Method for simulating TBPB half-cage type hydrate membrane separation mixed gas

A mixed gas and hydrate technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of insufficient kinetics, affecting the industrialization process of hydrate separation technology application, and low gas storage capacity, so as to save experiments Cost, poor separation effect, simple separation and purification method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

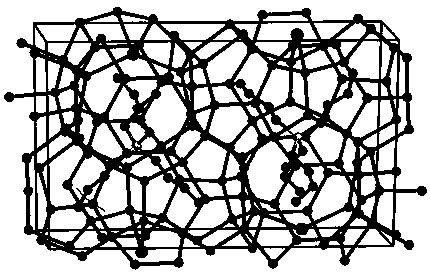

[0042] (1) Use Materials Studio software to establish the unit cell of TBPB hemiclathrate hydrate, such as figure 1 shown; and build CO 2 and H 2 Molecular model of the obtained TBPB hemiclathrate hydrate structure and CO 2 and H 2 The coordinate information of the molecule is converted into the input coordinate file required by the molecular simulation software.

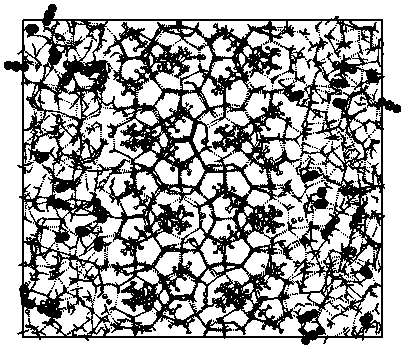

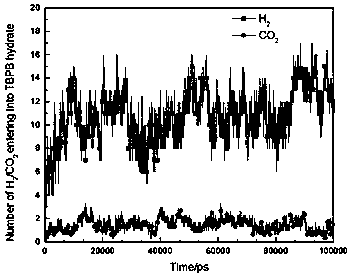

[0043] (2) Using GROMACS software, bring in the coordinate file obtained in step (1), and expand the unit cell of TBPB hemiclathrate hydrate by 2×2×2, and the size is 4.2130×2.5314×2.3984nm. And expand the number of gas molecules in proportion to construct 50% CO 2 and 50%H 2 The mixed gas model is filled with water molecules, and the TBPB semi-cage hydrate structure and the mixed gas model are superimposed in the order of gas-liquid-hydrate-gas-liquid. The superimposed initial structure model is composed of liquid-solid two-phase, and the size is 4.2130×2.5314×4.7968nm, so as to obtain the initial configurati...

Embodiment 2

[0055] (1) Use the Materials Studio software to establish the unit cell of TBPB hemiclathrate hydrate, and establish the CO 2 and N 2 Molecular model, the obtained TBPB hemiclathrate hydrate structure and CO 2 and N 2 The coordinate information of the molecule is converted into the input coordinate file required by the molecular simulation software.

[0056] (2) Using GROMACS software, bring in the coordinate file obtained in step (1), and expand the unit cell of TBPB hemiclathrate hydrate by 2×2×2, and the size is 4.2130×2.5314×2.3984nm. And expand the number of gas molecules in proportion to construct 50% CO 2 and 50%N 2 The mixed gas model is filled with water molecules, and the TBPB semi-cage hydrate structure and the mixed gas model are superimposed in the order of gas-liquid-hydrate-gas-liquid. The superimposed initial structure model is composed of liquid-solid two-phase, and the size is 4.213×2.5314×4.7968nm, thus obtaining the initial configuration information of...

Embodiment 3

[0068] (1) Use Materials Studio software to establish the unit cell of TBPB hemiclathrate hydrate, and establish CH 4 and C 2 h 6 Molecular model, the obtained TBPB hemiclathrate hydrate structure and CH 4 and C 2 h 6 The coordinate information of the molecule is converted into the input coordinate file required by the molecular simulation software.

[0069] (2) Using GROMACS software, bring in the coordinate file obtained in step (1), and expand the unit cell of TBPB hemiclathrate hydrate by 2×2×2, and the size is 4.2130×2.5314×2.3984nm. And expand the number of gas molecules in proportion to construct 50% CH 4 and 50%C 2 h 6 The mixed gas model is filled with water molecules, and the TBPB semi-cage hydrate structure and the mixed gas model are superimposed in the order of gas-liquid-hydrate-gas-liquid. The superimposed initial structure model is composed of liquid-solid two-phase, and the size is 4.213×2.5314×4.7968nm, thus obtaining the initial configuration informa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com