Porcelainizable, halogen-free and flame-retardant EVA cable material and preparation method thereof

A technology of flame-retardant cable materials and inorganic flame retardants, which is applied in the field of plastic processing, can solve the problems of poor insulation of the vitrified layer, changes in appearance and size, and lack of protection, so as to achieve good insulation and flame retardancy. And the effect of suppressing smoke is remarkable, and the effect of ensuring normal transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

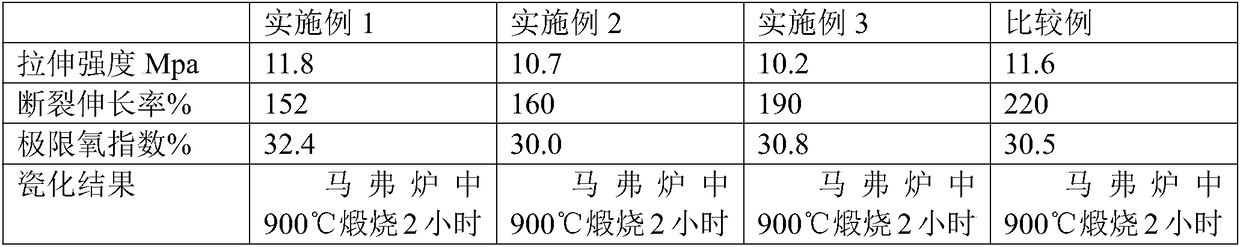

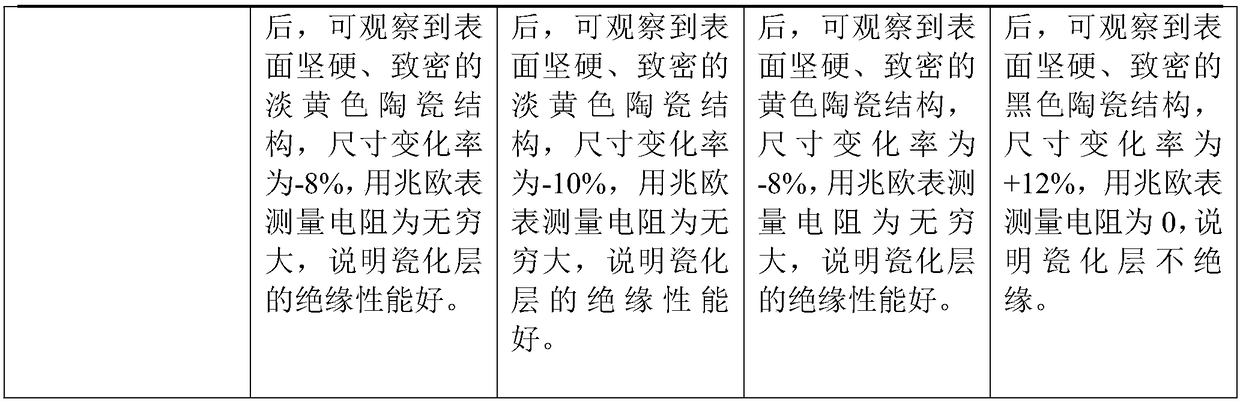

Examples

Embodiment 1

[0032] The preparation of porcelain EVA halogen-free flame-retardant cable material includes the following steps: (1) 1 part of lubricant, 120 parts of inorganic flame retardant, 40 parts of porcelain filler, 20 parts of silicate filler, high temperature cracking catalyst 2 parts were mixed in a high-speed mixer for 5 minutes, unloaded for later use; (2) 80 parts of EVA, 20 parts of LLDPE, 10 parts of silicone rubber / white carbon black, 6 parts of compatibilizer, 2 parts of silicone masterbatch, antioxidant Mix 10100.2 parts of the agent in a mixer at 150°C for 3 minutes, pour the powdered material mixed in step (1) into the mixer and continue mixing for 8 minutes, then unload; (3) Mix the mixture in step (2) The refined material is moved to a twin-screw extruder, melted and extruded at a temperature of 120-160°C and a screw speed of 100r / min, and granulated to obtain porcelain-able EVA halogen-free flame-retardant cable material. .

[0033] The weight ratio of silicone rubbe...

Embodiment 2

[0036] The preparation of porcelain-able EVA halogen-free flame-retardant cable material includes the following steps: (1) Mix 110 parts of inorganic flame retardant, 50 parts of ceramic filler, 20 parts of silicate filler, and 3 parts of high-temperature cracking catalyst at high speed (2) 80 parts of EVA, 20 parts of LLDPE, 15 parts of silicone rubber / white carbon black, 6 parts of compatibilizer, 3 parts of silicone masterbatch, 10100.2 parts of antioxidant, in Mix in an internal mixer at 150°C for 3 minutes; pour the powdered material mixed in step (1) into the internal mixer and continue mixing for 8 minutes, and then unload; (3) transfer the mixed material in step (2) to a twin-screw extruder, melt-extruded and granulated under the condition of extruder temperature of 120-160°C and screw speed of 100r / min, to obtain porcelain-able EVA halogen-free flame-retardant cable material.

[0037] The weight ratio of silicone rubber / white carbon black is 100:50, the inorganic flam...

Embodiment 3

[0040] The preparation of porcelain-able EVA halogen-free flame-retardant cable material includes the following steps: (1) 120 parts of inorganic flame retardant, 50 parts of ceramic filler, 20 parts of silicate filler, and 2 parts of high-temperature cracking catalyst are mixed at high speed Mix in the mixer for 5 minutes, unload for later use; (2) first mix 100 parts of EVA, 10 parts of silicone rubber / white carbon black, 8 parts of compatibilizer, 3 parts of silicone masterbatch, 1 part of lubricant, and 10100.2 parts of antioxidant Mix for 3 minutes in an internal mixer at 150°C; pour the powdered material mixed in step (1) into the internal mixer and continue mixing for 8 minutes, then unload; (3) Mix well in step (2) The material is moved to a twin-screw extruder, melt-extruded and pelletized under the conditions of extruder temperature 120-160°C and screw speed 100r / min, to obtain porcelain-able EVA halogen-free flame-retardant cable material.

[0041] The weight ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com