A short-circuited anode soi LIGBT with an anode pinch-off slot

A technology of anode clamp and anode tank, which is applied in the direction of circuits, semiconductor devices, electrical components, etc., can solve the problems that affect the uniformity of device current distribution, large conduction voltage drop, and low anode hole injection efficiency, so as to eliminate voltage foldback Phenomenon, fast turn-off speed, effect of low conduction voltage drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

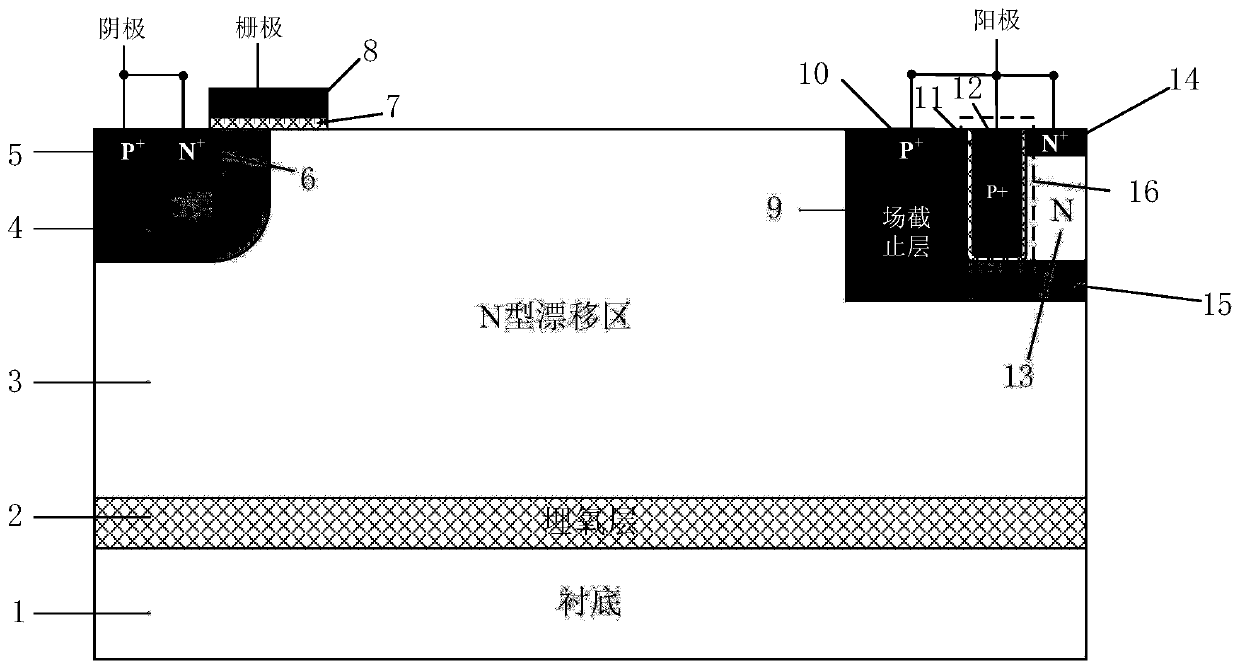

[0016] like figure 1 As shown, the structure of this example includes a P substrate 1, a buried oxide layer 2, and a top semiconductor layer stacked sequentially from bottom to top; the top semiconductor layer has an N-type drift region 3, and the device is along the In the lateral direction from one side to the other there are cathode structures, gate structures and anode structures in sequence.

[0017] The cathode structure includes a P well region 4, a P+ body contact region 5 located on the upper surface of the P well region 4 away from the anode structure, and an N+ cathode region 6 in contact with the P+ body contact region 5, and the P+ body contact region 5 and the N+ cathode region 6 have a common terminal as the cathode. There is a distance between the edges of the P+ body contact region 5 and the N+ cathode region 6 and the edge of the P well region 4 .

[0018] The gate structure is composed of an insulating medium 7 and a conductive material 8 on it, and the le...

Embodiment 2

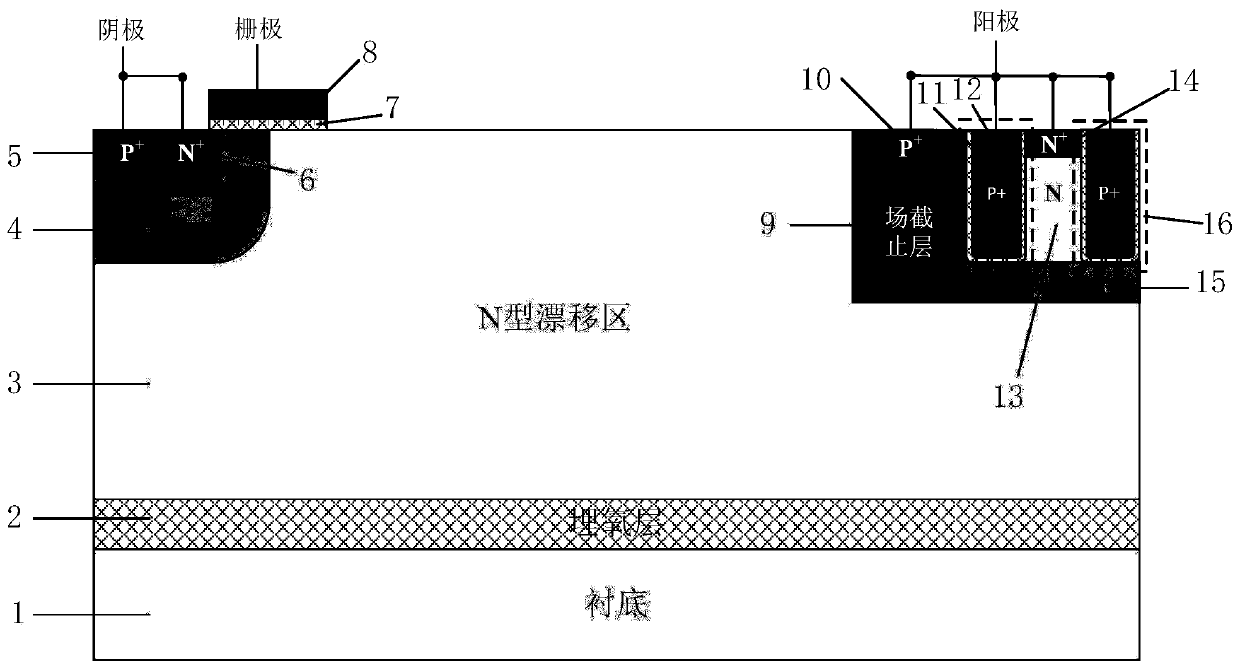

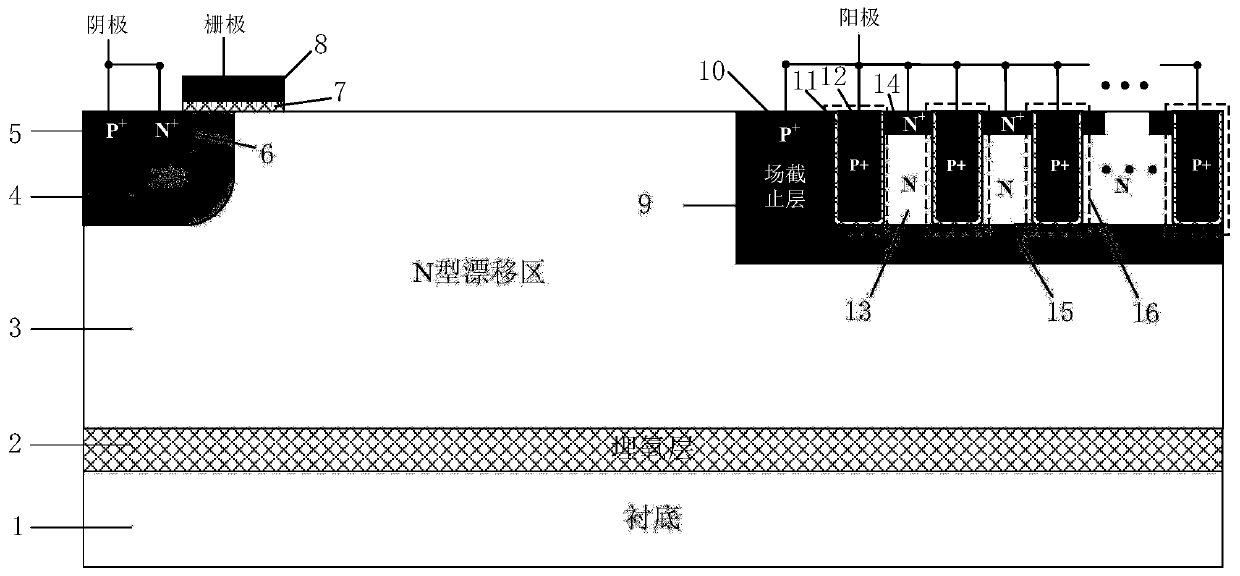

[0023] like figure 2 and 3 As shown, the difference between this example and Embodiment 1 is that there are two or more anode groove grid structures 16; the position of an anode groove 16 near the cathode side is as described in claim 1, and the rest of the anode groove 16 On the side away from the cathode structure, there are N-type doped regions 13 and N+anode regions 14 above the N-type doped regions 13 on both sides. Compared with Example 1, the design in this example uses two or more anode tanks, which enhances the depletion effect of P-type impurities in the anode tank on the low-concentration N-type doped region, and at the same time, increases the accumulation of more This not only enhances conductance modulation, further reduces the on-voltage drop, but also accelerates the extraction of electrons stored in the drift region, reducing turn-off time and turn-off loss.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com