Dicing sheet and method for producing dicing sheet

A technology for cutting slices and thin films, which is applied in chemical instruments and methods, thin film/sheet adhesives, semiconductor/solid device manufacturing, etc., and can solve the problems of increased production of filamentous cutting slices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

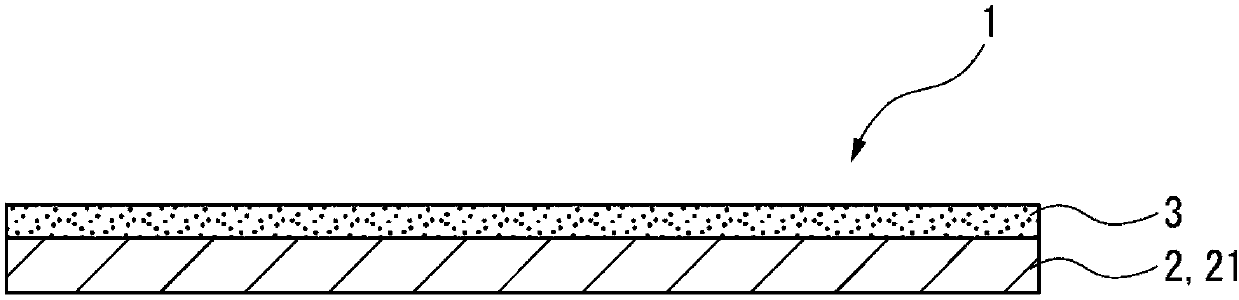

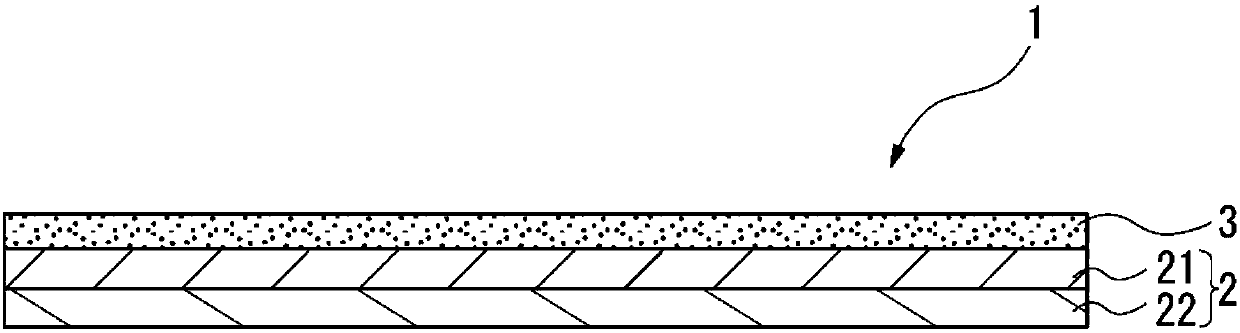

Image

Examples

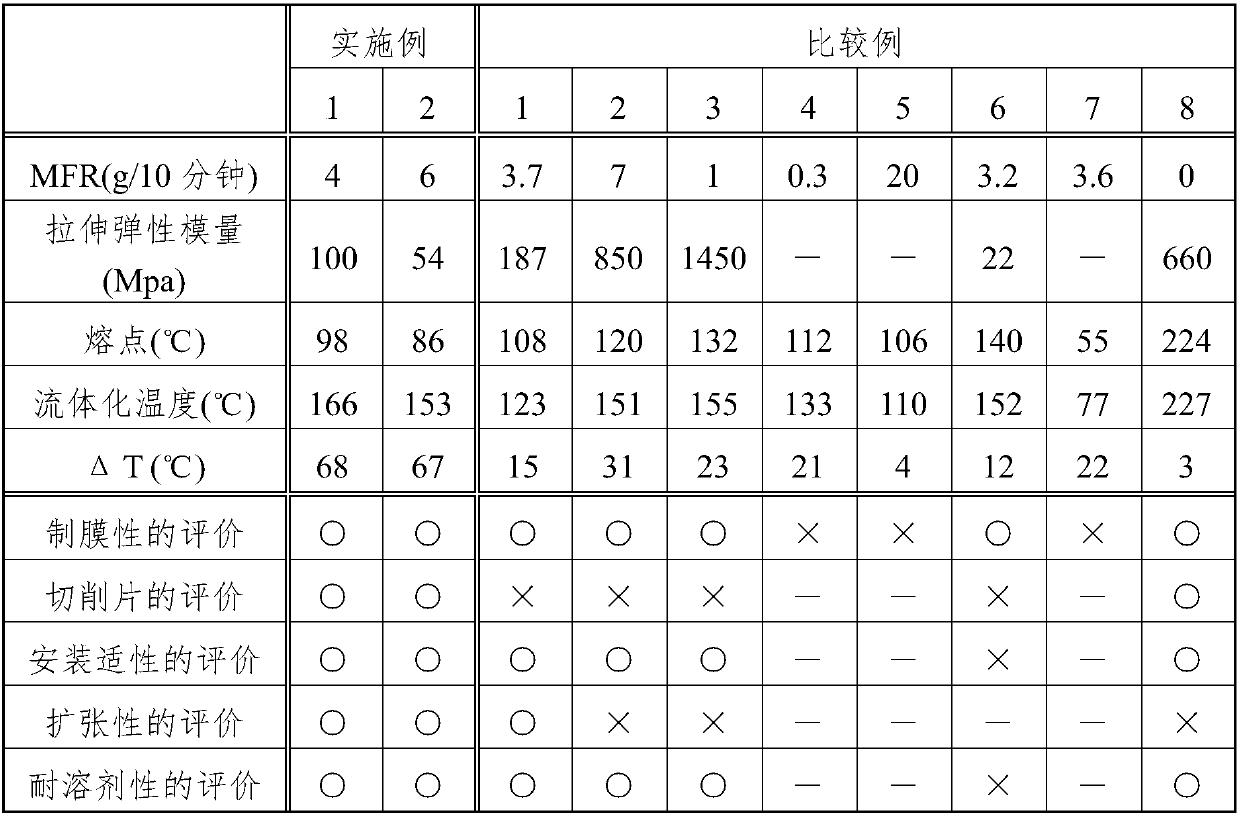

Embodiment 1

[0099] 1. Fabrication of Substrate Film

[0100] An ethylene-based copolymer comprising ethylene and a radically polymerizable acid anhydride as constituent units, a polyol compound having two or more hydroxyl groups, and a reaction accelerator that promotes a temperature-dependent dynamic covalent bond bonding reaction and dissociation reaction The thermoplastic resin is a thermoplastic resin (manufactured by Japan Polyethylene Corporation, product Name "Rexpearl ES323Y", temperature 190 ℃ and melt flow rate when load 2.16kg: 4g / 10 minutes) with small T-die extruder (TOYO Seiki Seisaku-Sho., Ltd., product name "Labo Plasto Mill ”) extrusion molding to obtain a substrate film formed of a resin layer with a thickness of 80 μm.

[0101] 2. Preparation of Adhesive Composition

[0102] 100 parts by mass of copolymer (Mw: 500,000) formed by copolymerizing 95 parts by mass of n-butyl acrylate and 5 parts by mass of acrylic acid, 120 parts by mass of urethane acrylate oligomer (Mw:...

Embodiment 2

[0106] An ethylene-based copolymer comprising ethylene and a radically polymerizable acid anhydride as constituent units, a polyol compound having two or more hydroxyl groups, and a reaction accelerator that promotes a temperature-dependent dynamic covalent bond bonding reaction and dissociation reaction Thermoplastic resins other than thermoplastic resins (manufactured by Japan Polyethylene Corporation) in which carboxyl groups derived from the above-mentioned radically polymerizable anhydrides of the above-mentioned ethylene-based copolymers and hydroxyl groups of the above-mentioned polyol compounds form ester bonds in the presence of the above-mentioned reaction accelerators are used. , product name "Rexpearl ES333Y", melt flow rate at a temperature of 190° C. and a load of 2.16 kg: 6 g / 10 minutes), a cut sheet was obtained in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com