Method for continuously recovering PGMEA (propylene glycol methyl ether acetate) from PGMEA/aqueous solution by utilizing azeotropic distillation

A technology of azeotropic distillation and azeotropic distillation column, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as inability to separate and purify, low azeotrope, etc., to reduce production costs, Reduced pressure, the effect of reducing the content of organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

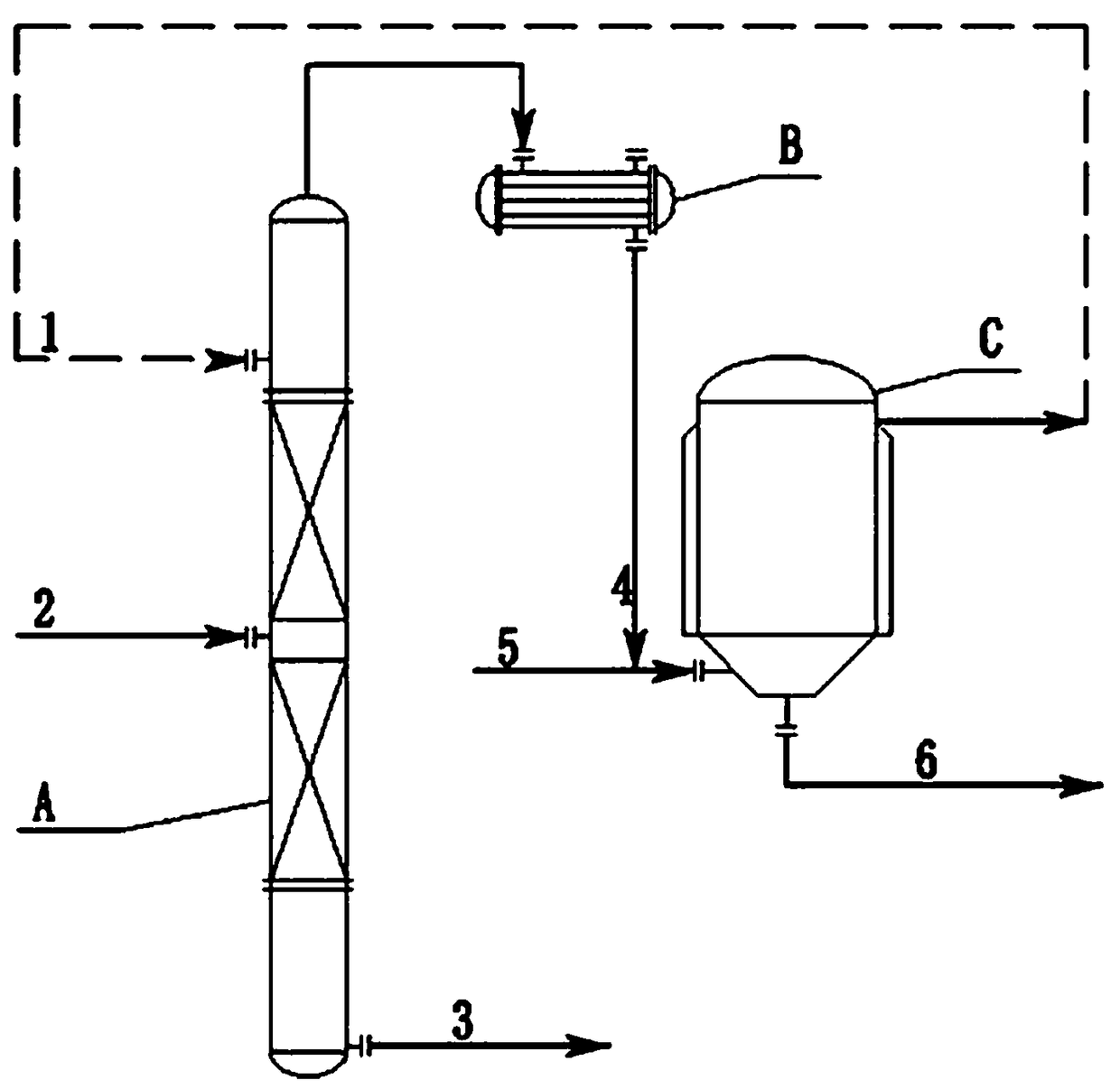

[0022] Such as figure 1 Shown, the massfraction of PGMEA in the PGMEA / water solution 2 to be treated is 1%, and feed flow rate is 300kg / h, and the circulating flow rate of entrainer cyclohexane 1 is 891kg / h, and now entrainer consumption is 3 times the quality of water. The above-mentioned materials are continuously fed into the azeotropic rectification tower A containing 20 theoretical plates, the PGMEA / water solution to be treated is continuously fed from the 10th theoretical plate of the azeotropic rectification tower, and the entrainer cyclohexane is fed from the top of the tower Continuous feeding, the material is heated and vaporized in the bottom of the azeotropic distillation column, and then enters the gas phase condenser B at the top of the azeotropic distillation column, the gas phase is condensed into liquid in the condenser, and the gas phase condensate at the top of the azeotropic distillation column 4 and fresh entrainer 5 enter the phase separation tank C, and...

Embodiment 2

[0025] The difference between the present embodiment and embodiment one is: the massfraction of PGMEA in the PGMEA / water solution is 50%, the feed flow rate is 100kg / h, and the circulation flow rate of entrainer hexanaphthene is 250kg / h. When the amount of entrainer is 5 times of water quality. The above-mentioned materials are continuously fed to an azeotropic rectification tower containing 15 theoretical plates, the PGMEA / water solution to be treated is continuously fed from the 10th theoretical plate of the azeotropic rectification tower, and the entrainer cyclohexane is continuously fed from the top of the tower. Feed, the material is heated and vaporized in the bottom of the azeotropic distillation column and enters the condenser upwards, the gas phase is condensed into a liquid in the condenser, the condensate and fresh entrainer enter the phase separation tank, water and cyclohexane in the condensate The mass fractions were 16.7%, 83.3%, respectively. The flow rate of ...

Embodiment 3

[0028] The difference between this embodiment and embodiment two is: the mass fraction of PGMEA in the PGMEA / water solution is 99%, the feed flow rate is 500kg / h, and the recirculation flow rate of entrainer hexanaphthene is 35kg / h, this When the amount of entrainer is 7 times of water quality. The above-mentioned materials are continuously fed to an azeotropic rectification tower containing 30 theoretical plates, the PGMEA / water solution to be treated is continuously fed from the 16th theoretical plate of the azeotropic rectification tower, and the entrainer cyclohexane is continuously fed from the top of the tower. Feed, the material is heated and vaporized in the bottom of the azeotropic distillation column and enters the condenser upwards, the gas phase is condensed into a liquid in the condenser, the condensate and fresh entrainer enter the phase separation tank, water and cyclohexane in the condensate The mass fractions were 12.5%, 87.5%, respectively. The flow rate of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com