Numerical control machine tool for thread milling and thread milling processing method

A CNC machine tool and milling processing technology, applied in the field of metal cutting processing, can solve problems such as inability to meet processing requirements, achieve the effects of reducing error probability and programming time, improving efficiency, improving quality and processing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

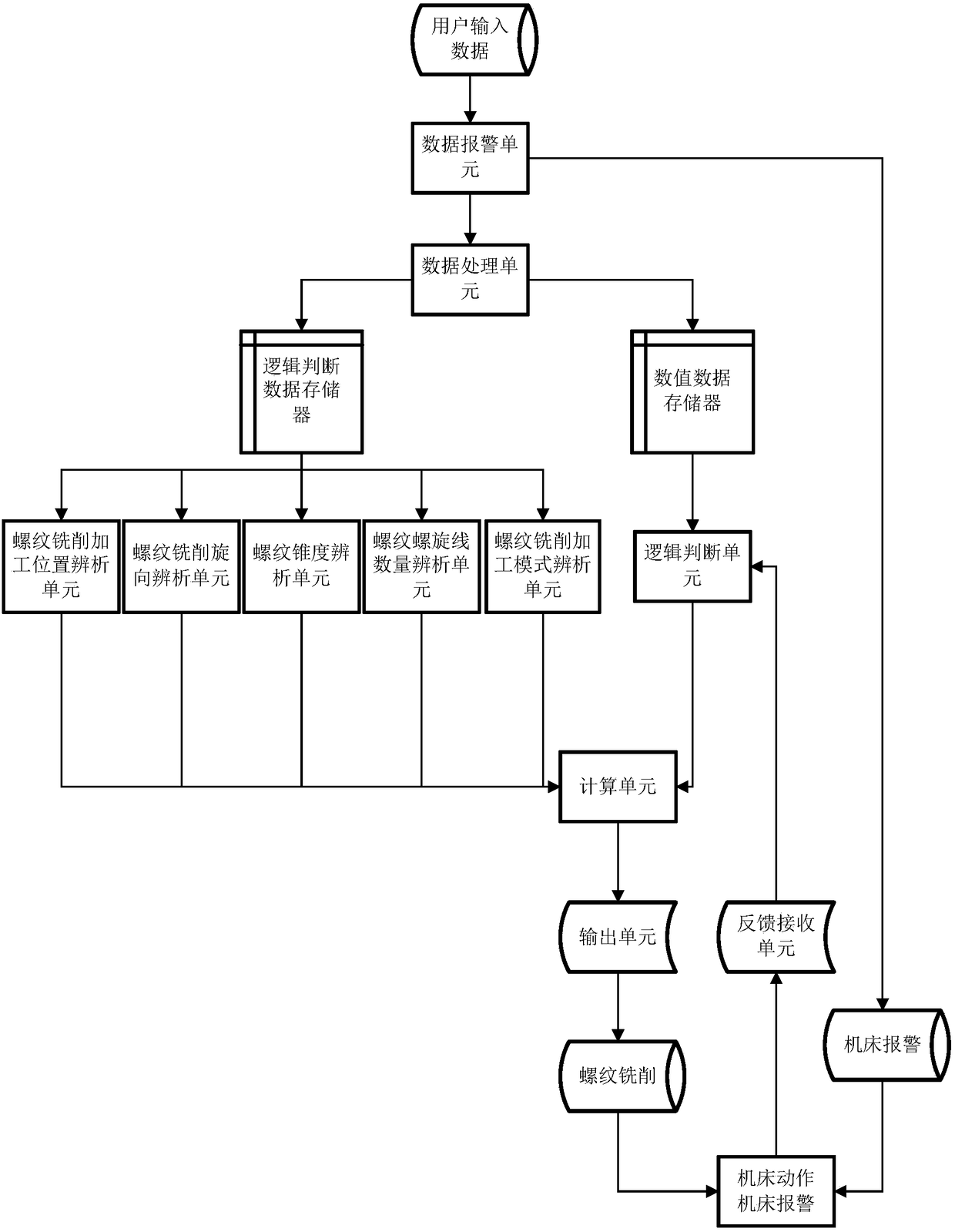

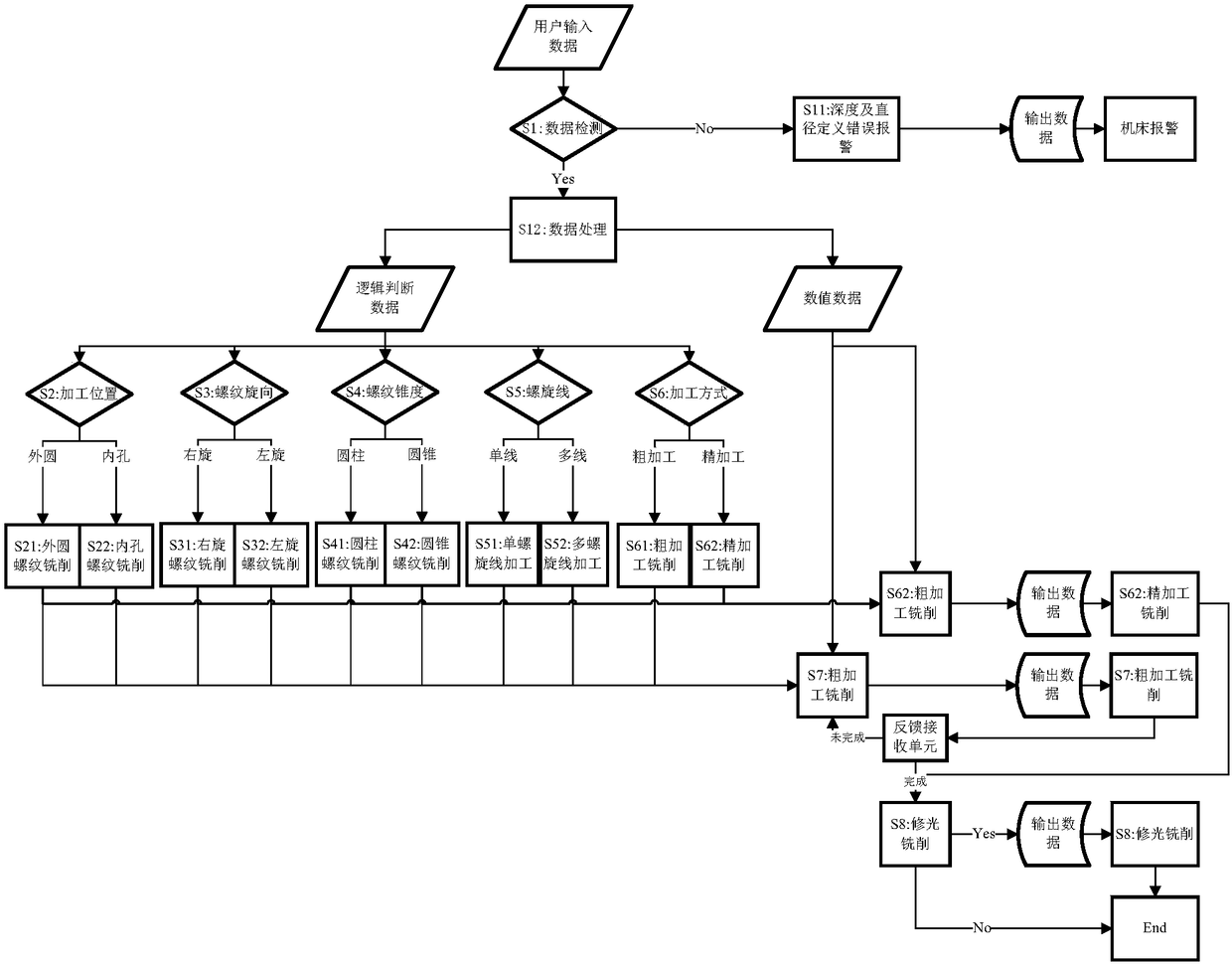

Method used

Image

Examples

example 1

[0130] Example 1, large diameter thread milling.

[0131] Processing analysis: In the connection of large parts, larger diameter screw holes will be used. The price of a single tap can exceed 10,000, and the cost can be reduced by thread milling.

[0132] At the same time, stainless steel or even titanium alloy parts are used in large parts used in wind power and other fields, and the blank cost of a single part is relatively high. Rough machining + finishing + smoothing machining in a continuous decreasing manner can effectively control the quality of screw hole processing.

[0133] The following is a processing case of the M100 exhaust valve screw hole in the cylinder head of a marine low-speed diesel engine.

[0134] Processing setting: set the thread milling processing position as the inner hole, set the thread milling direction as right-handed, set the thread taper as 0, set the number of helixes as 1, and set the processing method as rough machining + finishing + Finis...

example 2

[0139] Example 2, NPT 2” American standard tapered pipe thread.

[0140] Processing analysis: the M10 lifting screw hole of the marine fuel distribution block is a left-handed thread;

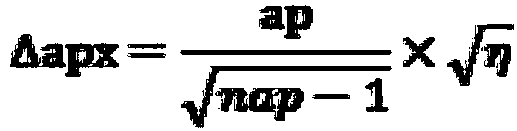

[0141] Processing setting: set the thread milling processing position as the inner hole, set the thread milling rotation direction as right-handed, set the thread taper as 1 / 16, set the number of helix lines as 1, and set the processing method as rough machining + finishing Processing + smoothing processing, set thread diameter to 60.09, set thread pitch to 11.45, set thread milling safety depth to 5, set thread milling start depth to 2, thread milling effective depth to 26.5, finishing allowance to 0.1 mm, the number of rough machining is 2 times, and the machining accuracy of taper thread is 0.5mm.

[0142] When the set diameter and depth logic relationship is wrong, the thread milling module will provide diameter and depth setting alarm signals to the CNC machine tool and notify the user of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com