Toughening material for ultra-low temperature resistant injection molding grade nylon and preparation method thereof

An ultra-low temperature, injection molding technology, applied in the field of polymer materials, can solve the problems of nylon cable ties easy stress cracking, poor product dimensional stability, nylon pipes easy to crack, etc., to achieve good low temperature resistance, low density filling, high filling sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

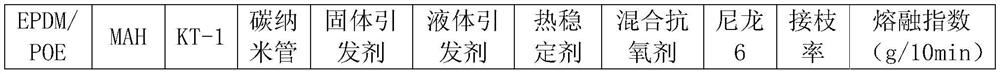

[0024] The effect of the amount of solid initiator on the toughening agent was studied.

[0025]First, under the condition of 170°C, blend 75 parts of EPDM rubber and 25 parts of ethylene octene copolymer for 5 minutes, add 7 parts of dibenzoyl peroxide, and the reaction time is 7 minutes to obtain EPDM / POE thermoplastic elastic Body; 100 parts of polypropylene, 0.7 parts of maleic anhydride, 0.1 parts of DCP, 0.3 parts of zinc stearate, 0.2 parts of 1010, placed in a high-speed mixer and mixed evenly, the mixing time was set to 5min, and extruded by twin-screw Preparation of KT-1. Extrusion temperature setting: Zone 1 170°C, Zone 2 175°C, Zone 3 180°C, Zone 4 185°C, Zone 5 190°C, Zone 6 190°C, Zone 7 185°C, Zone 8 180°C, Zone 9 175°C , head 190°C; the residence time in each zone is 7 seconds; the rotation speed of the main engine is: 500r / min; KT-1 is prepared; then, take 85 parts of EPDM / POE thermoplastic elastomer, 1.5 parts of maleic anhydride, 2.5 parts of KT- 1. 3 part...

Embodiment 2

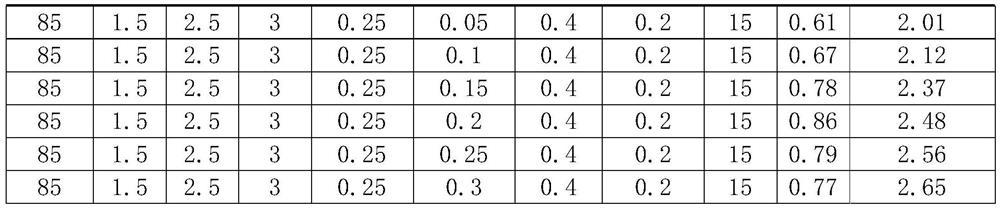

[0031] Study on the Effect of Liquid Initiator Amount on Toughener .

[0032] First, under the condition of 170°C, blend 75 parts of EPDM rubber and 25 parts of ethylene octene copolymer for 5 minutes, add 7 parts of dibenzoyl peroxide, and the reaction time is 7 minutes to obtain EPDM / POE thermoplastic elastic Body; 100 parts of polypropylene, 0.9 part of maleic anhydride, 0.3DCP, 0.5 part of zinc stearate, 0.3 part of 1010 were placed in a high-speed mixer and mixed evenly, the mixing time was set at 5min, and KT was prepared by twin-screw extrusion -1. Extrusion temperature setting: Zone 1 170°C, Zone 2 175°C, Zone 3 180°C, Zone 4 185°C, Zone 5 190°C, Zone 6 190°C, Zone 7 185°C, Zone 8 180°C, Zone 9 175°C , head 190°C; the residence time in each zone is 7 seconds; the rotation speed of the main engine is: 500r / min; KT-1 is prepared. Then, take 85 parts of EPDM / POE thermoplastic elastomers, 1.5 parts of maleic anhydride, 2.5 parts of KT-1, 3 parts of carbon nanotubes, 0.2...

experiment example 3

[0038] Study on the effect of the amount of maleic anhydride on the toughening agent .

[0039] First, under the condition of 170°C, blend 75 parts of EPDM rubber and 25 parts of ethylene octene copolymer for 5 minutes, add 7 parts of dibenzoyl peroxide, and the reaction time is 7 minutes to obtain EPDM / POE thermoplastic elastic Body; 100 parts of polypropylene, 0.8 parts of maleic anhydride, 0.25 parts of DCP, 0.35 parts of zinc stearate, and 0.2 parts of 1010 were placed in a high-speed mixer and mixed uniformly. The mixing time was set at 5 minutes, and prepared by twin-screw extrusion KT-1. Extrusion temperature setting: Zone 1 170°C, Zone 2 175°C, Zone 3 180°C, Zone 4 185°C, Zone 5 190°C, Zone 6 190°C, Zone 7 185°C, Zone 8 180°C, Zone 9 175°C , head 190°C; the residence time in each zone is 7 seconds; the rotation speed of the main engine is: 500r / min; KT-1 is prepared. Then, take 85 parts of EPDM / POE thermoplastic elastomer, 2.5 parts of KT-1, 3 parts of carbon nanot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com