Reuse and up-to-standard discharging process of recycled water for chemical fiber viscose waste water

A waste water and viscose technology, which is applied in the direction of oxidized water/sewage treatment, water/sewage treatment, biological water/sewage treatment, etc., can solve the problems of large amount of waste water, hazards to the surrounding environment, and pollutant content that cannot meet the discharge standards. To achieve the effect of reducing pollution and using resources efficiently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

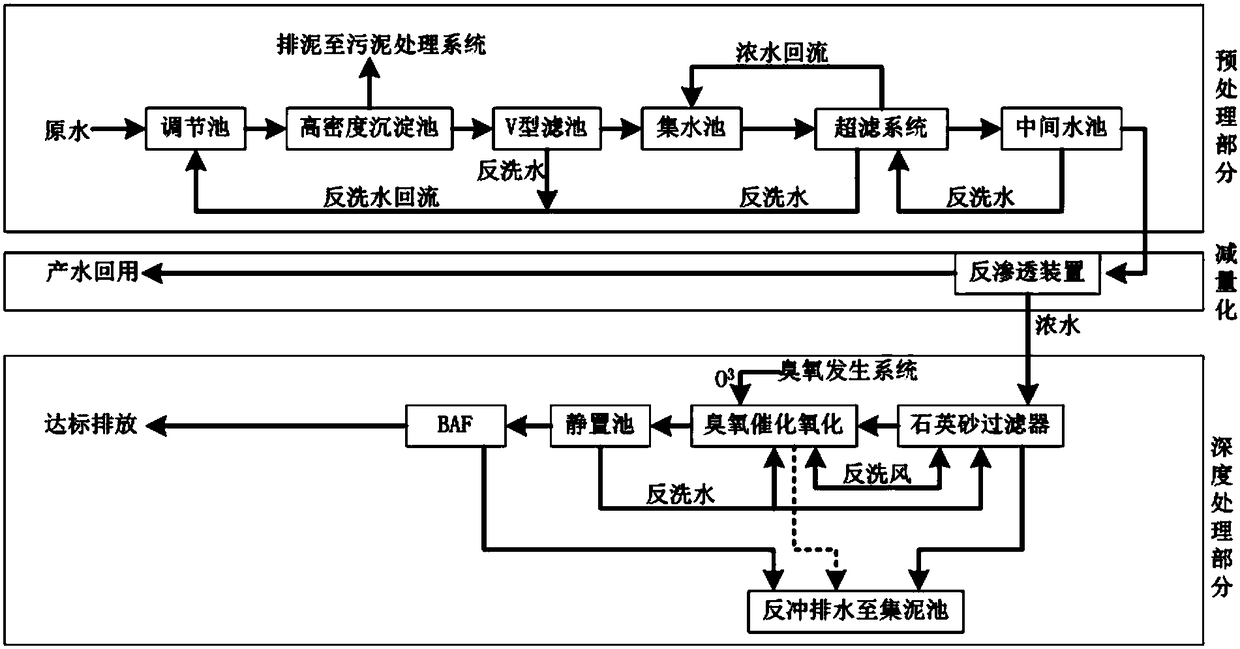

[0030] For a project in Sichuan, the entire system was installed and then put into operation. The water entering the system is water from chemical fiber viscose wastewater, the hardness (as CaCO 3 meter) content of 1600mg / L, COD Cr The content is 63mg / L, the raw water TDS is about 9470mg / L, and the turbidity is about 10NTU. For this water quality, such as figure 1Shown, apply above-mentioned technology of the present invention, the front coagulation water distribution unit of pretreatment part high-density sedimentation tank adds lime 9.6mg / L, soda ash 978mg / L, coagulant PAC10mg / L, and medicament mixes rapidly with influent, then Enter the reaction tank, add the flocculant PAM1mg / L at the bottom of the turbine blade in the reaction tank, large and dense alum flowers are formed in the water, and the wastewater enters the pre-sedimentation concentration tank, most of the suspended solids are precipitated and concentrated in this area, and the produced water enters the In the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com