Nanocellulose gel, and preparation method and application of nanocellulose gel

A nanocellulose, cellulose technology, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve the problems of poor elastic properties, low water absorption of nanocellulose gels, etc. To achieve the effect of simple operation and easy large-scale preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a kind of preparation method of nanocellulose gel, comprises the following steps:

[0029] Mixing the cellulose material with sulfuric acid for hydrolysis reaction to obtain nanocellulose suspension;

[0030] Mixing the nanocellulose suspension with a crosslinking agent, an initiator, a binder and an accelerator to obtain a nanocellulose mixed solution;

[0031] The nanocellulose mixed solution is subjected to hydrothermal reaction to obtain nanocellulose gel.

[0032] In the invention, the cellulose material and sulfuric acid are mixed for hydrolysis reaction to obtain nano-cellulose suspension. In the present invention, the cellulosic material preferably includes cotton fiber, softwood pulp or hardwood pulp; in an embodiment of the present invention, cotton fiber is specifically used.

[0033] In the present invention, the mass concentration of the sulfuric acid is preferably 60-80%, more preferably 65-75%. In the present invention, the mass ...

Embodiment 1

[0047] Mix 10 g of cotton fiber with 100 mL of sulfuric acid with a mass concentration of 70%, and carry out a hydrolysis reaction in a 35°C water bath at 400 rpm for 3 hours, mix the obtained hydrolyzed material with 3000 mL of distilled water, and let it settle for 10 hours to obtain a supernatant and a lower layer Turbid liquid: pour out the supernatant, wash the remaining lower turbid liquid with distilled water, then centrifuge the resulting material 4 times to obtain a centrifuged material with a pH value of 2.0, wherein the supernatant obtained after each centrifugation Pour it away, wash the obtained lower layer turbid liquid with distilled water, and then perform the next centrifugation, the centrifugal speed is 6000rpm, and the time of single centrifugation is 20min; the obtained centrifuged material is dialyzed for 7 days with a molecular weight cut-off of 8000 to obtain the pH value The dialysis material is 7.0; the obtained dialysis material is concentrated to a na...

Embodiment 2

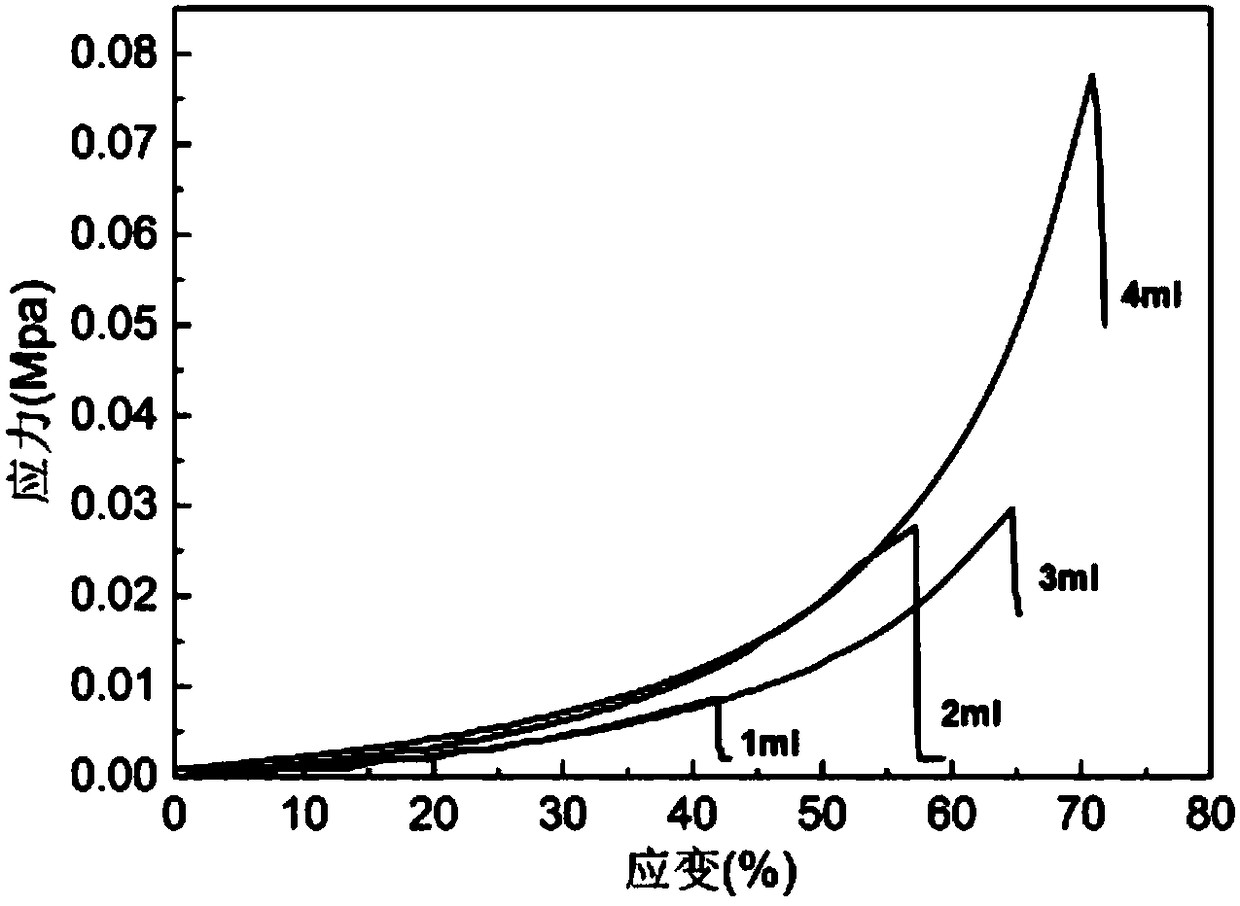

[0052] Nanocellulose gel was prepared according to the method of Example 1, wherein the addition amount of acrylic acid was 1, 2 and 3 mL respectively, and the elastic modulus test was carried out on the obtained nanocellulose gel and the nanocellulose gel prepared in Example 1, see results figure 2 . figure 2 is the compression-strain curve of nanocellulose gels with different acrylic acid content, by figure 2 It can be seen that when the elastic strain reaches 70%, the nanocellulose gel will break, and its elastic modulus can reach up to 0.821Mpa.

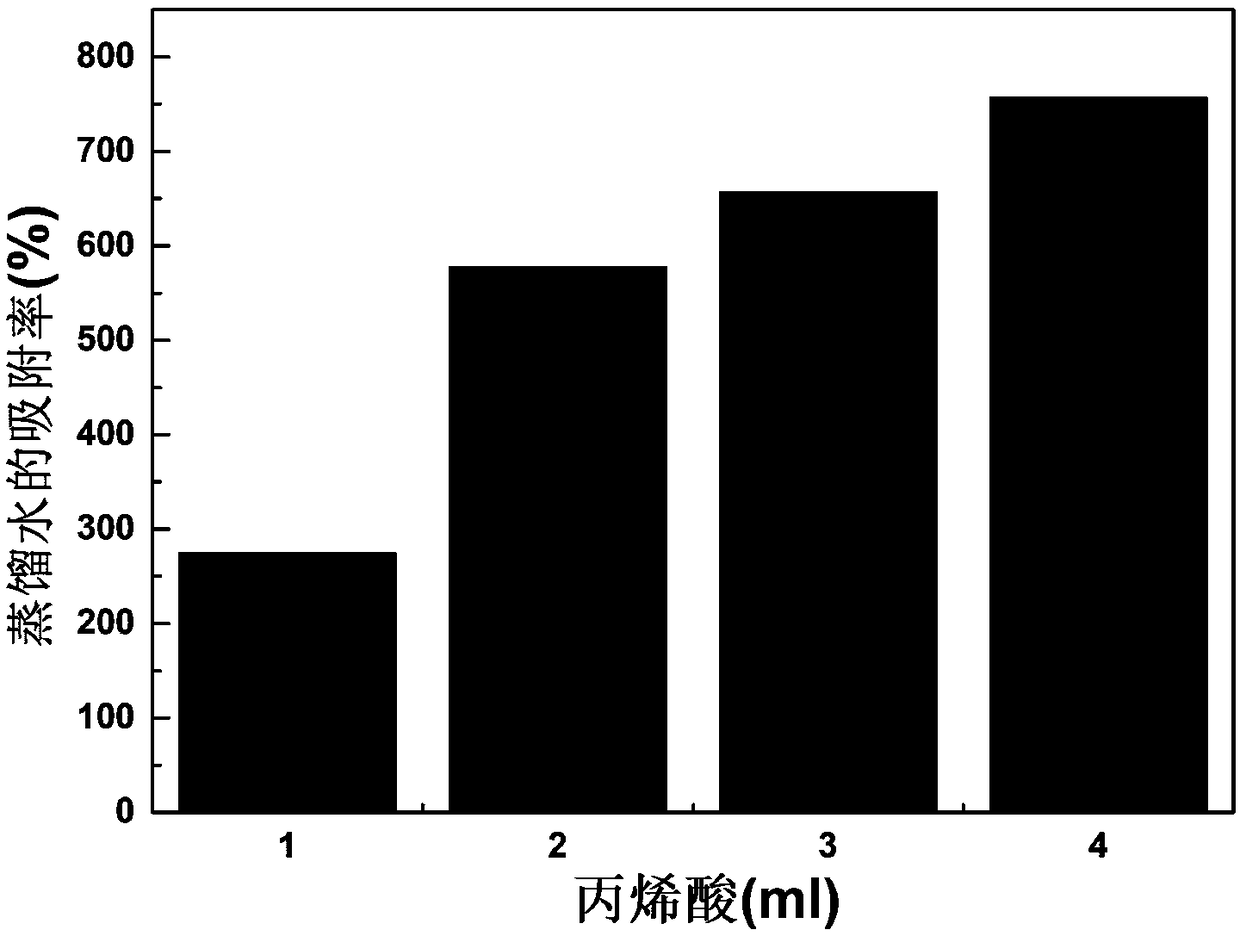

[0053] The nanocellulose gel prepared in Example 2 (the amount of acrylic acid added is 1, 2 and 3mL respectively) and the nanocellulose gel prepared in Example 1 were tested for water absorption, specifically, the nanocellulose gel was placed in enough distilled water until the nanocellulose gel reaches the swelling equilibrium state, then use filter paper to remove the moisture on the surface of the swollen nanocellulose g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com