Rate type lithium ion battery anode composite and preparation method thereof

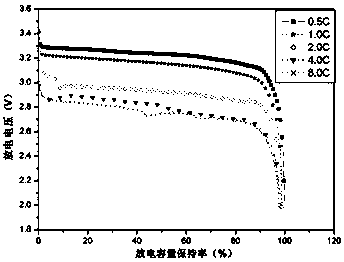

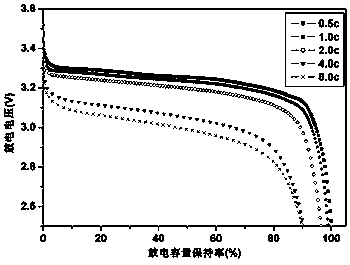

A lithium-ion battery and composite material technology, which is applied in the preparation of lithium-ion battery materials and battery materials, can solve the problems of poor rate performance and other problems, and achieve the effects of improving rate performance, easy control, and reducing accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step 1. the preparation method of inorganic lithium compound compound liquid and hard carbon solution;

[0024] A) The preparation method of the inorganic lithium compound compound liquid;

[0025] In a nitrogen atmosphere, weigh 8g of lithium carbonate, 2g of carbon nanotubes, and 1g of sodium dodecylbenzenesulfonate and add them to 500g of ethanol and stir to make it uniform;

[0026] B) Preparation method of hard carbon solution

[0027] Dissolve 80g of thermosetting phenolic resin material in 500g of ethanol organic solvent and stir evenly;

[0028] Step 2. Preparation of graphite inorganic / lithium composite:

[0029] Weigh 150g of artificial graphite powder with a particle size D50 of 10µm and a sphericity of 0.8, add it to the inorganic lithium compound compound liquid, and mill the graphite in a ball mill for 3 hours. After mixing evenly, stir at 80°C for 2 hours under stirring, and then cool , sieving to obtain graphite inorganic / lithium composite;

[0030] ...

Embodiment 2

[0033] Step 1. the preparation method of inorganic lithium compound compound liquid and hard carbon solution;

[0034] A) Preparation method of inorganic lithium compound compound solution:

[0035] In a helium atmosphere, weigh 5g of lithium hydroxide, 1g of carbon nanotubes, and 0.5g of sodium dodecylbenzenesulfonate and add them to 500g of ethanol and stir evenly to obtain an inorganic lithium compound compound solution;

[0036] B) Preparation method of hard carbon solution

[0037] Dissolve 50g of epoxy resin material in 500g of chloroform organic solvent and stir evenly to obtain hard carbon solution;

[0038] Step 2. Preparation of graphite / inorganic lithium composite:

[0039] Weigh 100g of natural graphite powder with a particle size D50 of 8µm and a sphericity of 0.6, add it to the inorganic lithium composite solution A, and mill the graphite in a ball mill for 1 hour. After mixing evenly, stir at 50°C for 2 hours under stirring, and then cool , sieving to obtain ...

Embodiment 3

[0043] Step 1. the preparation method of inorganic lithium compound compound liquid and hard carbon solution;

[0044] A) Preparation method of inorganic lithium compound compound solution:

[0045] In argon, weigh 10g of lithium metaaluminate powder, 2g of carbon nanotubes, and 1g of sodium dodecylbenzenesulfonate and add them to 500g of ethanol and stir evenly to obtain an inorganic lithium composite solution;

[0046] B) Preparation method of hard carbon solution

[0047] Dissolve 100g of phenolic resin polymer material in 500g of N-methylpyrrolidone organic solvent and stir to obtain a hard carbon solution;

[0048] Step 2. preparation of graphite inorganic lithium complex:

[0049] Then weigh 200g of artificial graphite powder with a particle size D50 of 12µm and a sphericity of 0.9, add it to the inorganic lithium composite solution, and mill the graphite in a ball mill for 5 hours. After mixing evenly, stir at 100°C for 2 hours under stirring, and then cool , sieving...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com