Spraying-free toughened nylon 6 material and preparation method thereof

A spray-free, nylon technology, applied in the field of polymer material modification, can solve the problems of prolonging the production cycle, surrounding environmental pollution, waste of resources, etc., and achieve the effects of promoting uniform dispersion, improving compatibility, and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

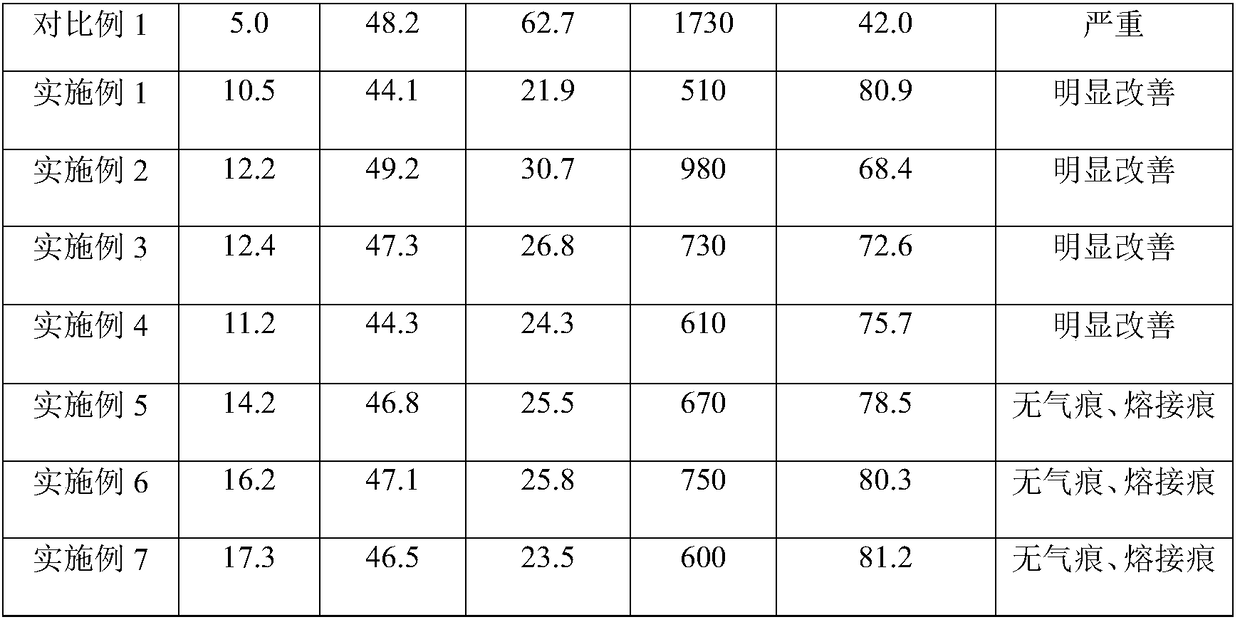

Embodiment 1

[0041] A spray-free toughened nylon 6 material, in terms of mass percentage, its raw material is composed of the following components: 59.4% nylon 6 resin, 15% toughening agent, 12% plasticizer, 6% maleic anhydride grafted polypropylene, 0.6% oxidized polyethylene wax, 0.5% flow modifier, 0.5% antioxidant, 1.0% lubricant, 5% metal masterbatch; the nylon 6 is medium viscosity nylon 6; the toughening agent is horse Maleic anhydride grafted POE, the grafting rate is 0.8%; the plasticizer is caprolactam; the maleic anhydride grafted polypropylene, the grafting rate is 0.8%; the flow modifier is trimellitic anhydride ; The antioxidant is a mixture of antioxidant 1098 and antioxidant 168, the mass ratio of the two is 1:1; the lubricant is OP wax; the active ingredient of the metal masterbatch is aluminum pink.

[0042] The dried nylon 6, toughener, plasticizer, maleic anhydride grafted polypropylene, dispersant, flow modifier, antioxidant, lubricant and metal masterbatch according ...

Embodiment 2

[0044]A spray-free toughened nylon 6 material, in terms of mass percentage, its raw material is composed of the following components: 76.9% nylon 6 resin, 10% toughening agent, 7% plasticizer, 3% maleic anhydride grafted polypropylene, 0.2% dispersant, 0.2% flow modifier, 0.2% antioxidant, 0.5% lubricant, 2% metal masterbatch; the nylon 6 is medium viscosity nylon 6; the toughening agent is maleic anhydride Grafted POE, its graft rate is 0.8%; Described plasticizer is caprolactam; Described maleic anhydride grafted polypropylene, graft rate is 0.8%; Described flow modifier is trimellitic anhydride; The antioxidant is a mixture of antioxidant 1098 and antioxidant 168, the mass ratio of the two is 1:1; the lubricant is OP wax; the active ingredient of the metal masterbatch is silver powder.

[0045] The dried nylon 6, toughening agent, plasticizer, maleic anhydride grafted polypropylene, oxidized polyethylene wax, flow modifier, antioxidant, lubricant and metal masterbatch in th...

Embodiment 3

[0047] A spray-free toughened nylon 6 material, in terms of mass percentage, its raw material consists of the following components: 71.2% nylon 6 resin, 12% toughening agent, 8% plasticizer, 4% maleic anhydride grafted polypropylene, 0.5% oxidized polyethylene wax, 0.3% flow modifier, 0.2% antioxidant, 0.8% lubricant, 3% metal masterbatch; the nylon 6 is medium viscosity nylon 6; the toughening agent is horse Maleic anhydride grafted POE, the grafting rate is 0.8%; the plasticizer is caprolactam; the maleic anhydride grafted polypropylene, the grafting rate is 0.8%; the flow modifier is trimellitic anhydride The antioxidant is a mixture of antioxidant 1098 and antioxidant 168, the mass ratio of the two is 1:1; the lubricant is OP wax; the active ingredient of the metal masterbatch is zinc pink.

[0048] The dried nylon 6, toughening agent, plasticizer, maleic anhydride grafted polypropylene, oxidized polyethylene wax, flow modifier, antioxidant, lubricant and metal masterbatc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com