Method of preparing high-purity polypeptide or analogue thereof

An analog and high-purity technology, which is applied in the field of preparing high-purity polypeptides or their analogs, can solve the problems of the mobile phase system for preparation, the method is not described in detail, the polarity of AMG416 is large, and the purification is difficult, and the effective preparation and purification can be achieved. , Good prospects for industrial application, and the effect of improving purification yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Chromatographic conditions: Agilent 1260 preparative system, YMC 5μm C18 filler prepacked 20*250mm preparative column. Prepare an aqueous ammonium phosphate solution with a concentration of 50mM, use phosphoric acid to adjust pH=3.0, use it as phase A, methanol as phase B, the volume ratio of phase A to phase B is 97:3, the elution method is isocratic elution, the flow rate is 10ml / min.

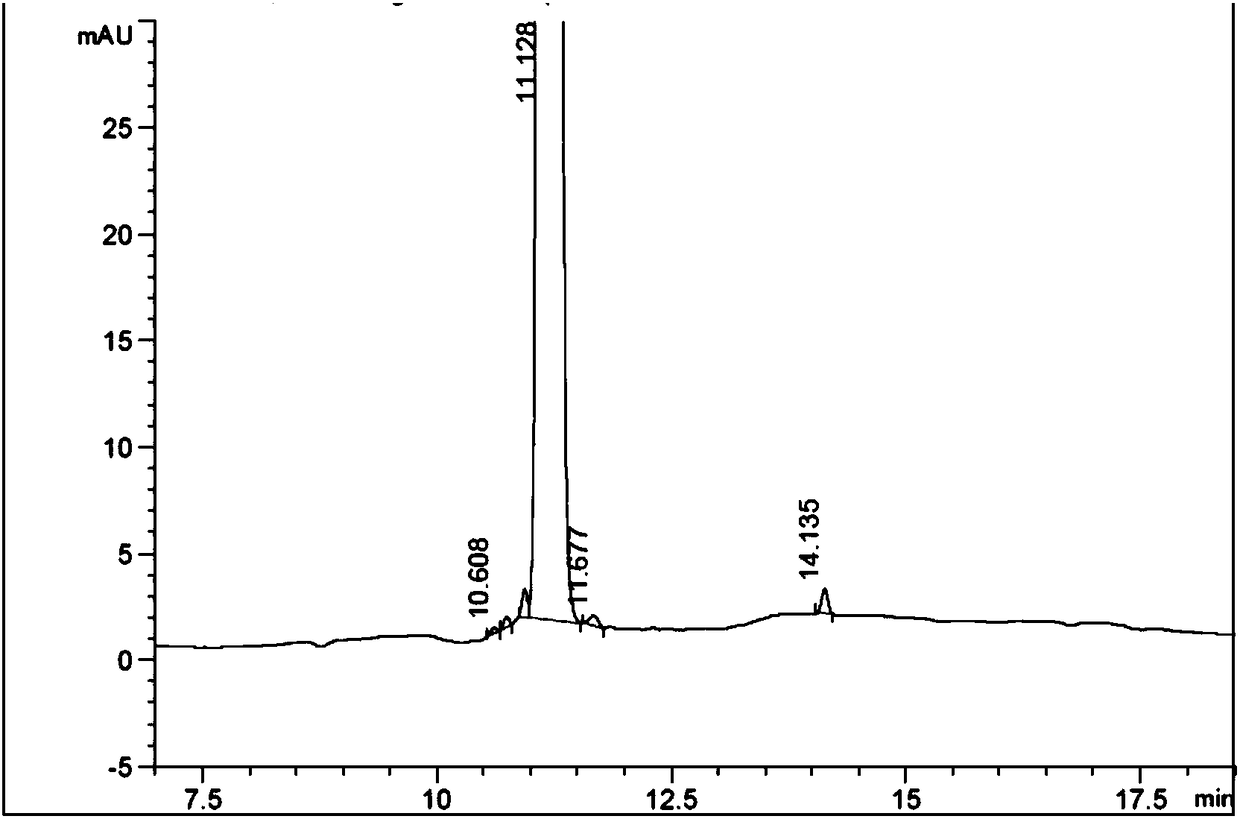

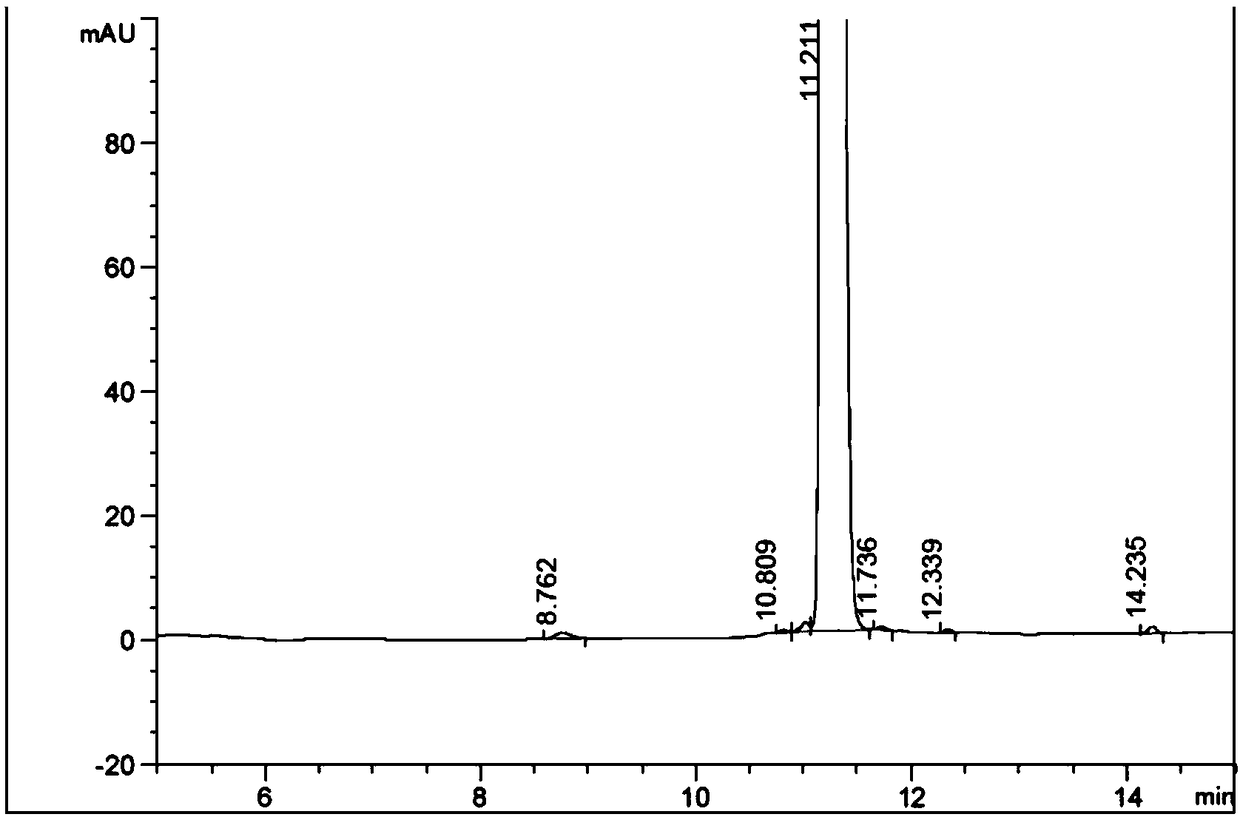

[0061] Take 50 mg of AMG416 crude product (purity of the crude product is 69%) dissolved in 1 ml of purified water and filter the sample. The peak of purpose is collected, and the peak fraction of purpose is combined to obtain AMG416 solution, and its RP-HPLC purity is 99.75% (such as figure 1 shown); the solution is converted to hydrochloride by chemical method after using an ion exchange packing chromatographic column or lyophilized, and lyophilized to obtain 31.5mg AMG416 hydrochloride refined peptide, and its RP-HPLC purity is 99.52% (such as figure 2 shown). It can be seen fr...

Embodiment 2

[0067] step one:

[0068] Chromatographic conditions: Agilent 1260 preparative system, 20*250mm preparative column prepacked with Daiso 10μm C18 filler. Prepare an aqueous solution of ammonium formate with a concentration of 30mM, use formic acid to adjust the pH to 3.5, use as phase A, methanol as phase B, the volume ratio of phase A to phase B is 95:5, the elution method is isocratic elution, the flow rate is 10ml / min.

[0069] Take 50 mg of AMG416 crude product (purity of the crude product is 69%) dissolved in 1 ml of purified water and filter the sample. Collect the target peak, combine the target fractions and freeze-dry the solution to obtain the refined product of AMG416.

[0070] Step two:

[0071] The Agilent 1260 preparation system was used, and the 20*250mm preparation column prepacked with Suzhou Nanowell 10μm C18 filler was used. Prepare 0.1% TFA aqueous solution as phase A and methanol as phase B. Phase B was increased from 5% to 20% within 25 minutes at a ...

Embodiment 3

[0074] Chromatographic conditions: Hanbang DAC80 preparation system, Hanbang SP 10μm C18 packing DAC 80*250mm preparative column. Prepare an aqueous ammonium phosphate solution with a concentration of 50mM, use phosphoric acid to adjust the pH to 3.0, use it as phase A, methanol as phase B, the volume ratio of phase A to phase B is 95:5, the elution method is isocratic elution, and the flow rate is 160ml / min.

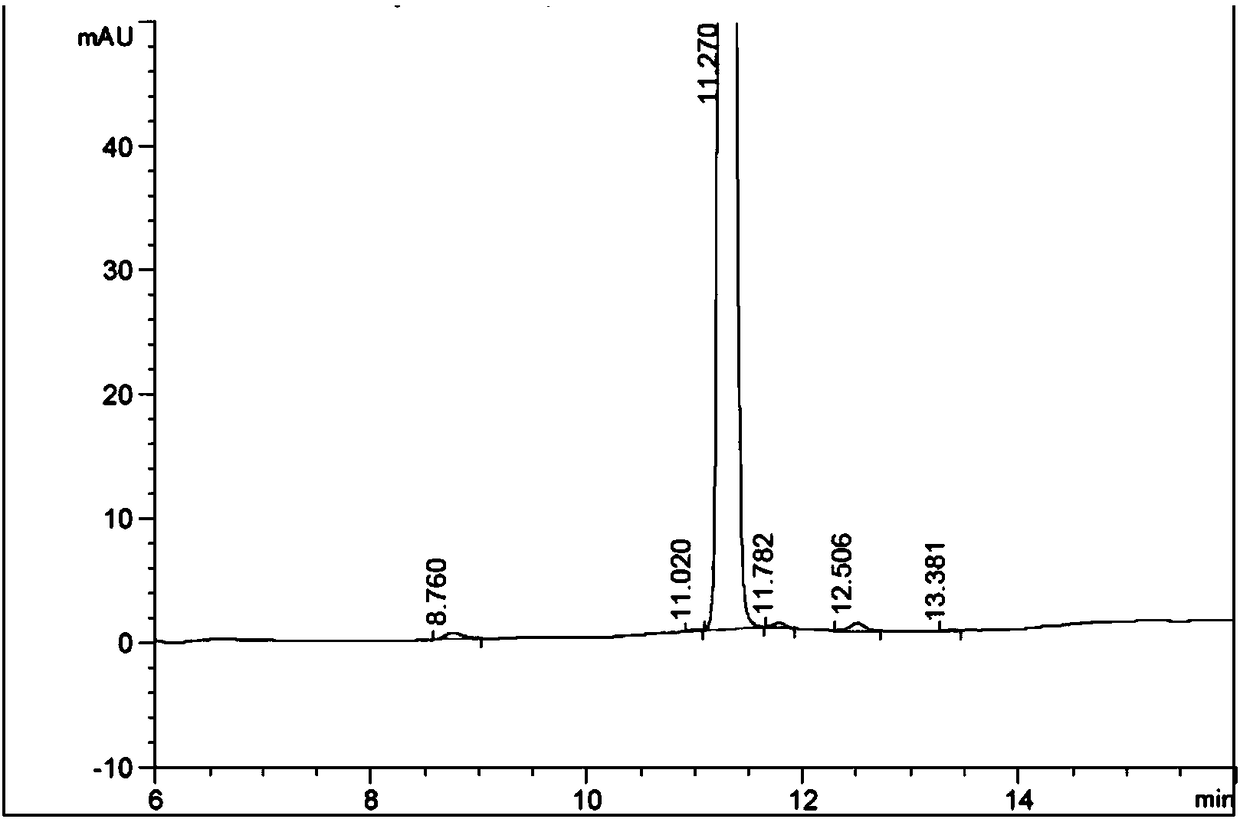

[0075] Take 810 mg of AMG416 crude product (purity of the crude product is 69%) and dissolve it in 20 ml of purified water, use a small amount of acetic acid / ammonia water to adjust the pH to 6.80, and filter the sample. Collect the purpose peak, and the purpose peak cuts are combined to obtain the AMG416 solution, and its RP-HPLC purity is 99.39% (such as image 3 Shown), the solution is converted to acetate, and freeze-dried to obtain the AMG416 acetate essence peptide of 572mg. Calculation shows that the weight yield of the method is 70.6%.

[0076] Table 3: Chro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com