreatment of acrylic fiber fabric: after acrylic fiber fabric is put into warm water and soaked for 20min, obtain the ac...

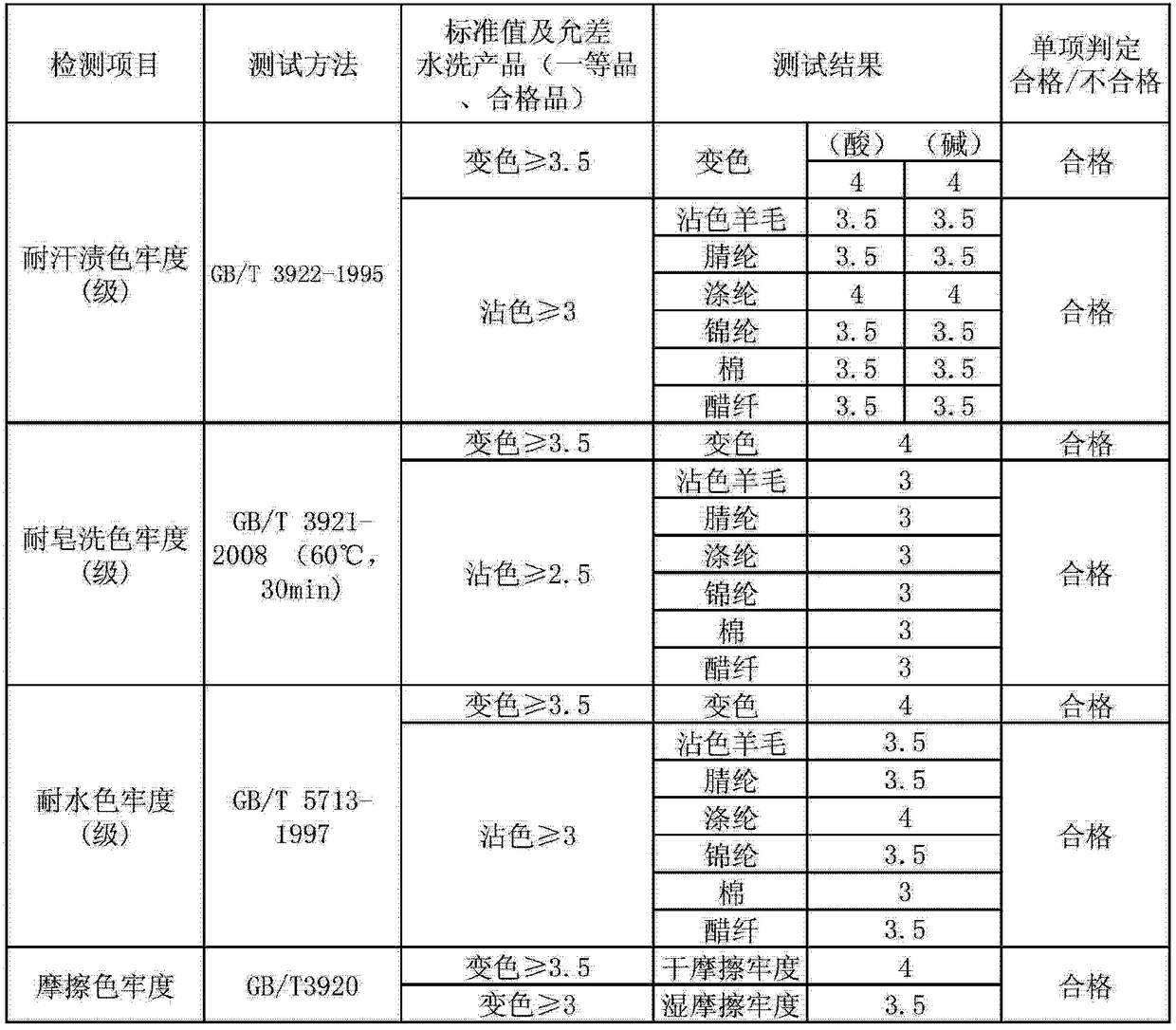

Embodiment 2

[0041] Dyeing embodiment 2: the specific operation steps are as follows:

[0042](1) Extraction of three needles: Finely crush the fresh leaves of three needles, immerse in a mixed solvent prepared by 95v% ethanol and acetone according to the volume ratio of 1:1, soak for 2 hours after cold soaking, filter, and heat the filtrate to reflux The method is further extracted and concentrated, and then the concentrated extract is dried to obtain three needle plant dyes; wherein, the weight ratio of the three needle fresh leaves to the mixed solvent is 1:30;

[0043] (2) Dyeing liquid preparation: get the three needle plant dyes prepared, be mixed with the dyeing liquid that dye concentration is 10% (owf) by bath ratio 1:100, then add ammonium acetate retarder in described dyeing liquid, Described ammonium acetate consumption is controlled at 1.0g / l;

[0044] (3) Pretreatment of acrylic fiber fabric: after acrylic fiber fabric is put into warm water and soaked for 20min, obtain the ...

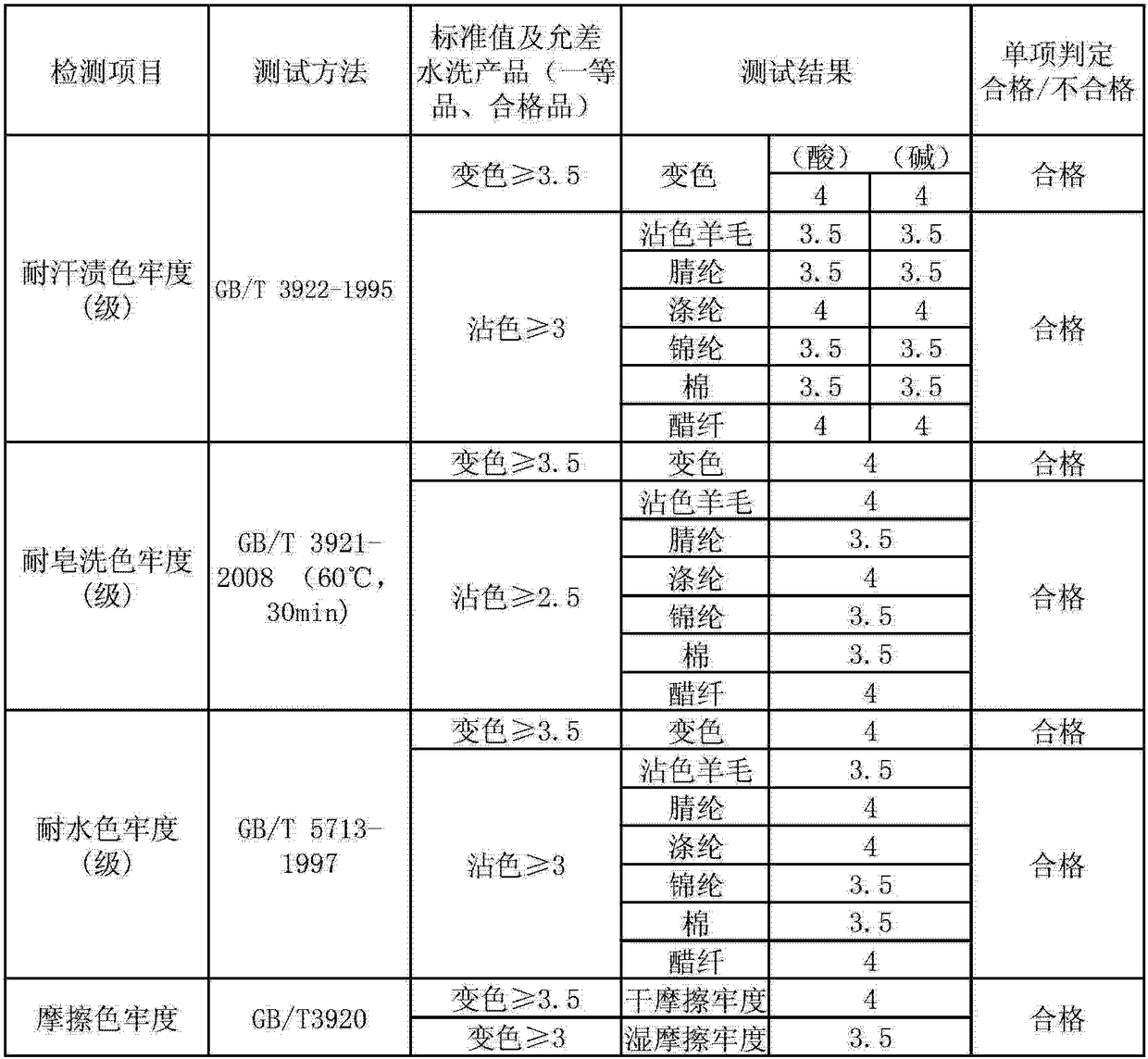

Embodiment 3

[0050] Dyeing embodiment 3: the specific operation steps are as follows:

[0051] (1) Extraction of three needles: finely crush the fresh leaves of three needles, immerse in a mixed solvent prepared by 95v% ethanol and acetone according to the volume ratio of 1:1, after cold soaking for 3 hours, filter, and heat the filtrate to reflux The method is further extracted and concentrated, and then the concentrated extract is dried to obtain three needle plant dyes; wherein, the weight ratio of the three needle fresh leaves to the mixed solvent is 1:25;

[0052] (2) Dyeing solution preparation: take the prepared three needle plant dyes, prepare a dyeing solution with a dye concentration of 10-35% (owf) at a bath ratio of 1:50, and then add ammonium acetate to slow dyeing in the dyeing solution agent, the ammonium acetate consumption is controlled at 20.0g / l;

[0053] (3) Pretreatment of acrylic fiber fabric: after acrylic fiber fabric is put into warm water and soaked for 20min, ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com