A refrigeration absorbent and waste heat-driven absorption deep refrigeration method

A deep refrigeration and absorbent technology, which is applied in refrigerators, adsorption machines, refrigeration and liquefaction, etc., can solve the problems of general, large energy consumption, and pollution of the environment, and achieve low specific heat capacity, stable and efficient work, and no labor The effect of mass entrainment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

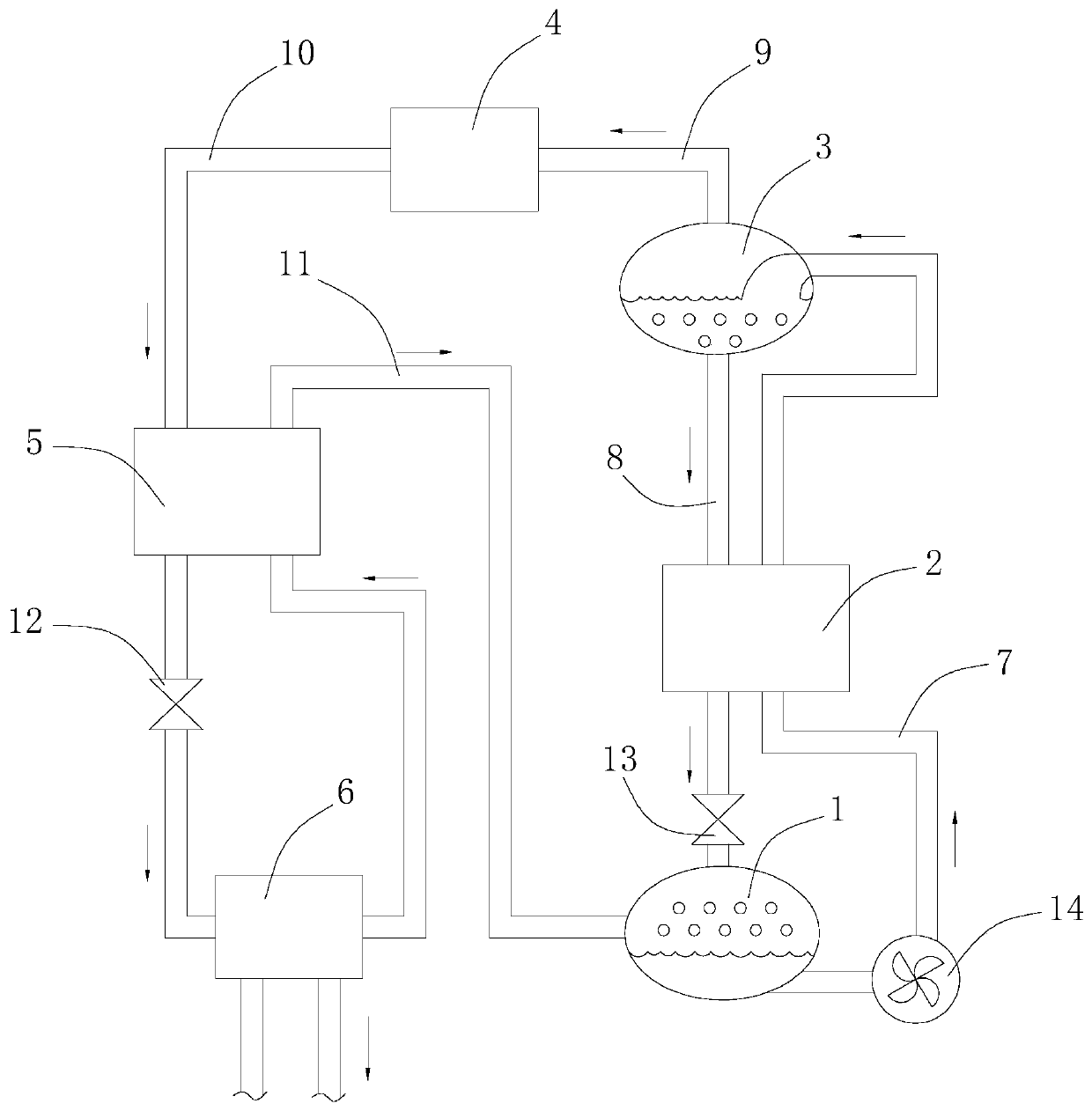

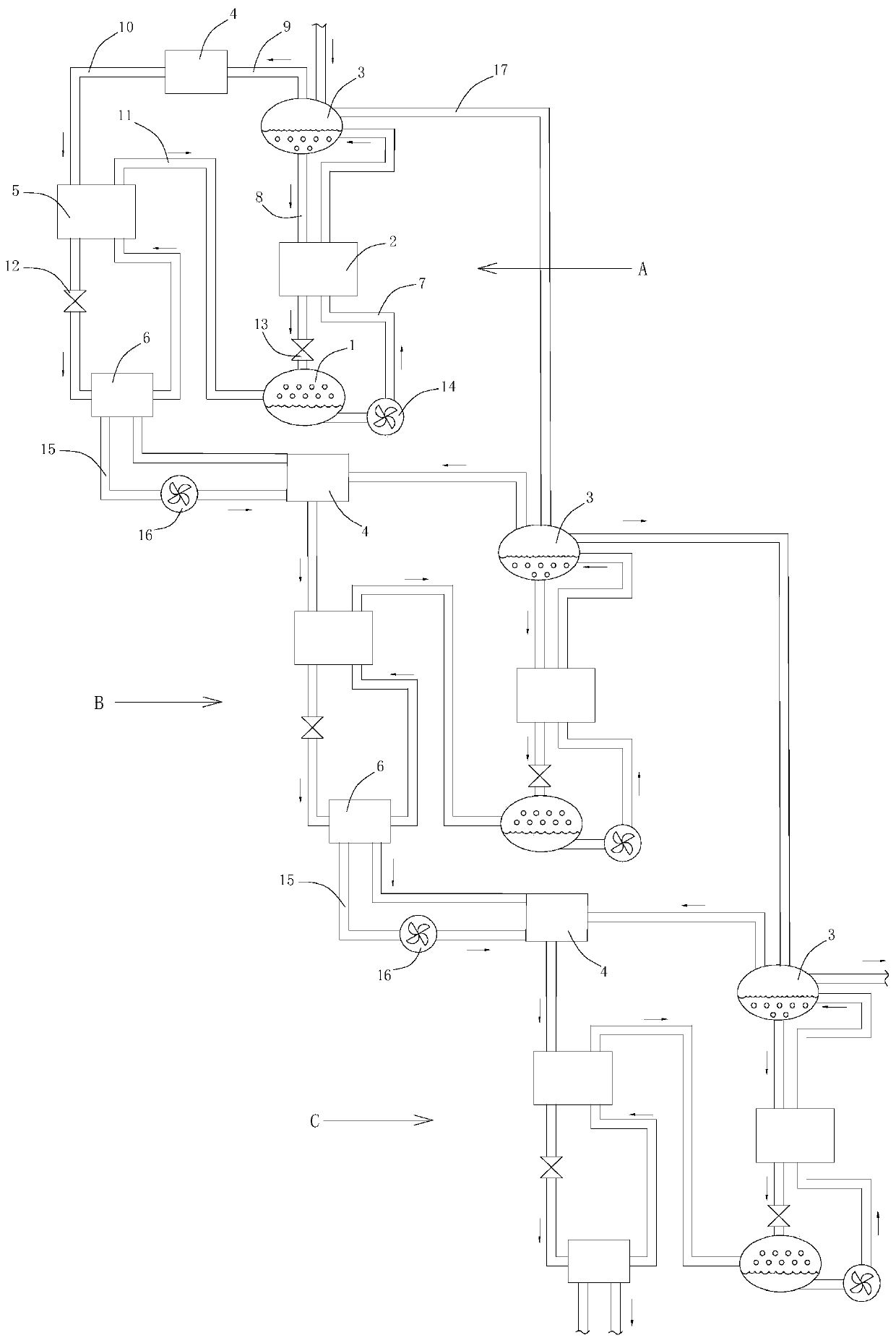

Method used

Image

Examples

Embodiment 1

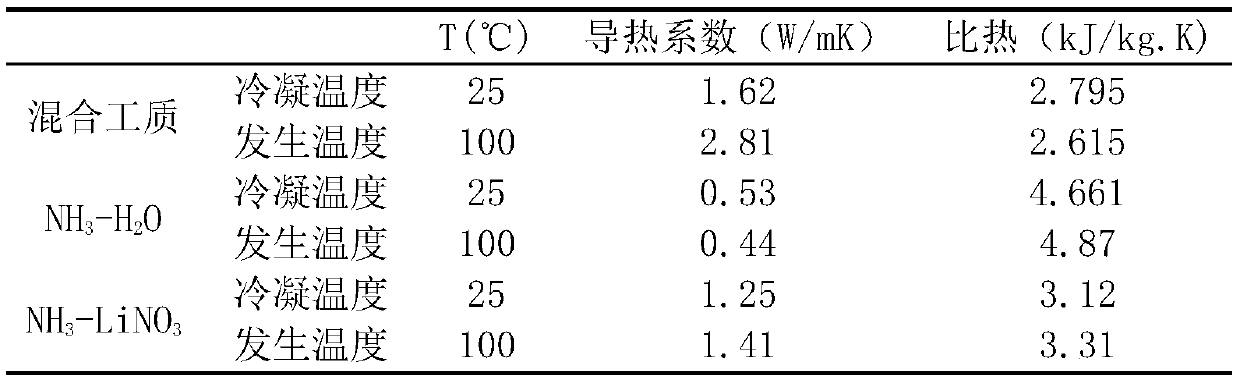

[0025] A kind of mixed refrigeration absorbent provided by this embodiment, its component comprises 30% ammonia (NH 3 ), 20% water (H 2 O), 30% lithium chromate (Li 2 CrO 4 ), 5% sodium iodide (NaI), 10% potassium hydroxide (KOH), 5% dimethylformamide (C 3 h 7 NO).

Embodiment 2

[0027] A kind of mixed refrigeration absorbent provided by this embodiment, its component comprises 60% ammonia (NH 3 ), 5% lithium chromate (Li 2 CrO 4 ), 22% sodium iodide (NaI), 10% potassium hydroxide (KOH), 3% dimethylformamide (C 3 h 7 NO).

Embodiment 3

[0029] A kind of mixed refrigeration absorbent provided by this embodiment, its component comprises 30% ammonia (NH 3 ), 5% lithium chromate (Li 2 CrO 4 ), 5% sodium iodide (NaI), 55% potassium hydroxide (KOH), 5% dimethylformamide (C 3 h 7 NO).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com