Foamed plastics for automobile interior and preparation method thereof

A foam plastic and automotive interior technology, applied in the field of plastics, can solve the problems of poor sound absorption effect and mechanical properties of polyurethane foam materials, and achieve good sound absorption effect, good compression strength and impact strength, and a wide range of raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

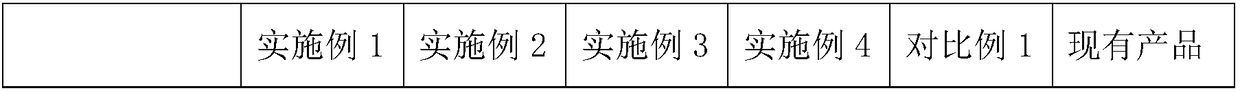

Examples

Embodiment 1

[0019] A kind of foamed plastics for automotive interior, comprising the following raw materials in parts by weight: 90 parts of melamine resin, 8 parts of polyvinyl acetal, 16 parts of starch, 14 parts of cellulose, 6 parts of surfactant, 6 parts of foaming agent, 2 parts of crosslinking agent, 13 parts of curing agent, 7 parts of methacrylic acid, 10 parts of methyl benzoate, 13 parts of acrylonitrile and 5 parts of citrus. Starch includes a mixture of pea starch, corn starch, potato starch, and sorghum starch, and cellulose includes a crushed mixture of chaff, bran, and peanut bran.

[0020] The preparation method of the foamed plastics for the automotive interior, the specific steps are as follows:

[0021] Step 1, mixing melamine resin and polyvinyl acetal and performing condensation reaction under catalyst conditions to obtain a condensation product;

[0022] Step 2, clean the citrus and freeze-dry it, then crush it to 70 mesh, add water to the citrus powder and ultraso...

Embodiment 2

[0027] A kind of foamed plastics for automotive interior, comprising the following raw materials in parts by weight: 100 parts of melamine resin, 12 parts of polyvinyl acetal, 19 parts of starch, 16 parts of cellulose, 8 parts of surfactant, 7.5 parts of foaming agent, 2.6 parts of crosslinking agent, 14 parts of curing agent, 9 parts of methacrylic acid, 14 parts of methyl benzoate, 15 parts of acrylonitrile and 6 parts of citrus. The particle size of cellulose is 120um.

[0028] The preparation method of the foamed plastics for the automotive interior, the specific steps are as follows:

[0029] Step 1, mixing melamine resin and polyvinyl acetal and performing condensation reaction under catalyst conditions to obtain a condensation product;

[0030] Step 2, clean the citrus and freeze-dry it, then crush it to 80 mesh, add water to the citrus powder and ultrasonically treat it for 40 minutes, and then put it into a steam distillation device to distill the citrus essential oi...

Embodiment 3

[0035] A kind of foamed plastics for automotive interior, comprising the following raw materials in parts by weight: 118 parts of melamine resin, 16 parts of polyvinyl acetal, 23 parts of starch, 18 parts of cellulose, 10 parts of surfactant, 9 parts of foaming agent, 3.5 parts of crosslinking agent, 15 parts of curing agent, 10.6 parts of methacrylic acid, 18 parts of methyl benzoate, 16 parts of acrylonitrile and 7 parts of citrus. The particle size of cellulose is 260um.

[0036] The preparation method of the foamed plastics for the automotive interior, the specific steps are as follows:

[0037] Step 1, mixing melamine resin and polyvinyl acetal and carrying out condensation reaction at a pH value of 8.8 and a catalyst condition to obtain a condensation product;

[0038] Step 2: Clean the citrus and freeze-dry it, then crush it to 90 mesh, add water to the citrus powder and treat it with 30KHz and 660W ultrasound for 40 minutes, and then put it into a steam distillation d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com