Wire slot production technology for subway evacuation platform and production line thereof

An evacuation platform and production process technology, applied in manufacturing tools, cement mixing devices, ceramic molding workshops, etc., can solve the problems of inability to meet the quality requirements of imitation stone decorative plates, the impact of the plate on product quality, and the difficulty of internal air bubbles, and achieve product densification. The effect of improving the degree, reducing errors, and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0085] The production process method is:

[0086] S1. Mix and stir the raw materials and additives evenly to form a cement-based mixture material with high viscosity and low fluidity;

[0087] S11. The non-liquid raw materials in the silo 5 are respectively measured and transported to the self-unloading measuring bucket 2, and the measured steel fibers are added;

[0088] S12, input all the non-liquid raw materials into the mixer 3, and pre-mix the powder;

[0089] S13, adding the measured liquid additive at the same time to form a mixed liquid;

[0090] S14. Thoroughly stir the mixed solution to form a cement-based mixture material with high viscosity and low fluidity.

[0091] S2. Accurately measure and inject materials into the mold;

[0092] S3. Pass the mold with material through the continuous vibration of the roller table of the continuous vibrating table 6 to realize the preliminary leveling of the material and the discharge of air bubbles, and the preliminary forma...

Embodiment 3

[0105] S1. Mix and stir the raw materials and additives evenly to form a cement-based mixture material with high viscosity and low fluidity;

[0106] S11. The non-liquid raw materials in the silo 5 are respectively measured and transported to the self-unloading measuring bucket 2, and the measured steel fibers are added;

[0107] S12, input all the non-liquid raw materials into the mixer 3, and pre-mix the powder;

[0108] S13, adding the measured liquid additive at the same time to form a mixed liquid;

[0109] S14. Thoroughly stir the mixed solution to form a cement-based mixture material with high viscosity and low fluidity.

[0110] S2. Accurately measure and inject materials into the mold;

[0111] S3. Pass the mold with material through the continuous vibration of the roller table of the continuous vibrating table 6 to realize the preliminary leveling of the material and the discharge of air bubbles, and the preliminary formation of the component;

[0112] The step S3...

Embodiment 4

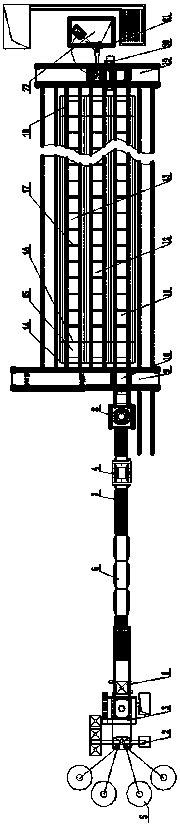

[0128] The present invention is a cable groove production line for subway evacuation platforms, and a cable groove production line for subway evacuation platforms, including sequentially connected material distribution devices, component forming devices and tunnel kiln maintenance devices;

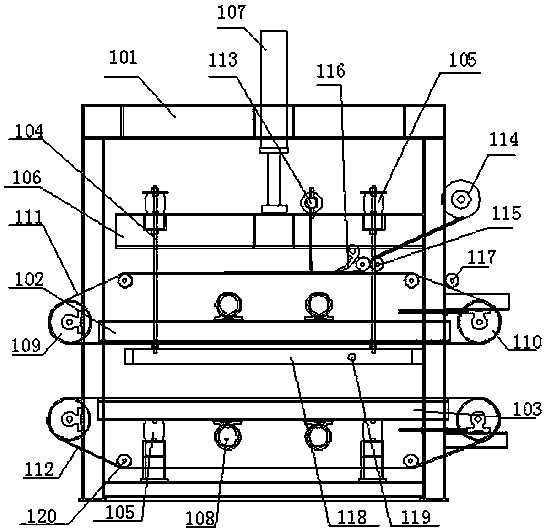

[0129] The distributing device includes a silo 5, a mixer 3 and a precision feeding device 1, a mixer 3 is disposed below the silo 5, and a precision feeding device 1 is configured below the mixer 3; the precision feeding device 1 includes a self-propelled Walking feeding unit, conveying unit below the feeding unit and automatic lifting weighing unit on the conveying unit;

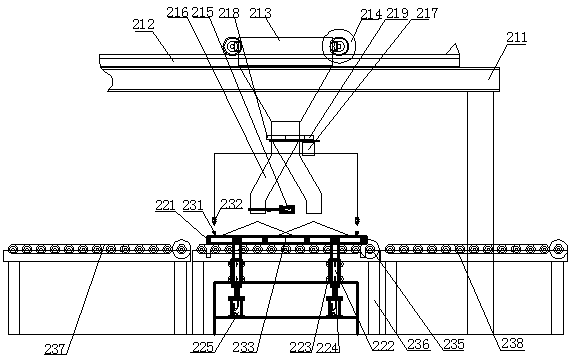

[0130] The self-propelled feeding unit includes a guide rail 212, a hopper traveling support 211, a distribution hopper 213, a traveling motor 214 and a discharge valve 215. The guide rail 212 is arranged in parallel directly above the horizontal roller, and the distribution hopper 213 is installed on the hopper traveli...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap