Environment-friendly fireproof coating for steel structure and preparation method thereof

A technology of fire-resistant coatings and steel structures, applied in fire-resistant coatings, anti-corrosion coatings, polyester coatings, etc., can solve the problems of unfavorable environmental protection construction personnel's health, environmental protection performance, insufficient weather resistance, and only focus on fire performance indicators, etc., to achieve comprehensive Good performance and performance stability, remarkable flame retardant and fireproof effects, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

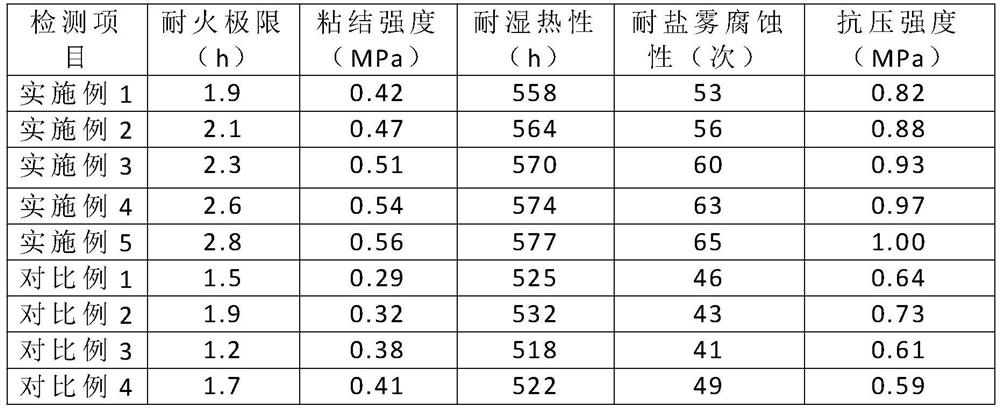

Examples

Embodiment 1

[0031] An environment-friendly fireproof coating for steel structures is characterized in that it is made of the following components in parts by weight: 20 parts of oxadiazole-based silane-based ion-type film-forming polymers, 10 parts of carboxyl-terminated hyperbranched polyesters, 8 parts of sulfonated phenoxycyclophosphazene, 3 parts of polyarylene oxadiazole fiber powder, 8 parts of white cement, 3 parts of attapulgite, 2 parts of phosphorus pentoxide, 1 part of defoamer, 1 part of leveling agent , 0.5 part of dispersant; The dispersant is sodium hexametaphosphate; The defoamer is tributyl phosphate; The leveling agent is a polyacrylate leveling agent; The white cement is a grade of White's white calcium aluminate cement.

[0032] The particle size of the attapulgite is 1000 mesh; the polyarylene oxadiazole fiber powder is Baodren short fiber powder; its average diameter is 1 μm, and the aspect ratio is 25; the carboxyl-terminated hyperbranched polyester is HyPer C10. ...

Embodiment 2

[0037] An environment-friendly steel structure fireproof coating is characterized in that it is made of the following components in parts by weight: 23 parts based on oxadiazole silyl based ion-type film-forming polymer, 11 parts of carboxyl-terminated hyperbranched polyester, Sulfonated phenoxycyclophosphazene 8.5 parts, polyarylene oxadiazole fiber powder 3.5 parts, white cement 9 parts, attapulgite 3.5 parts, phosphorus pentoxide 2.5 parts, defoamer 1.2 parts, leveling agent 1.3 parts , 0.7 part of dispersant; The dispersant is polycarboxylate sodium salt; The defoamer is the defoamer Deqian 3100; The leveling agent is cellulose acetate leveling agent; The white cement is the label It is 625 white Portland cement; the particle size of the attapulgite is 1050 mesh; the polyarylene oxadiazole fiber powder is Baodren short fiber powder; its average diameter is 2 μm, and the aspect ratio is 30; The carboxyl-terminated hyperbranched polyester is HyPer C20.

[0038] The preparat...

Embodiment 3

[0042] An environment-friendly fireproof coating for steel structures is characterized in that it is made of the following components in parts by weight: 25 parts of oxadiazole-based silane-based ion-type film-forming polymers, 13 parts of carboxyl-terminated hyperbranched polyesters, 9 parts of sulfonated phenoxycyclophosphazene, 4 parts of polyarylene oxadiazole fiber powder, 10 parts of white cement, 4 parts of attapulgite, 3 parts of phosphorus pentoxide, 1.5 parts of defoamer, 2 parts of leveling agent , 1 part of dispersant; said dispersant is sodium hexametaphosphate; said defoamer is defoamer BYK088; said leveling agent is polyvinyl butyral leveling agent; said white cement is labeled as 525 white Portland cement; the particle size of the attapulgite is 1100 mesh; the polyarylene oxadiazole fiber powder is Baodren short fiber powder; its average diameter is 2.5 μm, and the aspect ratio is 35.

[0043] The preparation method of the sulfonated phenoxycyclophosphazene com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com