Polyurethane structural adhesive having long working life and increasing rapidly in strength and preparation method thereof

A polyurethane and pot life technology, which is applied in the field of two-component polyurethane structural adhesives, can solve the problems of strong irritating odor and short operation time (generally no more than 30 minutes), so as to improve the hardness and strength after curing, and prolong the operation time , the effect of high boiling point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

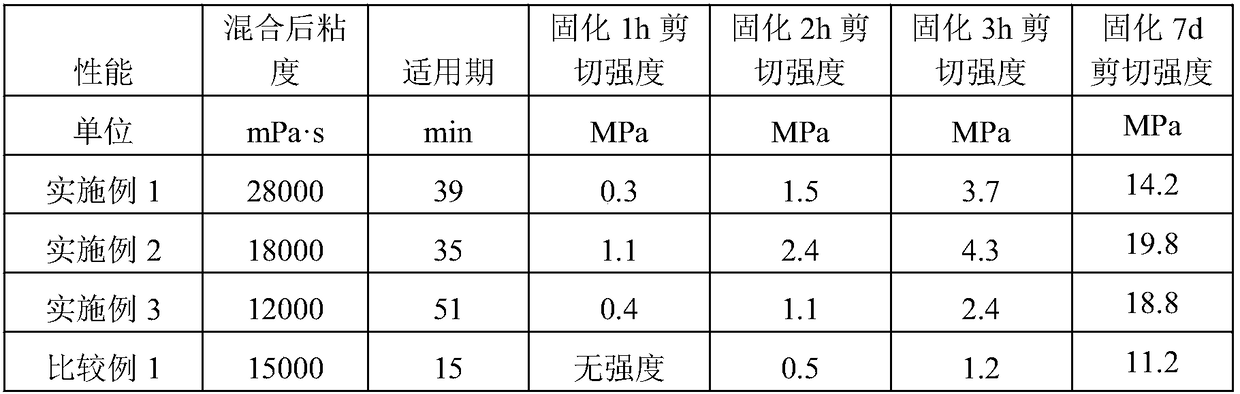

Examples

preparation example Construction

[0044] The present invention also provides a method for preparing any of the above-mentioned polyurethane structural adhesives with long pot life and fast strength increase, comprising the following steps:

[0045] Prepare component A and component B, the sequence of preparing component A and component B is not limited;

[0046] The preparation method of component A is: add castor oil polyol, bisphenol A modified polyether triol, environment-friendly organic solvent, polyether hexaol into the reaction kettle, heat to 100°C-120°C, and vacuum Stir and dehydrate under the state for 1-2 hours, then lower the temperature to 60°C, add it to the planetary stirring mixer, then add the viscosity-increasing agent, viscosity-reducing agent, retarder and delayed catalyst, and stir for 30 minutes under vacuum. Then add inorganic fillers and molecular sieve dewatering agents, and stir for 2 hours under vacuum to obtain component A;

[0047] Component B is an isocyanate curing agent compris...

Embodiment 1

[0052] In terms of mass percentage, add 35% castor oil polyol, 10% bisphenol A modified polyether triol, 5% environmentally friendly organic solvent, and 5% polyether hexaol to the reactor and heat to 100°C-120°C , and stirred and dehydrated under vacuum for 1 to 2 hours, then cooled to 60 ° C, added to the planetary mixer, and then added 0.5% viscosity-increasing additive, 1.1% viscosity reducing agent, 0.3% polymerization retarder and 0.2 % delayed catalyst, stirred under vacuum for 30 minutes, then added 37.3% inorganic filler, 5.6% molecular sieve dewatering agent, stirred under vacuum for 2 hours to obtain component A;

[0053] Component B is an isocyanate curing agent comprising liquefied diphenylmethane diisocyanate and polyphenyl polymethylene polyisocyanate;

[0054] Pack components A and B separately, and mix components A and B at a mass ratio of 5:1 to obtain a polyurethane structural adhesive with a long pot life and rapid strength increase.

Embodiment 2

[0056] In terms of mass percentage, add 20% castor oil polyol, 12% bisphenol A modified polyether triol, 10% environmentally friendly organic solvent, and 11.5% polyether hexaol to the reactor and heat to 100 ° C ~ 120 ° C , and stirred and dehydrated under vacuum for 1 to 2 hours, then cooled to 60 ° C, added to the planetary stirring mixer, and then added 1.0% viscosity-increasing additive, 0.4% viscosity reducing agent, 0.3% polymerization retarder and 0.2 % delayed catalyst, stirred under vacuum for 30 minutes, then added 37% inorganic filler, 7.6% molecular sieve dewatering agent, stirred under vacuum for 2 hours to obtain component A;

[0057] Component B is an isocyanate curing agent comprising liquefied diphenylmethane diisocyanate and polyphenyl polymethylene polyisocyanate;

[0058] Pack components A and B separately, and mix components A and B at a mass ratio of 5:1 to obtain a polyurethane structural adhesive with a long pot life and rapid strength increase.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com