Preparation method of phosphorus building gypsum base light self-leveling mortar

A technology of self-leveling mortar and phosphorous building gypsum is applied in the field of comprehensive utilization of waste resources and building materials, which can solve the problems of inability to comprehensively cost competition, lack of market competitiveness, large amount of materials, etc. The product performance is satisfied, the quality performance is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Phosphogypsum-based self-leveling mortar, its components and mass fraction ratio are: phosphogypsum 75%, dry sand 1%, light aggregate 10%, cement 5%, active activator 5%; water repellent: 1% ; High-performance plasticizer 0.5%, anti-sedimentation aid 0.1%, flocculation aid 0.1%; gypsum retarder 0.2%, high molecular polymer 2%; high-performance defoamer: 0.1%.

[0029] Preparation method: take each component according to the stated ratio, and stir evenly to obtain the product—phosphogypsum-based self-leveling mortar.

Embodiment 2

[0031] Phosphogypsum-based self-leveling mortar, its components and mass fraction ratio are: phosphogypsum 80%, dry sand 4%, light aggregate 8%, active activator 5%; water repellent: 1%; high-performance plastic Chemical agent 0.5%, anti-sedimentation additive 0.1%, flocculation additive 0.1%; gypsum retarder 0.2%, polymer 1%; high-performance defoamer: 0.1%.

[0032] Preparation method: take each component according to the stated ratio, and stir evenly to obtain the product—phosphogypsum-based self-leveling mortar.

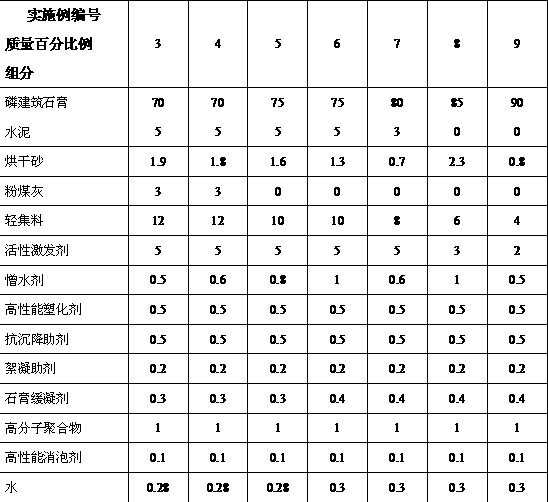

Embodiment 3—9

[0034] Phosphogypsum-based self-leveling mortar, its composition and percentage examples are shown in the table below:

[0035]

[0036] The preparation method of embodiment 3-9 is with embodiment 1 or 2, omission.

[0037] In the above examples: phosphorus building gypsum 70%~90%, dry sand 0%~20%, cement 0%~20%, fly ash 0%~5%, light aggregate: 5~20%, active excitation Hydrophobic agent: 0%~3%; high performance plasticizer 0.1%~1%, anti-sedimentation additive 0%~0.2%, flocculation additive 0%~0.2%; gypsum retarder Agent 0.01%~0.4%, polymer 0%~3%; high-performance defoamer: 0.05%~0.3%.

[0038] In the content of the present invention: the phosphorus building gypsum is prepared by calcining the industrial waste slag discharged in the process of producing phosphate fertilizer β -Type hemihydrate gypsum, its flexural strength ≥ 2.0MPa, compressive strength ≥ 3.0MPa, initial setting time ≥ 3min, phosphorus building gypsum can be replaced by desulfurized building gypsum, natura...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Initial setting time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com