Method for preparing zero-valent-nanoferrum loaded modified zeolite for deleading coal-fired flue gas

A technology of nanometer zero-valent iron and modified zeolite, which is applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve problems such as the inability to apply gas Pb elemental adsorption, lack of modified zeolite, etc., to increase surface tension, The effect of controllable reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

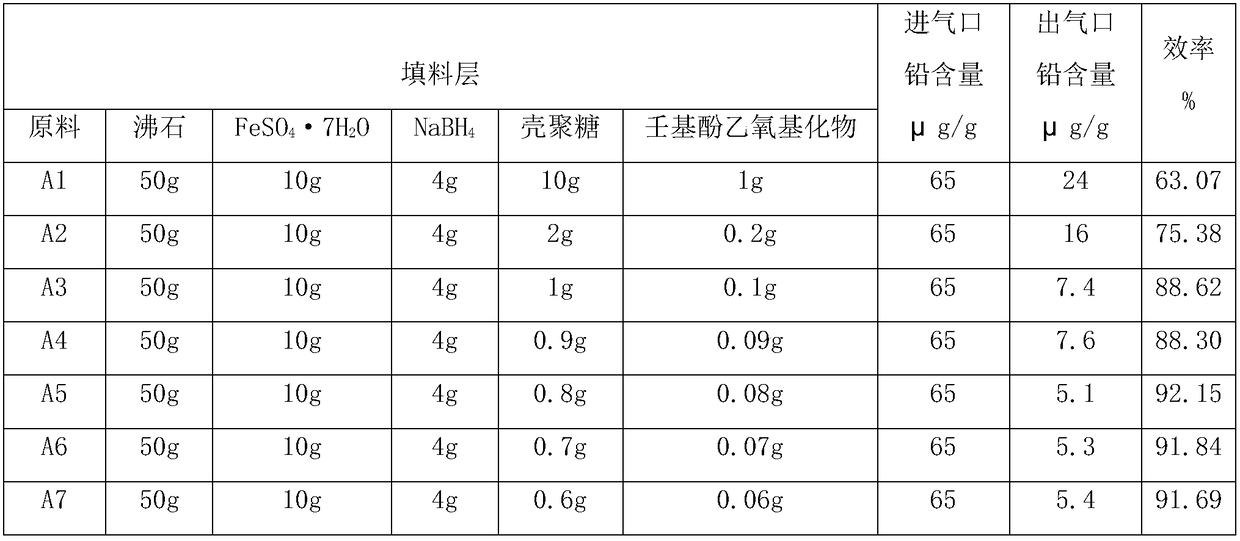

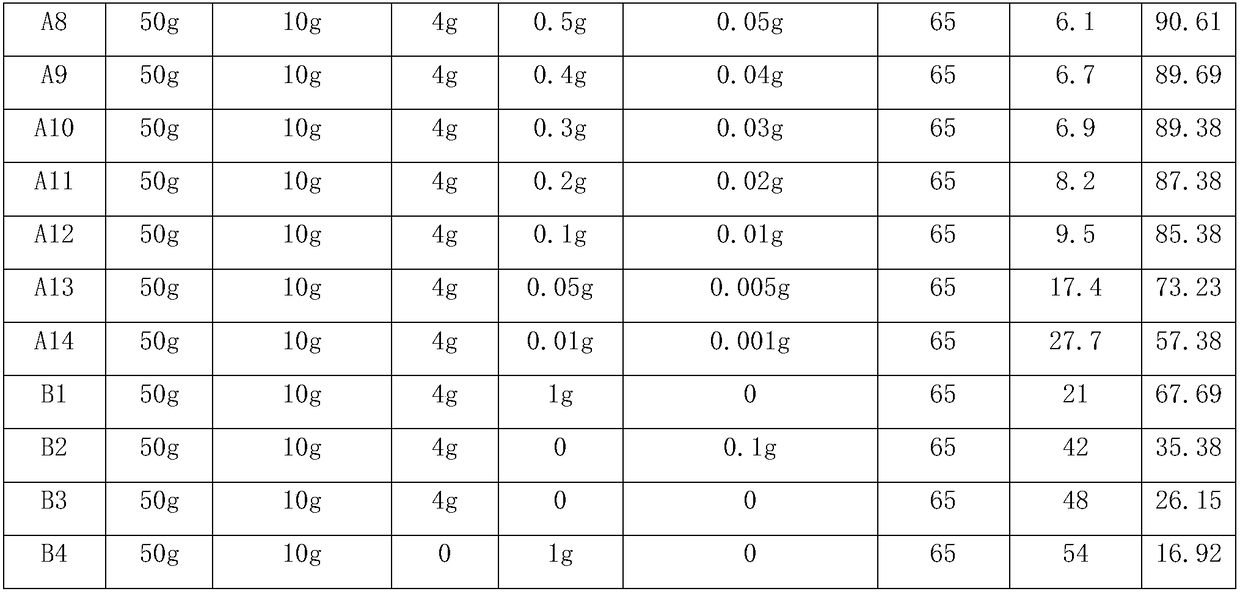

[0027] Example 1 Preparation of modified zeolite A1 loaded with nanometer zero-valent iron

[0028] (1) Pretreatment: 50 grams of zeolite with 1mol / L HNO 3 The solution was stirred for 12 hours, pickled to remove impurities, washed three times with deionized water and dried;

[0029] (2) Preparation of nano-iron: add 200 grams of deionized water to the pretreated zeolite in step (1), and then add FeSO 4 ·7H 2 O and 1mol / L HNO 3 The solution was adjusted to a pH of 2-5, and then a solution containing 4 g of NaBH 4 Configured 50ml reducing agent solution, and stirred at room temperature for 60 minutes to synthesize the zeolite loaded with nanometer zero-valent iron;

[0030] (3) Synthesis of modified zeolite loaded with nanometer zero-valent iron: add 10 grams of chitosan and 1 gram of 4-nonylphenol ethoxylate to the solution of step (2), and under ultrasonic conditions and 60 ℃ Stirred at a temperature of 60 minutes for 60 minutes to obtain black spherical particles;

[0...

Embodiment 2

[0032] Example 2 Preparation of modified zeolite A2 loaded with nanometer zero-valent iron

[0033] (1) Pretreatment: 50 grams of zeolite with 1mol / L HNO 3 The solution was stirred for 12 hours, pickled to remove impurities, washed three times with deionized water and dried;

[0034] (2) Preparation of nano-iron: add 200 grams of deionized water to the pretreated zeolite in step (1), and then add FeSO 4 ·7H 2 O and 1mol / L HNO3 The solution was adjusted to a pH of 2-5, and then a solution containing 4 g of NaBH 4 Configured 50ml reducing agent solution, and stirred at room temperature for 60 minutes to synthesize the zeolite loaded with nanometer zero-valent iron;

[0035] (3) Synthesis of modified zeolite loaded with nanometer zero-valent iron: add 2 grams of chitosan and 0.2 gram of 4-nonylphenol ethoxylate to the solution of step (2), and under ultrasonic conditions and 60 ℃ Stirred at a temperature of 60 minutes for 60 minutes to obtain black spherical particles;

[00...

Embodiment 3

[0037] Example 3 Preparation of modified zeolite A3 loaded with nanometer zero-valent iron

[0038] (1) Pretreatment: 50 grams of zeolite with 1mol / L HNO 3 The solution was stirred for 12 hours, pickled to remove impurities, washed three times with deionized water and dried;

[0039] (2) Preparation of nano-iron: add 200 grams of deionized water to the pretreated zeolite in step (1), and then add FeSO 4 ·7H 2 O and 1mol / L HNO 3 The solution was adjusted to a pH of 2-5, and then a solution containing 4 g of NaBH 4 Configured 50ml reducing agent solution, and stirred at room temperature for 60 minutes to synthesize the zeolite loaded with nanometer zero-valent iron;

[0040] (3) Synthesis of modified zeolite loaded with nanometer zero-valent iron: add 1 gram of chitosan and 0.1 gram of 4-nonylphenol ethoxylate to the solution of step (2), and under ultrasonic conditions and 60 ℃ Stirred at a temperature of 60 minutes for 60 minutes to obtain black spherical particles;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com