A kind of rc-igbt device and preparation method thereof

A device and semiconductor technology, applied in the field of reverse conduction insulated gate bipolar transistor devices and their preparation, can solve the problems of poor reverse recovery ability of diodes, uneven current distribution in drift region, uneven heat distribution, etc., and achieve improved Latch-up resistance, optimization of forward conduction characteristics, effects of avoiding latch-up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

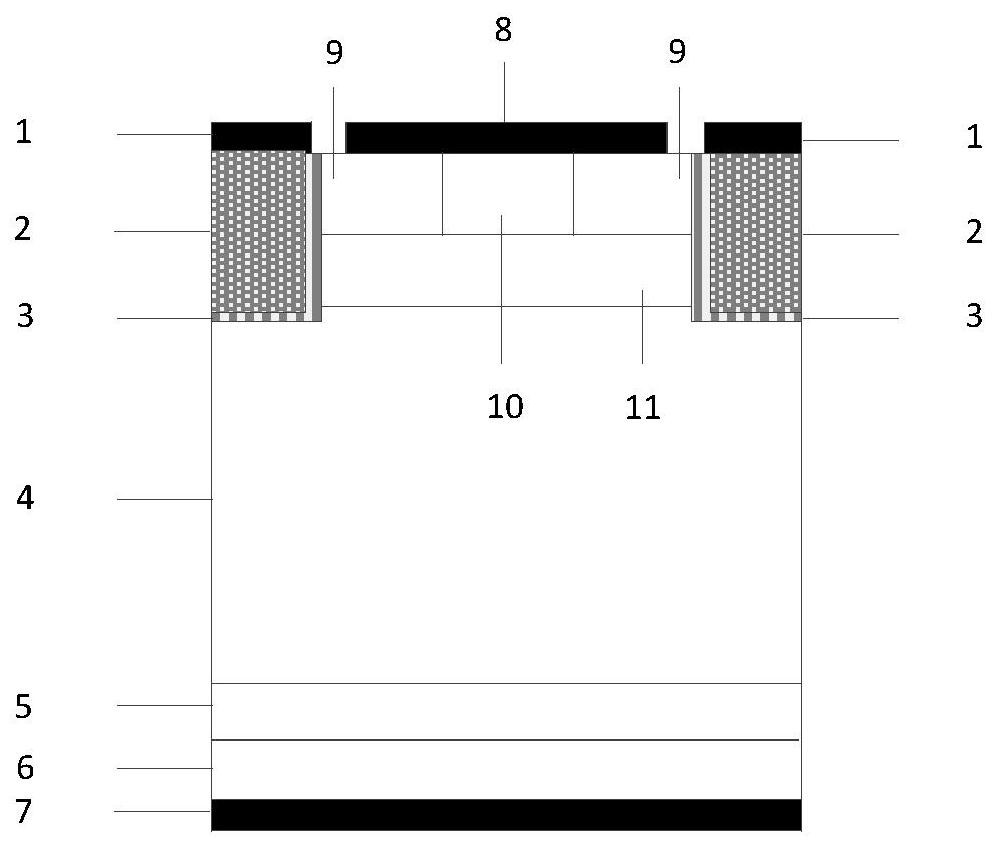

[0057] An RC-IGBT device whose cell structure is as follows Figure 4As shown, it includes: an N-type silicon drift region 4, an emitter structure and a gate structure located on the upper layer of the N-type silicon drift region 4, and a collector structure located on the lower layer of the N-type silicon drift region 4; the emitter structure includes a metal emitter Pole 8, N+ silicon emitter region 9, P+ silicon contact region 10 and P-type silicon base region 11, the P-type silicon base region 11 is located at the top of the N-type silicon drift region 4, and the N+ silicon emitter region 9 is located at the top of the P-type silicon On both sides of the top of the base region 11, the P+ silicon contact region 10 is located between and connected to the N+ silicon emitter region 9, and the metal emitter 8 is located on the upper surface of the N+ silicon emitter region 9 and the P+ silicon contact region 10; The gate structure includes a metal gate electrode 1, polysilicon ...

Embodiment 2

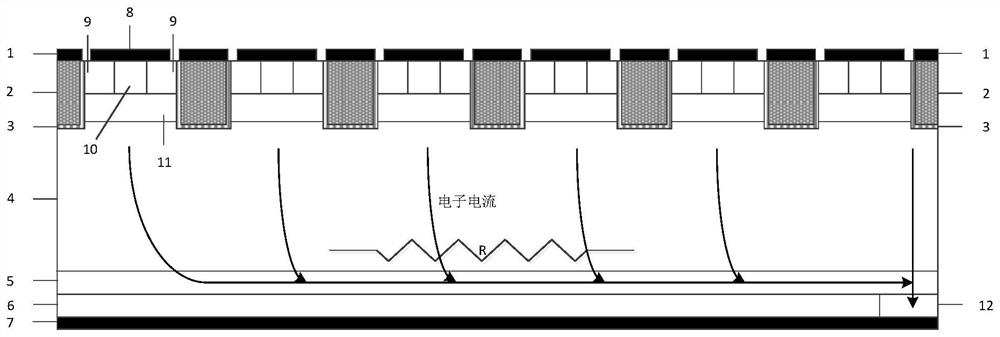

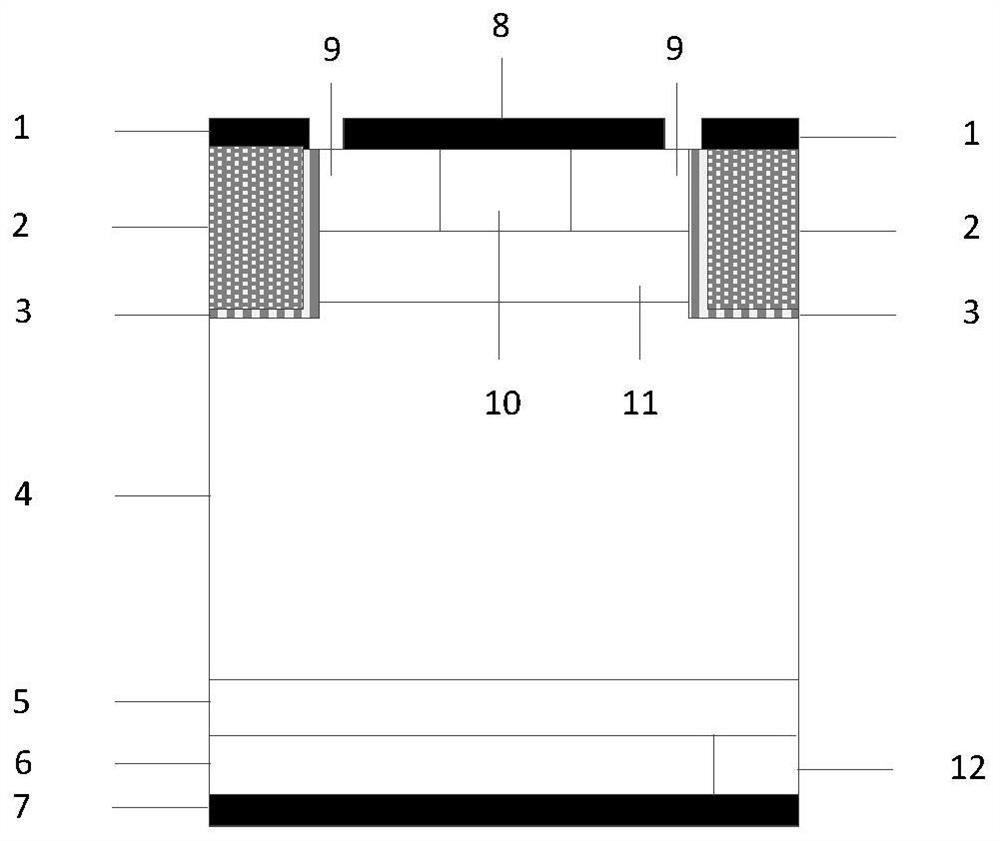

[0061] Compared with Embodiment 1, this embodiment differs in that: the number of P-type silicon carbide collector short-circuit regions 6 and N-type silicon carbide collector short-circuit regions 13 is different; in this embodiment, the N-type silicon carbide collector short-circuit regions 13 and The number of P-type silicon collector regions 6 is not less than two, and a plurality of N-type silicon carbide collector short-circuit regions 13 and a plurality of P-type silicon collector regions 6 are arranged at intervals, such as Figure 5 shown.

[0062] Compared with Example 1, due to the position away from the collector short-circuit area, the current needs to pass through a lateral resistance to reach the collector short-circuit area, and because the Si / SiC heterojunction is evenly distributed at the metal collector 7 and the interval is small, reducing The resistance value of the lateral resistance formed by the RC-IGBT above the P-type silicon collector region 6 is red...

Embodiment 3

[0064] The difference between this embodiment and Embodiment 1 is that: the N-type silicon carbide collector short-circuit region 13 is formed by gradient doping; in this embodiment, the gradient doping specifically refers to the N-type silicon carbide collector short-circuit region 13 The doping concentration gradually decreases from top to bottom (that is, the doping concentration is from the junction of the N-type silicon field resistance layer 5 and the N-type silicon carbide collector short-circuit region 13 to the N-type silicon carbide collector short-circuit region 13 and the metal collector short-circuit region. The direction of the interface of the electrode 7 gradually decreases).

[0065] Such as Figure 7 Shown is the energy band diagram of the n-Si / N-SiC heterojunction formed by the gradually doped N-type silicon carbide collector short-circuit region 13 and the N-type silicon field stop layer 5 . Compared with Embodiment 1, the additional electron barrier provi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com