Method for preparing high-structure-dimension and high-reinforcing white carbon black and white carbon black obtained by same

A white carbon black and mixed liquid technology, applied in the field of white carbon black, can solve the problems such as the decline of rubber tear strength, wear resistance and other properties, affecting the service life and safety of tires, and low dispersion of white carbon black, etc. To achieve the effect of reducing the surface tension of the solution, promoting the formation of the solid phase, and the preparation method is simple and feasible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

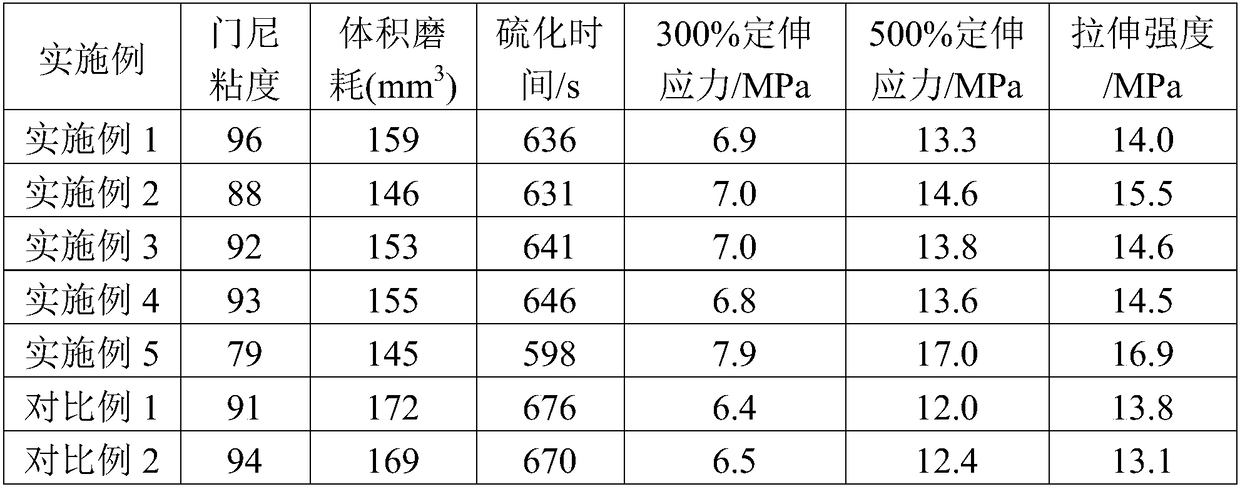

Examples

Embodiment 1

[0031] The preparation method of the white carbon black that the present embodiment provides is as follows:

[0032] (1) Add sodium dodecylbenzenesulfonate to SiO 2 Concentration is 1.34mol / L in the water glass solution, under the stirring rate of 250rpm, heat up to 85 ℃, wherein, the addition amount of sodium dodecylbenzenesulfonate is SiO 2 The theoretical yield is 2.47wt%, and the modulus of water glass is 3.3.

[0033] (2) Sodium sulfate is added in the mixed solution that step (1) obtains, stirring reaction, utilize sulfuric acid solution to adjust pH in reaction process, wherein, the addition of sodium sulfate is SiO 2 1.56 wt% of theoretical yield.

[0034] (3) Stop the reaction when the pH value of the reaction solution is 5.0, and age for 120 minutes to obtain a white carbon black mixture.

[0035] (4) Washing the white carbon black mixed solution obtained in step (3), centrifuging and filtering, drying in an oven at 105° C., controlling the water content of the wh...

Embodiment 2

[0037] The preparation method of the white carbon black that the present embodiment provides is as follows:

[0038] (1) Add sodium dodecylbenzenesulfonate to SiO 2 Concentration is 1.5mol / L water glass solution, under the stirring rate of 200rpm, heat up to 80 ℃, wherein, the addition amount of sodium dodecylbenzene sulfonate is SiO 2 2wt% of theoretical output, the modulus of water glass is 3.

[0039] (2) Sodium sulfate is added in the mixed solution that step (1) obtains, stirring reaction, utilize sulfuric acid solution to regulate pH in reaction process, wherein, the addition of sodium sulfate is SiO 2 3 wt% of theoretical yield.

[0040] (3) Stop the reaction when the pH value of the reaction solution is 5.5, and age for 50 minutes to obtain a white carbon black mixture.

[0041] (4) Washing the white carbon black mixed solution obtained in step (3), centrifuging and filtering, drying in an oven at 100° C., controlling the water content of the white carbon black to 8...

Embodiment 3

[0043] The preparation method of the white carbon black that the present embodiment provides is as follows:

[0044] (1) Add sodium dodecylbenzenesulfonate to SiO 2 Concentration is 1mol / L water glass solution, under the stirring rate of 450rpm, heat up to 90 ℃, wherein, the addition amount of sodium dodecylbenzene sulfonate is SiO 2 3wt% of theoretical output, the modulus of water glass is 4.

[0045] (2) Sodium sulfate is added in the mixed solution that step (1) obtains, stirring reaction, utilize sulfuric acid solution to regulate pH in reaction process, wherein, the addition of sodium sulfate is SiO 2 0.1 wt% of theoretical yield.

[0046] (3) Stop the reaction when the pH value of the reaction solution is 4.0, and age for 70 minutes to obtain a white carbon black mixture.

[0047](4) Washing the white carbon black mixed solution obtained in step (3), centrifuging and filtering, drying in an oven at 115° C., controlling the water content of the white carbon black to 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| oil absorption value | aaaaa | aaaaa |

| oil absorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com