Preparation method of lanthanum strontium manganese oxide film with negative poisson's ratio

A lanthanum strontium manganese oxide thin film, negative Poisson's ratio technology, applied in metal material coating process, vacuum evaporation coating, coating and other directions, to achieve the effect of low roughness, low cost and great application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) the used SrTiO 3 (001) The substrate is ultrasonically cleaned in acetone, absolute ethanol, and deionized water in sequence;

[0030] (2) La 0.7 Sr 0.3 MnO 3 The target material and the substrate in step (1) are put into the pulsed laser deposition equipment;

[0031] (3) Carry out vacuum operation on the pulse laser deposition equipment to reach a high vacuum state of 1×10 -4 Pa, after the vacuum degree is reached, the substrate is heated, and the heating temperature is 720°C;

[0032] (4) The pulsed laser deposition equipment in the high vacuum state obtained in step (3) is subjected to a flow oxygen circulation operation, and the oxygen pressure is 1×10 -2 Pa;

[0033] (5) Depositing the pulsed laser deposition equipment in step (4), the laser pulse width is 10ns, the laser energy is 180 mJ, and the laser frequency is 3Hz; the deposition time is 5min, and the thickness is 10nm. 0.7 Sr 0.3 MnO 3-δ film;

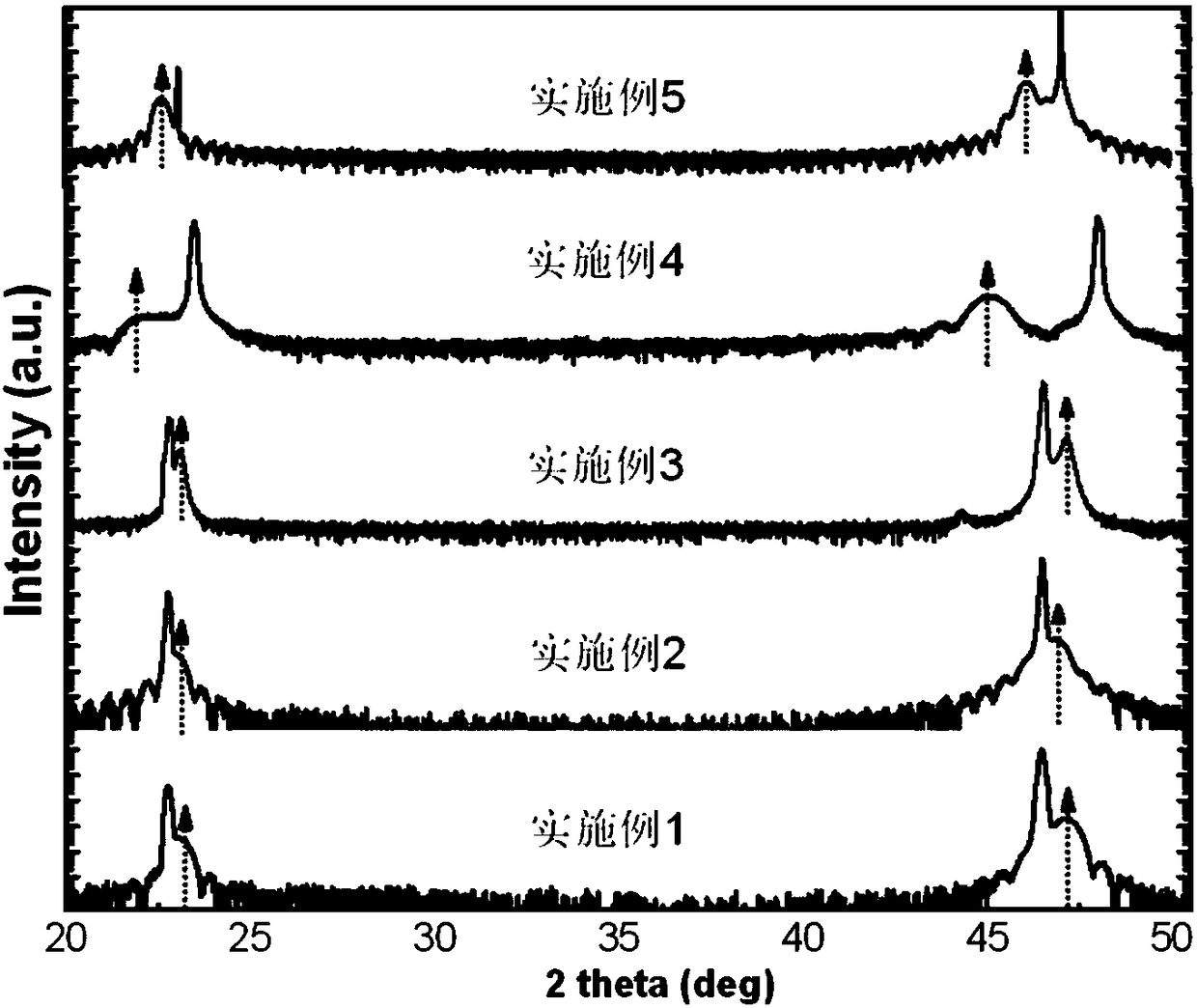

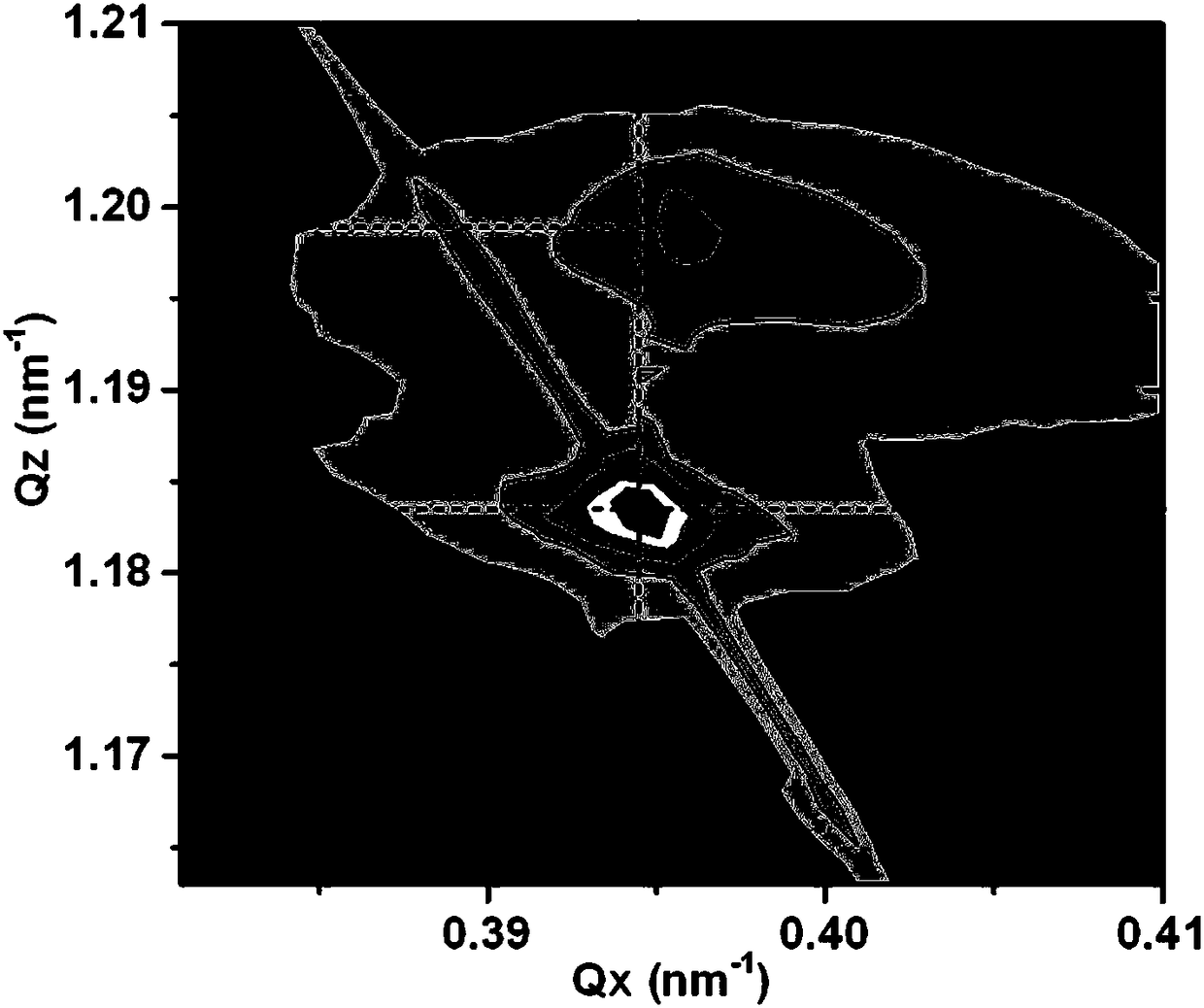

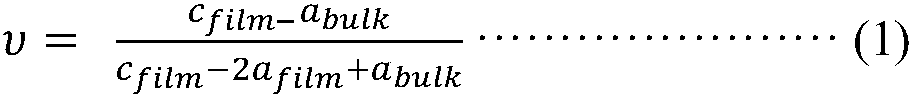

[0034] (6) Carry out XRD test to gained film, i...

Embodiment 2

[0040] The difference with embodiment 1 is:

[0041] (1) the used SrTiO 3 (001) The substrate is ultrasonically cleaned in acetone, absolute ethanol, and deionized water in sequence;

[0042] (2) La 0.7 Sr0.3 MnO 3 The target material and the substrate in step (1) are put into the pulsed laser deposition equipment;

[0043] (3) Carry out vacuum operation on the pulse laser deposition equipment to reach a high vacuum state of 1×10 -4 Pa, after the vacuum degree is reached, the substrate is heated, and the heating temperature is 730°C;

[0044] (4) The pulsed laser deposition equipment in the high vacuum state obtained in step (3) is subjected to a flow oxygen circulation operation, and the oxygen pressure is 1×10 -2 Pa;

[0045] (5) Depositing the pulsed laser deposition equipment in step (4), the laser pulse width is 10ns, the laser energy is 180 mJ, and the laser frequency is 3Hz; the deposition time is 15min, and the thickness is 68nm. 0.7 Sr 0.3 MnO 3-δ film;

[...

Embodiment 3

[0053] The difference with embodiment 1 is:

[0054] (1) the used SrTiO 3 (001) The substrate is ultrasonically cleaned in acetone, absolute ethanol, and deionized water in sequence;

[0055] (2) La 0.7 Sr 0.3 MnO 3 The target material and the substrate in step (1) are put into the pulsed laser deposition equipment;

[0056] (3) Carry out vacuum operation on the pulse laser deposition equipment to reach a high vacuum state of 1×10 -4 Pa, after the vacuum degree is reached, the substrate is heated, and the heating temperature is 730°C;

[0057] (4) The pulsed laser deposition equipment in the high vacuum state obtained in step (3) is subjected to a flow oxygen circulation operation, and the oxygen pressure is 1×10 -2 Pa;

[0058] (5) Depositing the pulsed laser deposition equipment in step (4), the laser pulse width is 10ns, the laser energy is 150mJ, and the laser frequency is 3Hz; the deposition time is 25min, and the thickness is 78nm. 0.7 Sr 0.3 MnO 3-δ film;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com