Composite soil passivating agent

A passivating agent and soil technology, applied in the direction of soil conditioning materials, restoration of polluted soil, fertilizer mixture, etc., can solve the problems of poor removal effect of heavy metal ions, etc., and achieve small particle size, easy absorption, high reactivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

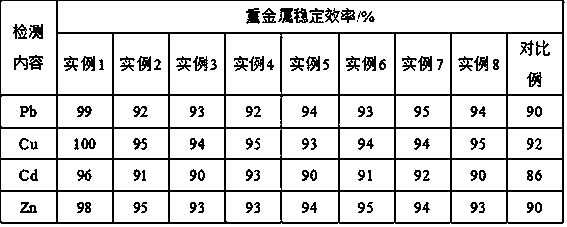

Examples

example 1

[0019] Put the steel slag in a steel slag grinder and pass it through a 300-mesh sieve to obtain steel slag powder. Put the steel slag powder and sulfuric acid with a mass fraction of 50% in a No. 1 beaker at a speed of 500r / min. , stirred and mixed for 60 minutes to obtain a mixed solution, and then filtered the mixed solution to obtain a filter residue, and then washed the filter residue with deionized water for 5 times, then placed the washed filter residue in an oven, and dried it at a temperature of 110°C until Constant weight, obtains modified steel slag powder; In parts by weight, 100 parts of deionized water, 6 parts of Bacillus pasteurianus, 15 parts of glycerol, 10 parts of ethylene glycol are placed in No. 2 beakers, and at a speed of 500r Under the condition of stirring and mixing for 40 minutes, the bacteria liquid of Bacillus pasteuriani was obtained; put the gum arabic powder and water into the No. Move the No. 3 beaker into a magnetic stirrer with digital displ...

example 2

[0021]Steel slag is placed in a steel slag grinder to pulverize, and a 300-mesh sieve is passed to obtain steel slag powder; in parts by weight, 100 parts of deionized water, 6 parts of Bacillus pasteurianus, 15 parts of glycerin, and 10 parts of ethylene glycol are placed in 2 In the No. 3 beaker, under the condition of rotating speed of 500r / min, stir and mix for 40 minutes to obtain the Bacillus pasteurian bacteria liquid; add the gum arabic powder and water into the No. 3 beaker according to the mass ratio of 1:100, and stir and mix with a glass rod for 30 minutes Finally, let it stand for swelling for 4 hours, then move the No. 3 beaker into a magnetic stirrer with digital display speed measurement and constant temperature, and heat and stir to dissolve for 50 minutes at a temperature of 100 ° C and a speed of 500 r / min to obtain gum arabic solution; Using a dropping funnel, add 30 parts of octenyl succinic anhydride dropwise to a three-necked flask containing 40 parts of ...

example 3

[0023] Put the steel slag in a steel slag grinder and pass it through a 300-mesh sieve to obtain steel slag powder. Put the steel slag powder and sulfuric acid with a mass fraction of 50% in a No. 1 beaker at a speed of 500r / min. , stirred and mixed for 60 minutes to obtain a mixed solution, and then filtered the mixed solution to obtain a filter residue, and then washed the filter residue with deionized water for 5 times, then placed the washed filter residue in an oven, and dried it at a temperature of 110°C until Constant weight to obtain modified steel slag powder; add gum arabic powder and water into the No. 3 beaker at a mass ratio of 1:100, stir and mix with a glass rod for 30 minutes, let it stand for swelling for 4 hours, and then move the No. 3 beaker into the digital display to measure the speed With a constant temperature magnetic stirrer, at a temperature of 100°C and a rotating speed of 500r / min, heat and stir to dissolve for 50 minutes to obtain gum arabic; Add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com