Anti-aging table-board

An anti-aging and table board technology, applied in the field of table boards, can solve the problems of poor aging resistance of high-density polyethylene, low resistance to environmental stress cracking, short service life of table boards, etc., and achieves improved aging resistance and excellent emulsification. and dispersion, the effect of improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

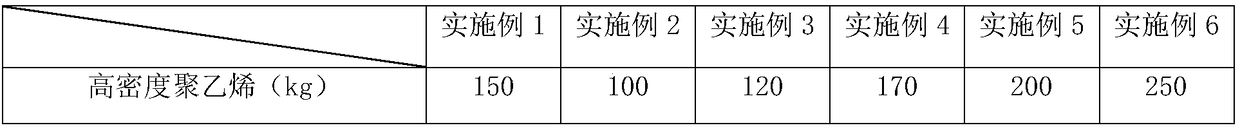

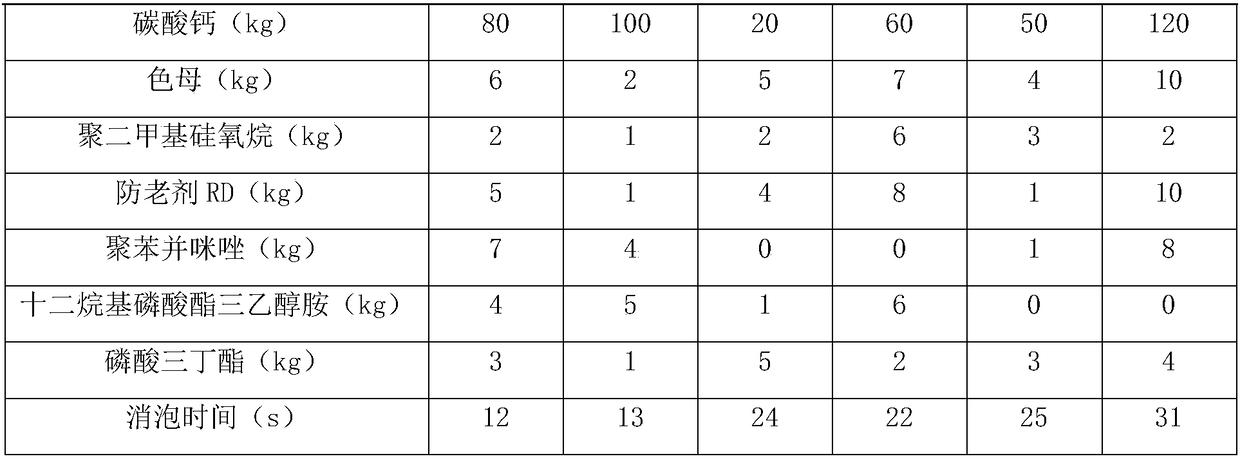

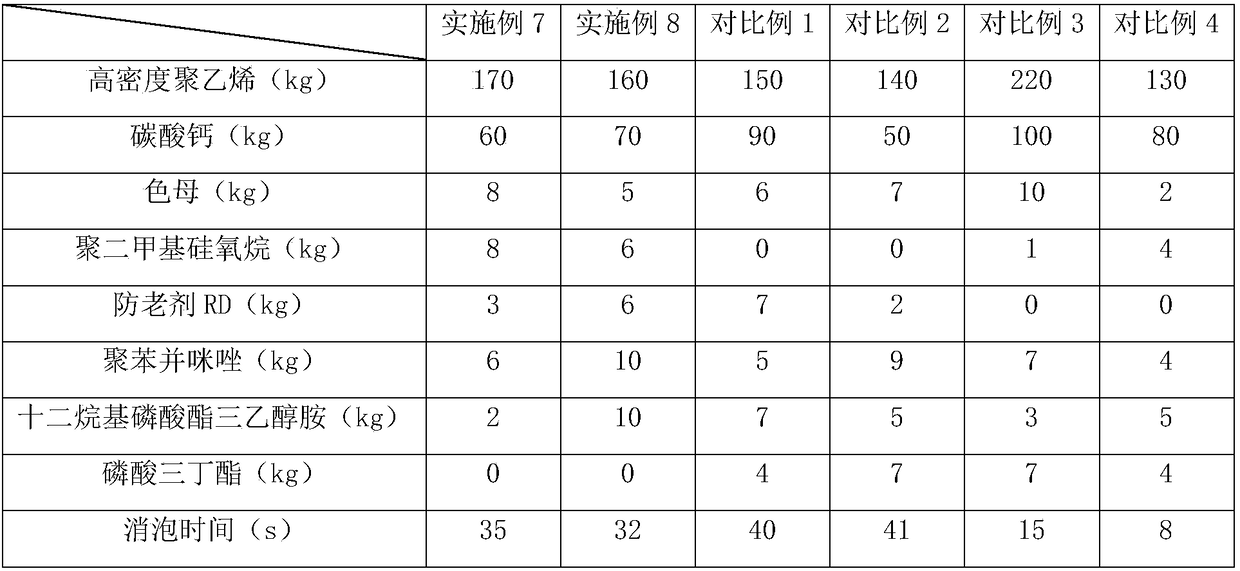

Embodiment 1

[0030] Example 1: An anti-aging table top, the components and parts by weight in the raw materials are shown in Table 1. The preparation method of anti-aging table board comprises the following steps,

[0031] Step 1, heat and melt high-density polyethylene, put in calcium carbonate, color masterbatch, polydimethylsiloxane, anti-aging agent RD, polybenzimidazole, dodecyl phosphate triethanolamine and tributyl phosphate, fully Stir to obtain the embryo body,

[0032] Step 2, sending the embryo body into the mold for pre-blowing and stretching, and then performing high-pressure blow molding,

[0033] Step 3, exhaust and obtain the finished product.

Embodiment 2

[0034] Example 2, an anti-aging table top, differs from Example 1 in that the components and parts by weight in the raw materials are shown in Table 1.

Embodiment 3

[0035] Embodiment 3: An anti-aging table top, the components and parts by weight in the raw materials are shown in Table 1. The preparation method of anti-aging table board comprises the following steps,

[0036] Step 1: Heat and melt high-density polyethylene, add calcium carbonate, color masterbatch, polydimethylsiloxane, anti-aging agent RD, dodecyl phosphate triethanolamine and tributyl phosphate, and stir fully to obtain an embryo body ,

[0037] Step 2, sending the embryo body into the mold for pre-blowing and stretching, and then performing high-pressure blow molding,

[0038] Step 3, exhaust and obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com