Variable heat source model-based non-circular-profile workpiece high-speed grinding temperature prediction method

A heat source model, grinding temperature technology, applied in radiation pyrometry, calorimeter, measuring device, etc., can solve the problem of decreased fatigue resistance, local temperature increase in grinding arc area, affecting the surface integrity of non-circular contour workpieces. Sexual use performance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

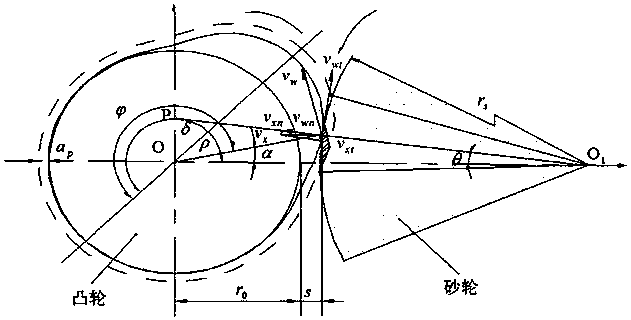

[0076] The test piece used in this example is a th465 camshaft in an automobile engine. The material is chilled alloy cast iron (HT250GB9439-88). There are 4 cylinders and 8 cams, which are intake and exhaust respectively. The contour profile of the cam is relatively complex, and its profile is generally composed of a base circle segment, a lift segment, a peach tip, and a return segment. Therefore, the grinding process of the cam is a typical processing of non-circular contour complex surface parts. The relevant parameters of th465 camshaft parts are shown in the table.

[0077] Table 1

[0078]

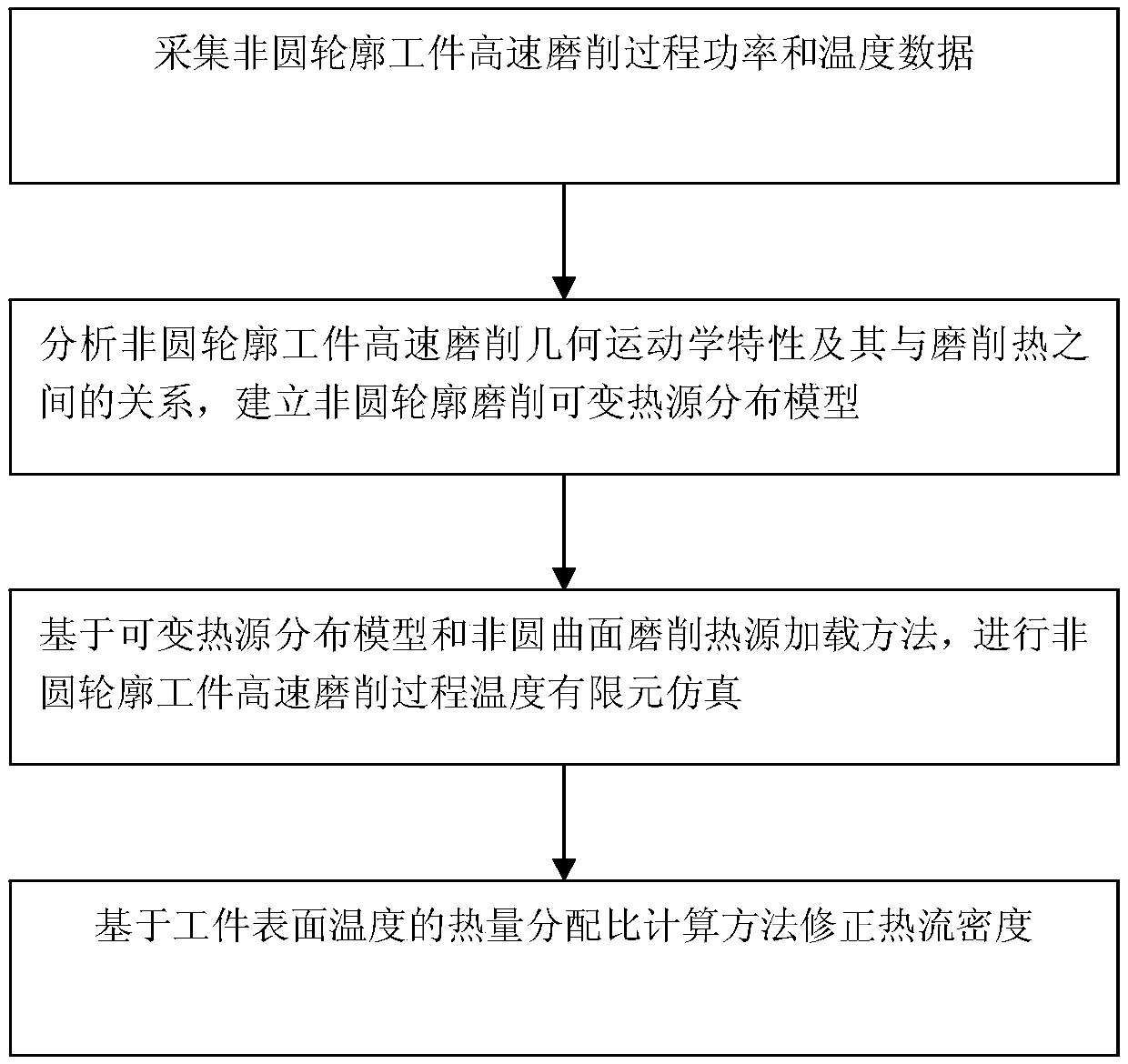

[0079] A method for predicting the temperature of high-speed grinding workpieces with non-circular contours based on a variable heat source model, such as figure 1 shown, including the following steps:

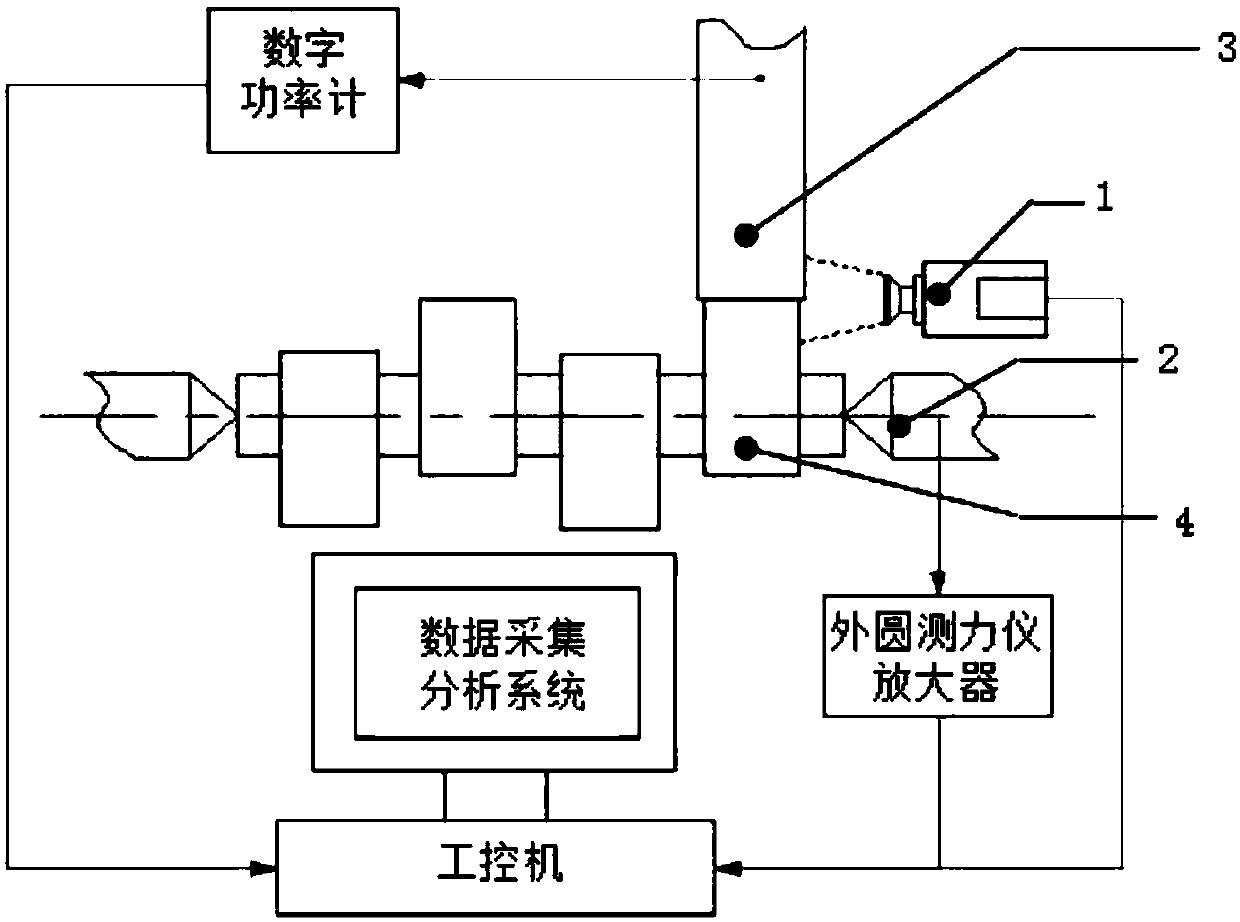

[0080] Step 1: Collect power and temperature dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com