Plastic metal-ceramic laminated coating die-casting mould and preparation method thereof

A technology for cermets and die-casting molds, which is applied in the coating process of metal materials, coatings, and plating of superimposed layers. It can solve problems such as unsatisfactory corrosion resistance, mold fatigue cracks, and unsatisfactory deformation resistance. The effect of improved mold life, improved service life, and excellent deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

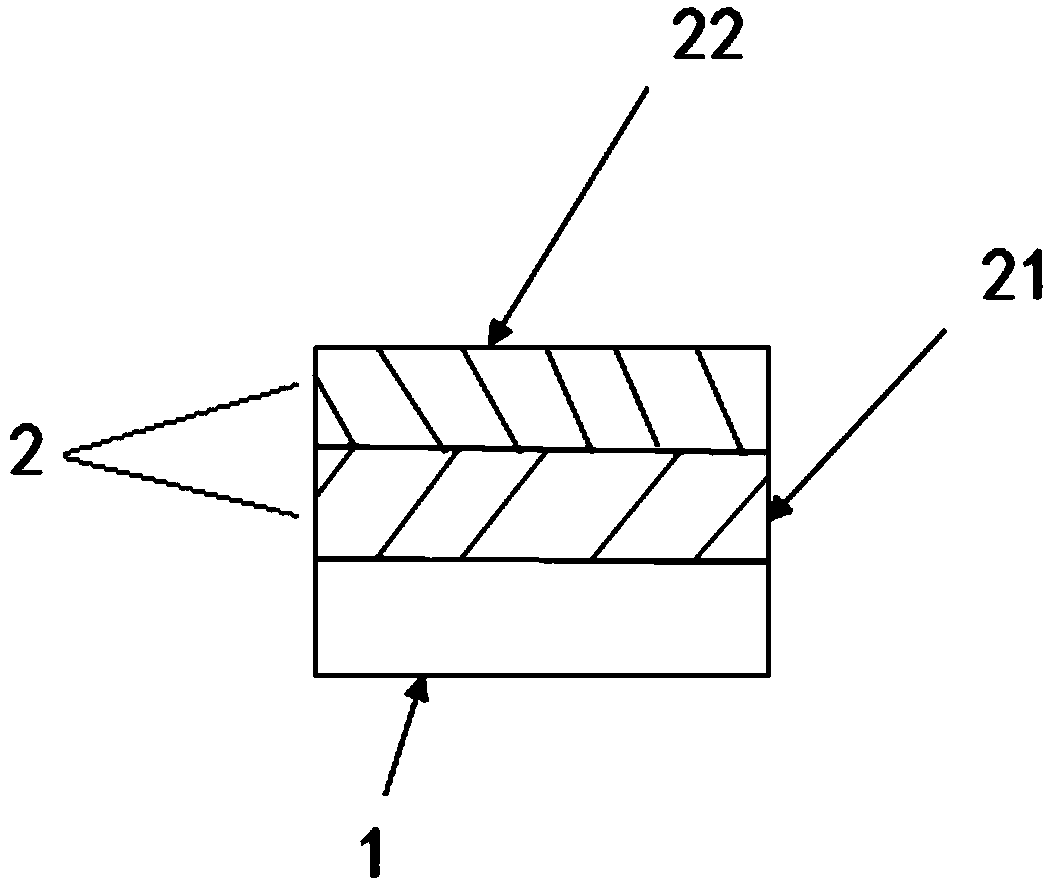

[0028] see figure 1 , a plastic metal-ceramic laminated coating die-casting mold, which is composed of a mold base 1 and a surface adhesion layer 2; the surface adhesion layer 2 is composed of a high-plasticity metal layer 21 and a heat-resistant ceramic layer 22; wherein, the high-plasticity metal layer The thickness of 21 is set to satisfy that the mold base does not undergo accumulative plastic deformation during its heating and cooling process, and the thickness is 50um; the material selection of the heat-resistant ceramic layer 22 ensures that it will not crack under force during its heating and cooling process, and its thickness is 10um .

[0029] The highly plastic metal layer 21 is a coating mainly composed of tantalum simple substance. The metallurgical bond between the high-plasticity metal layer 21 and the surface of the mold base 1 is formed, and the yield strength of the high-plasticity metal layer 21 is greater than the yield strength at which accumulative plast...

Embodiment 2

[0038] A plastic metal-ceramic laminated coating die-casting mold, including a mold base 1 and a surface attachment layer 2, the surface attachment 2 is composed of a high-plasticity metal layer 21 and a heat-resistant ceramic layer 22; wherein, the thickness of the high-plasticity metal layer 21 The thickness is 80um if the mold base does not undergo accumulative plastic deformation during the heating and cooling process; the material of the heat-resistant ceramic layer 22 is selected to ensure that it will not crack under force during the heating and cooling process, and the thickness is 15um.

[0039] The high-plasticity metal layer 21 is a coating mainly composed of tantalum simple substance. The metallurgical bond between the high-plasticity metal layer 21 and the surface of the mold base 1 is formed, and the yield strength of the high-plasticity metal layer 21 is greater than the yield strength at which accumulative plastic deformation just occurs. The heat-resistant cer...

Embodiment 3

[0048] A plastic metal-ceramic laminated coating die-casting mold, comprising a mold base 1 and a surface adhesion layer 2; the surface adhesion layer 2 is composed of a high-plasticity metal layer 21 and a heat-resistant ceramic layer 22; wherein, the high-plasticity metal layer 21 The thickness is set to ensure that the mold base does not undergo accumulative plastic deformation during the heating and cooling process, and the thickness is 50um; the material of the heat-resistant ceramic layer 22 is selected to ensure that it will not crack under force during the heating and cooling process, and the thickness is 10um.

[0049] The highly plastic metal layer 21 is a coating mainly composed of tantalum and nickel, 40% of which is nickel, and the balance is tantalum. The metallurgical bond between the high-plasticity metal layer 21 and the surface of the mold base 1 is formed, and the yield strength of the high-plasticity metal layer 21 is greater than the yield strength at which...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com